When it comes to mixing, blending, or stirring, the choice between an agitator and an impeller can make all the difference in your process efficiency. But how do you know which one is right for your specific needs?

Whether you’re in the food industry, pharmaceuticals, or any other sector that relies on mixing, understanding the nuances between these two tools is crucial. Imagine optimizing your operations, saving time, and enhancing product quality simply by selecting the right equipment.

Intrigued? Let’s dive into the world of agitators and impellers, unraveling their secrets to help you make informed decisions that could transform your business. Prepare to discover insights that could elevate your mixing processes to new heights. Keep reading, because what you’ll learn might just change the way you think about mixing forever.

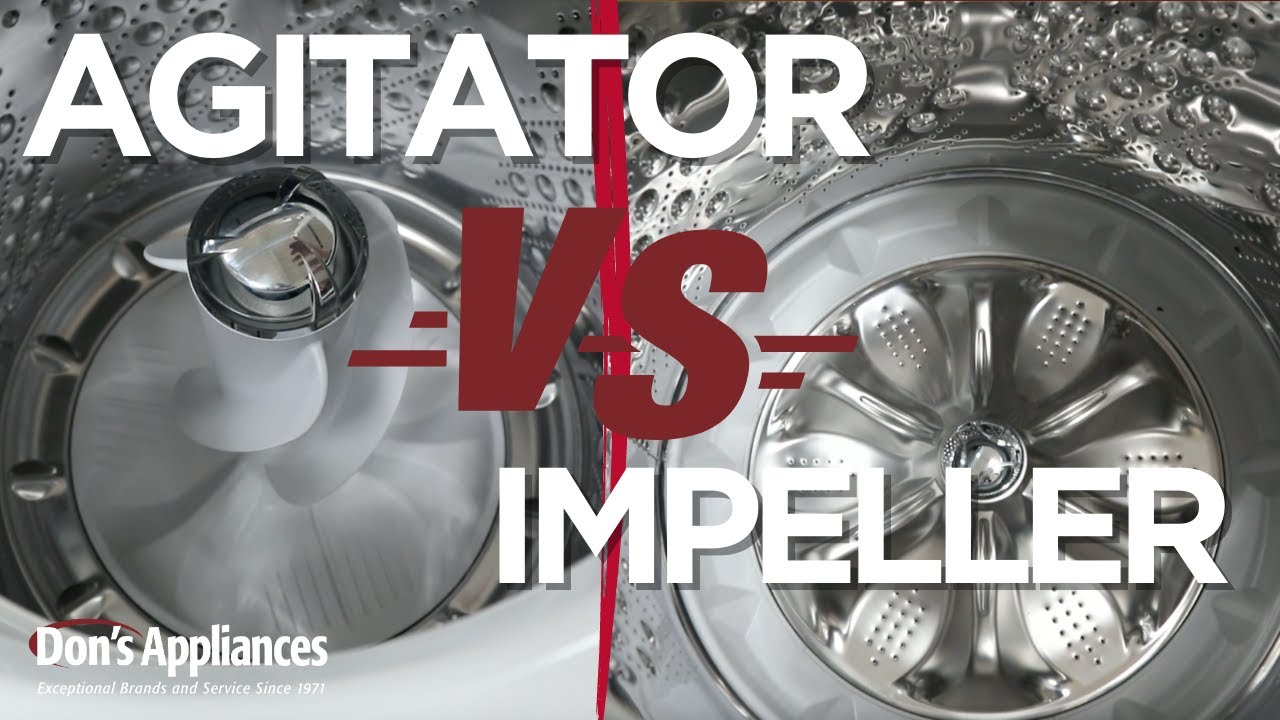

Credit: www.youtube.com

Basics Of Agitators And Impellers

Understanding the basics of agitators and impellers can be a game-changer for anyone interested in mixing technologies. Whether you’re in the food industry or dealing with chemicals, these devices play a crucial role in blending, stirring, and mixing materials effectively. But what exactly sets them apart? Let’s dive into the fundamental differences and functionalities of these essential mixing tools.

