Imagine you’re standing in your garage, ready to tackle that home improvement project you’ve been dreaming about. You’ve got all your tools lined up, but now comes the crucial decision: should you use anchoring cement or anchoring epoxy?

These two materials might seem similar, but they can make a world of difference in your project’s outcome. Choosing the right one could mean the difference between a structure that’s stable for years and one that needs frequent repairs. You want your work to last, to be strong, reliable, and impressive.

But how do you decide which is better for your needs? This article is your guide to understanding the strengths and weaknesses of anchoring cement versus anchoring epoxy, helping you make an informed choice that will bring peace of mind and satisfaction. Let’s dive deeper into the details that will empower you to make the best decision for your project.

Credit: www.homedepot.com

Anchoring Cement Basics

Anchoring cement is a vital component in construction and DIY projects. It offers strong support for structures by securely fixing them into place. Understanding its basics can help you choose the right material for your next project.

Composition And Properties

Anchoring cement is primarily made from a mixture of portland cement and additives. These additives enhance its strength and adhesion properties. The cement typically sets quickly, which is ideal for fast-paced projects.

Its ability to expand slightly upon setting provides a tight grip on the anchor. This ensures stability and support for the structure. The durability of anchoring cement makes it suitable for projects exposed to varying weather conditions.

Common Applications

Anchoring cement is commonly used in securing bolts, rods, and other fixtures. It’s perfect for applications where you need to fasten items to concrete surfaces. Think about securing a railing or installing a heavy-duty shelf.

It’s also used in tasks such as setting poles or posts in concrete. This is crucial in outdoor projects like fencing or signage installation. Have you ever wondered how street signs stay upright amidst strong winds? Anchoring cement is often the answer.

When considering your next project, ask yourself: Is anchoring cement the right fit for your needs? Its quick-setting nature and adaptability to various conditions make it a reliable choice for many. But ensure you assess the specific requirements of your task to make the best decision.

Anchoring Epoxy Essentials

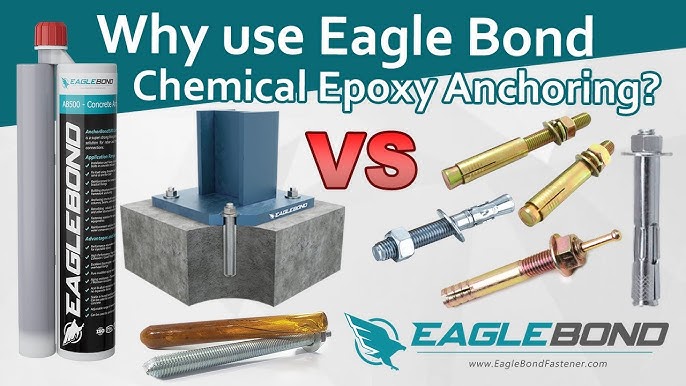

In the world of construction and DIY projects, the choice between anchoring cement and anchoring epoxy can significantly impact the durability and strength of your installations. Anchoring epoxy, in particular, stands out due to its versatile applications and robust chemical properties. But what makes it so essential? Let’s dive into the details.

Chemical Structure And Benefits

Anchoring epoxy is composed of a two-part system: resin and hardener. When mixed, these components create a strong adhesive bond. This chemical structure gives anchoring epoxy its unique ability to withstand heavy loads and resist environmental wear.

One of the greatest benefits is its adaptability. Whether you’re dealing with concrete, wood, or metal, anchoring epoxy provides a reliable bond. Imagine working on a home project where weather conditions are unpredictable. Epoxy’s resistance to moisture and temperature changes ensures your work remains secure.

Typical Uses

Anchoring epoxy is commonly used in scenarios that demand high strength and durability. From securing bolts in concrete to reinforcing structural elements, its applications are vast. Have you ever fixed a loose railing and worried it might give way? Epoxy can eliminate such concerns with its steadfast grip.

It’s also a favorite among DIY enthusiasts for creating custom art pieces or furniture. You might be surprised to find how epoxy can enhance your creativity. By anchoring various elements securely, you can focus on design without compromising stability.

Thinking about your next project? Consider how anchoring epoxy could make it last longer and perform better. What features would you prioritize in your materials to ensure the best outcome?

Performance Comparison

Choosing between anchoring cement and anchoring epoxy can be tricky. Each offers unique performance benefits. Understanding their strengths can guide your decision. Let’s explore their differences in strength, durability, and resistance to environmental factors.

Strength And Durability

Anchoring cement is known for its strong hold. It supports heavy loads effectively. This makes it ideal for structural applications. Its durability ensures long-term reliability. Anchoring epoxy also offers remarkable strength. It bonds tightly to surfaces. This creates a secure and lasting hold. Epoxy is often preferred for its flexibility. It absorbs vibrations better than cement.

Resistance To Environmental Factors

Anchoring cement withstands harsh weather conditions. It’s resistant to moisture and temperature changes. This makes it suitable for outdoor installations. Epoxy, on the other hand, excels in chemical resistance. It resists oils, acids, and other corrosive elements. This makes epoxy perfect for industrial use. Cement can be prone to cracking in extreme conditions. Epoxy maintains its integrity even in challenging environments.

Installation Process

The installation process for anchoring cement and anchoring epoxy differs. Both materials offer unique benefits. Understanding these differences is crucial for a successful application. Let’s explore the preparation and tools required, followed by the steps for application.

