Are you on the verge of choosing a submersible pump and find yourself confused between two-wire and three-wire options? You’re not alone.

Many homeowners and professionals face this dilemma when deciding on the right pump for their needs. The choice might seem technical, but it’s crucial for the efficiency and longevity of your water system. Understanding the differences between these two types can be the key to making a decision that saves you time, money, and future headaches.

This article will break down the complexities into simple, digestible insights, helping you make an informed choice without the technical jargon. Let’s dive into the essentials of two-wire versus three-wire submersible pumps and discover which one suits your needs best. Stick around to find out which option could be the game-changer for your water system.

Credit: www.youtube.com

Two Wire Submersible Pump

The two wire submersible pump is a popular choice for many. It’s simpler in design and often easier to install. This pump type is ideal for smaller, residential applications. It offers a convenient solution for basic water pumping needs.

Design And Components

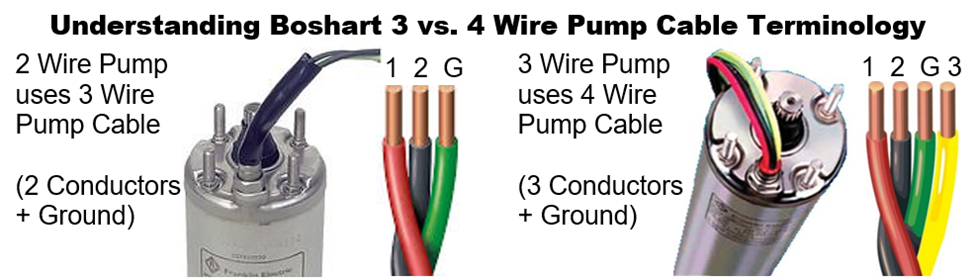

Two wire submersible pumps have a straightforward design. They contain fewer components than three wire pumps. The motor and pump are enclosed in a single unit. This design reduces the need for external control boxes. The two wires connect directly to the power source. This setup makes the pump easier to understand and maintain.

Installation Process

Installing a two wire submersible pump is simple. First, connect the two wires to the power supply. Ensure the wires are secure and insulated. Lower the pump into the water source carefully. Make sure it is fully submerged for optimal performance. Test the pump to check for proper operation.

Advantages

The two wire submersible pump has several benefits. Its design is simple and cost-effective. Fewer components mean less maintenance over time. Installation requires minimal technical knowledge. This pump is reliable for residential water needs. It’s compact, saving space and reducing clutter.

Disadvantages

This pump type has some limitations. It is not suitable for heavy-duty applications. The motor’s lifespan may be shorter without a control box. Troubleshooting issues can be challenging. It may lack advanced features found in other pumps. Consider these factors before choosing a two wire pump.

Three Wire Submersible Pump

Three wire submersible pumps have an external control box, unlike two wire pumps with built-in controls. This feature offers easier maintenance and repair, making them suitable for deeper wells. Understanding the differences helps choose the right pump for your needs.

If you’ve ever dipped your toes into the world of submersible pumps, you’ve likely encountered the debate between two-wire and three-wire models. Today, let’s dive into the specifics of three-wire submersible pumps. Known for their robust functionality and reliability, these pumps are a popular choice for those seeking efficiency in water management. But what makes them tick? And how do they fare in terms of installation and advantages?Design And Components

The three-wire submersible pump stands out with its unique design. It includes three power conductors and a ground wire. The extra wire is used for the control box, which houses the starting capacitor. This setup allows the pump to start more efficiently. The control box also contains relay and overload protection components, ensuring the pump operates safely. Think of the control box as a brain that communicates with the pump, making decisions on when to start or stop. This added layer of intelligence can extend the lifespan of the pump.Installation Process

Installing a three-wire submersible pump can be a bit more complex than its two-wire counterpart. You need to connect the control box to the pump, which requires additional wiring. Make sure to follow the manufacturer’s instructions closely. Proper installation is crucial for optimal performance and safety. A friend once shared how he mistakenly connected wires incorrectly, leading to a malfunction. Double-checking connections can save you a headache later.Advantages

Three-wire submersible pumps offer several advantages. The control box provides better motor protection, thanks to its overload protection feature. Having a control box means easier troubleshooting. You can pinpoint issues without pulling the pump from the well. The starting capacitor in the control box also helps the pump start smoothly, reducing wear and tear. This can be particularly beneficial if your area experiences frequent power fluctuations.Disadvantages

Despite their benefits, three-wire submersible pumps come with their drawbacks. The additional control box can be costly, and installation requires more time and expertise. There’s also the aspect of maintenance. The control box adds another component that might need attention over time. Consider whether you have the patience and resources to manage these extra complexities. Would the long-term benefits outweigh the initial investment for you? In navigating these choices, remember that every setup offers unique insights. Whether you’re drawn to the simplicity of a two-wire or the intelligence of a three-wire, understanding these pumps helps in making informed decisions.Comparative Analysis

Choosing between two-wire and three-wire submersible pumps can be confusing. Both types serve unique purposes. Understanding their differences helps make informed decisions.

Performance

Two-wire pumps have built-in controls. This makes them easy to install. They often provide reliable performance. Three-wire pumps use external control boxes. These can adjust settings more precisely. Professionals often prefer them for tailored operations.

Cost Implications

Two-wire pumps usually cost less upfront. They require fewer parts for installation. This makes them budget-friendly for many users. Three-wire pumps might have higher initial costs. Their external controls can add to expenses. Long-term savings are possible due to efficient operations.

Maintenance Requirements

Two-wire systems are simpler. This leads to less maintenance over time. Their design reduces the risk of failure. Three-wire pumps need regular checks. Their external controls require careful monitoring. Maintenance can be more demanding.