Agitators: The Basics

Agitators are devices designed to stir or shake fluids in a container. They are typically used in larger tanks where thorough mixing is required. Imagine you’re trying to mix paint in a gigantic vat; an agitator can ensure that every hue blends perfectly. They work by creating motion in the liquid, ensuring uniformity.

One interesting aspect of agitators is their versatility. You can use them for mixing liquids, suspending solids, or even blending gases. Their adaptability makes them a favorite in industries like pharmaceuticals and food processing. Have you ever wondered how your favorite soda gets its fizzy consistency? Agitators play a pivotal role in that process.

Impellers: The Basics

Impellers, on the other hand, are a type of rotor used to increase the pressure and flow of a fluid. They are usually found in pumps, and their primary role is to move fluids efficiently. Picture the propeller of a boat; an impeller works similarly to push fluid forward.

In terms of design, impellers are more compact compared to agitators. They’re ideal for systems where space is limited but efficient fluid movement is crucial. Think about the engine cooling system in your car; impellers help circulate coolant to keep your engine from overheating.

Key Differences

So, why choose one over the other? Agitators are perfect for mixing processes where uniformity is key. They ensure that every component of your mixture is evenly distributed. Impellers excel in applications where fluid movement is the priority. They are all about generating flow and increasing pressure.

Imagine you’re baking a cake; agitators would be your whisk, ensuring all ingredients blend evenly. Impellers would be the fan in your oven, making sure heat circulates to bake your cake perfectly. Different tasks, different tools.

Choosing The Right Tool For Your Needs

When faced with choosing between an agitator and an impeller, consider your specific requirements. Do you need thorough mixing or efficient fluid movement? The answer will guide your choice.

Have you ever had a project where the tools seemed to make all the difference? Selecting the right mixing device can be as crucial as choosing the right paintbrush for an artist. Ask yourself: What do you need to achieve with your mixture? The solution lies in your unique needs.

Design And Structure

In industrial mixing, the design and structure of equipment matter. Two common types are agitators and impellers. They have unique designs and structures. Understanding these differences helps in choosing the right tool for the job.

Agitator Design

Agitators are generally larger and more complex. They mix substances in large tanks or vessels. Agitators often have paddles or blades. These components move slowly. The slow movement ensures thorough mixing. Agitators are versatile. They work well with both liquids and solids. They are often used in chemical and food industries. Their design allows them to handle varying viscosities.

Impeller Structure

Impellers are smaller and more compact. They are usually found in pumps and blenders. Impellers have blades or vanes. These parts rotate at high speeds. The high speed creates a strong flow. This flow moves liquids quickly and efficiently. Impellers are ideal for fluid mixing. They are often used in water treatment and chemical processing. Their structure is simple yet effective.