Preparation And Tools Required

Preparing the surface is vital for a strong bond. Clean the area thoroughly. Remove dust and debris. For anchoring cement, gather a mixing tool, bucket, and trowel. Anchoring epoxy requires a caulking gun, mixing nozzle, and safety gloves. Ensure all tools are within reach before starting. This saves time and ensures efficiency.

Steps For Application

Follow specific steps for each material. For anchoring cement, mix the cement with water. Achieve the right consistency. Apply the mixture using a trowel. Fill the hole completely. For anchoring epoxy, insert the cartridge into the caulking gun. Attach the mixing nozzle. Squeeze the trigger to mix the epoxy. Fill the hole with the mixed epoxy. Allow it to cure as per instructions. Monitor the curing process. Ensure optimal strength and durability.

Cost Analysis

Choosing between anchoring cement and anchoring epoxy involves considering costs. Both materials offer unique benefits and limitations. A detailed cost analysis helps in making an informed decision. Let’s dive into the specifics.

Material Costs

Anchoring cement is generally less expensive upfront. It’s a straightforward option for many projects. The cost varies based on brand and quantity. On the other hand, anchoring epoxy often carries a higher price tag. This is due to its chemical properties and strength. For long-term projects, the initial cost of epoxy may be justified.

Labor And Time Considerations

Labor costs differ between the two materials. Anchoring cement usually requires more preparation and curing time. This can increase labor costs significantly. Epoxy, in contrast, often needs less time to set. This can reduce labor expenses. Faster setting times of epoxy can lead to quicker project completion. This may be a crucial factor in time-sensitive projects. Choosing the right material can impact the overall budget.

Credit: www.youtube.com

Environmental Impact

Anchoring cement and anchoring epoxy differ significantly in their environmental impacts. Cement production emits high levels of CO2, contributing to global warming. Conversely, anchoring epoxy, made from resins, can release harmful chemicals into the environment during use and disposal. Each material presents unique ecological challenges.

When considering the environmental impact of construction materials, it’s crucial to compare anchoring cement and anchoring epoxy. Both materials serve similar purposes but have distinct effects on our planet. Understanding these differences can guide you in making more eco-friendly decisions for your projects.Eco-friendliness

Anchoring cement is often lauded for its natural composition. Made primarily from limestone and clay, it has a lower carbon footprint compared to synthetic alternatives. However, the production of cement is energy-intensive, leading to significant carbon dioxide emissions. Anchoring epoxy, on the other hand, is a synthetic material. Its production involves petrochemical processes, which can have a substantial environmental impact. Despite this, some manufacturers are making strides to create more sustainable epoxy options. Have you considered how the production processes of these materials affect the environment?Disposal And Recycling

Disposing of leftover anchoring cement is relatively straightforward. It can often be recycled or used as a base for new construction projects. This ability to be repurposed reduces waste and promotes a circular economy. Conversely, anchoring epoxy presents more challenges when it comes to disposal. Being a synthetic product, it does not biodegrade easily and can contribute to landfill waste. However, some companies are developing recycling programs to manage epoxy waste responsibly. Could these initiatives influence your choice between cement and epoxy? In making decisions about materials, it’s vital to weigh their environmental impact. Reflecting on these factors can help you contribute to a more sustainable future in your projects.Choosing The Right Material

Choosing between anchoring cement and anchoring epoxy can be tricky. Both materials have unique benefits. It’s important to understand your project’s needs. This helps in making an informed decision. The right choice ensures stability and durability.

Project Requirements

Consider the nature of your project. What type of load will it bear? Anchoring cement is suitable for lighter loads. It is often used for non-critical structures. For heavy-duty projects, anchoring epoxy is preferable. It handles higher stress and weight. Also, think about the environmental conditions. High moisture levels affect cement more than epoxy.

Expert Recommendations

Experts suggest consulting with a professional. This ensures you choose the best material. For quick installations, anchoring cement is ideal. It sets faster and is easier to use. Epoxy is recommended for precision work. It provides a stronger bond and longer-lasting results. Professionals often favor epoxy for critical applications. Always consider expert opinions before making a decision.

Credit: m.youtube.com

Frequently Asked Questions

What Is Anchoring Cement Used For?

Anchoring cement is used for securing bolts, rods, and fixtures in concrete. It provides strong, reliable support.

How Does Anchoring Epoxy Work?

Anchoring epoxy bonds materials together. It fills gaps and provides a strong, durable hold, even in harsh conditions.

Which Is Stronger: Anchoring Cement Or Epoxy?

Anchoring epoxy is generally stronger. It offers superior bonding and flexibility compared to cement, especially in dynamic environments.

Is Anchoring Cement Better For Outdoor Use?

Yes, anchoring cement is ideal for outdoor projects. It withstands weather changes and provides stable support.

Can I Use Anchoring Epoxy On Wet Surfaces?

Yes, many anchoring epoxies are designed for wet conditions. They bond well even on damp surfaces.

Conclusion

Choosing between anchoring cement and epoxy depends on your project needs. Cement offers strong bonding for heavy-duty tasks. It’s ideal for anchoring large structures. Epoxy provides versatility and quick setting times. It suits lighter applications and precise work. Consider the environment, too.

Cement performs well outdoors, resisting weather effects. Epoxy excels indoors, where moisture is controlled. Evaluate your specific requirements. Think about load, location, and material compatibility. Both materials have unique strengths. Make an informed decision for the best results. Your project will thank you for it.