Safety Considerations

Two-wire pumps integrate safety features internally. This reduces installation errors. It minimizes potential risks during operations. Three-wire pumps rely on external safety controls. Proper installation is crucial. Missteps can lead to safety hazards.

Choosing The Right Pump

Choosing the right pump is crucial for efficient water management. Two wire and three wire submersible pumps offer different benefits. The choice depends on several factors. These include application needs, environmental factors, and budget constraints.

Application Needs

Understanding where the pump is used is essential. Two wire pumps are simpler and easier to install. They are suitable for residential and small-scale applications. Three wire pumps offer more control and flexibility. They are ideal for larger systems and commercial use. Assess your needs before deciding.

Environmental Factors

Consider the surroundings where the pump operates. Two wire pumps work well in clean water environments. They are less suited for areas with debris or minerals. Three wire pumps handle harsher conditions better. They are built to withstand challenging environments. Analyze the environmental factors carefully.

Budget Constraints

Budget plays a significant role in pump selection. Two wire pumps are generally less expensive. They are cost-effective for smaller budgets. Three wire pumps require a larger investment. They offer more features and benefits. Evaluate your financial limits before making a choice.

Installation Tips

Choosing between two-wire and three-wire submersible pumps depends on your installation needs. Two-wire pumps have fewer electrical connections, making them simpler to install. Three-wire pumps offer more control and flexibility but require an additional control box. Consider your specific requirements and expertise before deciding.

Installing a submersible pump can seem daunting, whether you’re dealing with a two-wire or a three-wire system. However, with the right guidance and preparation, you can achieve a smooth installation process. Understanding the nuances of each type is crucial, as it impacts the steps and tools needed. Let’s dive into some essential installation tips that will make your setup easier and more efficient.Pre-installation Checks

Before you start, ensure you have all the necessary components. Check the pump model and specifications, confirming if it’s a two-wire or three-wire. Inspect the well dimensions to ensure compatibility with the pump. Verify that the power supply matches the pump’s requirements, and gather the necessary tools, such as pliers and a voltage tester. Ensuring everything is in order can prevent interruptions. Consider this: How much time and energy could you save by avoiding a mid-process trip to the hardware store?Step-by-step Guide

1. Turn Off Power: Safety first—ensure the power supply is off to prevent accidents. 2. Prepare the Pump: Attach the pipe securely to the pump, ensuring a watertight fit. Use pipe tape where necessary to prevent leaks. 3. Electrical Connections: For a two-wire pump, connect the wires directly to the control box. With a three-wire pump, ensure each wire matches the designated terminal in the control box. 4. Lower the Pump: Carefully lower the pump into the well. Use a safety rope to support the pump’s weight and prevent accidental dropping. 5. Secure Connections: Once in place, secure all electrical connections. Double-check for any loose or exposed wires. 6. Power On and Test: Restore power and test the pump. Listen for unusual noises and check for consistent water flow. Each step is designed to keep the process organized and efficient. Have you considered how following a structured plan could minimize errors?Common Mistakes

Avoid rushing the installation. Hastiness can lead to overlooked steps, resulting in malfunction or damage. One common error is misconnecting wires, especially in three-wire systems. Double-check the wiring diagram to prevent this. Failing to secure the pump properly can cause it to shift or become damaged. Ensure all fittings are tight and the pump is stable before proceeding. Have you ever thought about how small oversights can lead to significant issues later on? Taking your time now could save you from future headaches. By paying attention to these details, you can ensure a successful and long-lasting installation of your submersible pump.

Credit: support.boshart.com

Troubleshooting

Troubleshooting submersible pumps can save time and money. Understanding the differences between two-wire and three-wire systems helps identify problems. Both systems have unique challenges. Addressing these issues efficiently ensures pump longevity and reliability.

Common Issues

Two-wire pumps often face electrical problems. Motor failures are frequent. In contrast, three-wire pumps may have control box issues. Wiring problems can arise in both systems. Identifying the type of pump helps pinpoint potential issues.

Diagnostic Techniques

Testing voltage is crucial. Use a multimeter to check electrical flow. Inspecting connections helps find loose wires. Examine the control box in three-wire systems. Listening to the pump can reveal unusual noises.

Solutions And Repairs

Replace faulty wires to resolve electrical issues. Tighten any loose connections. In three-wire pumps, check the control box for damage. Swap out defective parts with new ones. Consulting a professional can prevent further damage.

Credit: www.waterpumpsdirect.com

Frequently Asked Questions

What Is The Difference Between Two And Three Wire Pumps?

Two-wire pumps have built-in controls. Three-wire pumps need an external control box. Easier maintenance with two-wire.

Why Choose A Two-wire Submersible Pump?

Two-wire pumps are simpler. They have fewer components. Easier to install. Less maintenance required.

Are Three-wire Pumps More Reliable?

Three-wire pumps offer more control. Easier to troubleshoot. Can be more reliable in the long run.

Which Pump Is Easier To Install?

Two-wire pumps are easier. No control box needed. Fewer connections to make.

Do Two-wire Pumps Cost Less?

Yes, generally. Fewer parts mean lower initial costs. But, long-term costs depend on usage and maintenance.

Conclusion

Choosing between two wire and three wire pumps can be tricky. Both have unique benefits. Two wire pumps are simpler and easier to install. Ideal for straightforward tasks. Three wire pumps offer more control and flexibility. Better for complex systems.

Consider your specific needs and budget carefully. Ask an expert if unsure. Understanding these differences can guide you to the right decision. Whether for a home or farm, picking the right pump ensures efficiency. Save energy and reduce maintenance costs.

Make an informed choice for a reliable water system.