Functionality And Operation

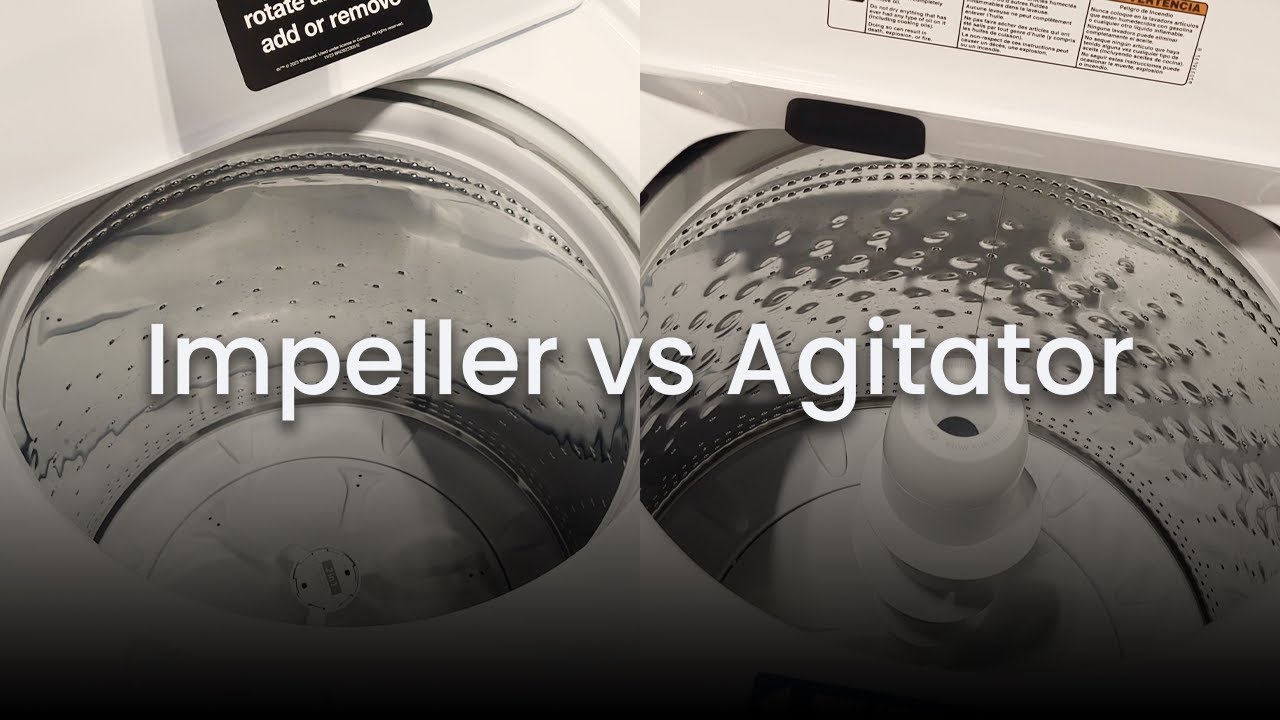

Agitators and impellers are both used in washing machines to clean clothes effectively. Agitators move clothes through the water using a central post with paddles, enhancing cleaning power for heavily soiled items. Impellers use a low-profile cone or disc that gently moves clothes, ideal for delicate fabrics and energy efficiency.

Understanding the functionality and operation of agitators and impellers is crucial for anyone involved in the processing or mixing industry. Each plays a unique role in ensuring efficient mixing, but their mechanisms differ. Have you ever wondered why a certain mixer works better in one situation than another? Let’s explore how these two components operate and contribute to effective mixing.How Agitators Work

Agitators are designed to mix liquids and promote homogeneity. They use a simple mechanism—a rotating blade that stirs the liquid. The blade’s movement creates a flow pattern that blends ingredients consistently. Imagine you’re mixing paint in a can. An agitator would be like a stick stirring the paint to ensure the color is even throughout. This is similar to how agitators function in large-scale industrial settings. They keep the liquid moving, preventing sedimentation and separation. Agitators are ideal for processes requiring gentle mixing. They ensure each ingredient is uniformly distributed without causing excessive shearing or breaking down the material.Impeller Mechanisms

Impellers, on the other hand, use a more dynamic approach. They consist of a rotor that spins at high speeds, creating a centrifugal force. This force moves the fluid from the center towards the edges of the container. Picture a blender in your kitchen. The blades spin rapidly, pulling ingredients down and pushing them outwards, creating a vortex. That’s how impellers operate, generating a robust flow that facilitates thorough mixing. Impellers are best suited for tasks requiring intense mixing. They work efficiently in processes where components need to be broken down quickly and evenly. Choosing between an agitator and an impeller depends on your specific needs. Do you need gentle blending or vigorous mixing? Understanding their operation helps you make informed decisions that enhance productivity and product quality.Performance Factors

Understanding the performance factors of agitators and impellers is essential. These factors determine how efficient and adaptable each option is. This comparison helps industries choose the right equipment for their needs.

Mixing Efficiency

Mixing efficiency is a critical element in processing. Agitators provide uniform mixing for various substances. They work well with thick liquids and solids. Impellers are better for quick blending. They excel in mixing liquids with different densities. Impellers maintain consistent flow patterns. This ensures thorough mixing.

Energy Consumption

Energy consumption impacts operational costs. Agitators usually need more power. They work continuously to mix dense materials. Impellers consume less energy. Their design allows smooth operation. Impellers use energy efficiently, reducing costs.

Versatility And Adaptability

Versatility and adaptability are key for diverse applications. Agitators adapt to various substances. They handle tasks in different industries. Impellers offer great flexibility. They can be used in different mixing scenarios. This makes them suitable for many processes.

Applications In Industry

Agitators and impellers are vital in mixing processes within industries. Agitators mix liquids, ensuring uniformity in chemical reactions. Impellers, often part of pumps, move fluids efficiently, enhancing flow and reducing energy consumption. Both play crucial roles in optimizing industrial operations, ensuring productivity and efficiency.

In the world of industrial machinery, the choice between an agitator and an impeller can significantly impact the efficiency of your operations. Understanding their applications can guide you in making the best decision for your specific needs. These devices are crucial in various industries, each offering unique benefits.Common Uses Of Agitators

Agitators are often used in industries where mixing is critical. You’ll find them in the food and beverage sector, where uniformity in mixing ingredients is key. They are also prevalent in chemical plants, where precise blending of substances is essential. In the paint and coatings industry, agitators ensure that pigments and solvents mix thoroughly. They help maintain consistency and prevent separation over time. If you’ve ever painted a room, you know how frustrating it can be if the paint isn’t mixed well.Impeller Applications

Impellers shine in scenarios requiring efficient fluid movement. The pharmaceutical industry relies on them for processes like dissolving, where quick and efficient mixing is necessary. Their design allows for rapid liquid movement, making them ideal for high-speed mixing tasks. In wastewater treatment plants, impellers play a pivotal role. They help in aerating the water, ensuring the right balance of oxygen for microbial activity. This process is vital for breaking down organic matter and maintaining water quality. Have you ever noticed the whirring sound of a blender? That’s an impeller at work, quickly blending smoothies to perfection. It’s a small-scale application, but the principle remains the same in large-scale industries. Choosing between an agitator and an impeller might seem daunting. Yet, knowing their applications can help you understand which suits your industrial needs. What are your mixing challenges, and how might these devices offer a solution?Cost Considerations

Cost is crucial in choosing between agitators and impellers. Agitators often have higher upfront costs due to complex designs. Impellers may offer lower initial costs, appealing for budget-conscious projects.

When deciding between an agitator and an impeller for your washing machine, cost is a significant factor that can influence your choice. While both options have their own benefits, understanding the financial implications can help you make an informed decision. Let’s explore the cost considerations, breaking them down into initial investment and ongoing maintenance and operating costs.Initial Investment

Purchasing a washing machine with an agitator often comes with a lower initial price tag. These models are typically more budget-friendly, making them an attractive option if you’re keeping a close eye on your spending. In contrast, impeller machines may require a higher upfront investment. The advanced technology and design contribute to the increased cost. However, it’s worth asking yourself if the potential benefits and features justify the price difference.Maintenance And Operating Costs

Maintenance costs can vary significantly between agitator and impeller washing machines. Agitators, with their more traditional design, might require more frequent repairs. This could lead to higher long-term expenses. Impeller machines, on the other hand, often boast more efficient operation. They tend to use less water and energy, which can reduce your utility bills. Could this efficiency eventually offset the initial higher cost? It’s a question worth pondering. Consider your own experiences with appliance maintenance. Have you found yourself investing more in repairs over time? Reflecting on these costs can provide valuable insights into the true cost of ownership. In conclusion, weighing the initial investment against the ongoing expenses is crucial. By understanding both aspects, you can choose a washing machine that aligns with your budget and lifestyle. What matters most to you: saving upfront or investing in long-term efficiency?Advantages And Disadvantages

Choosing between agitators and impellers can be tricky. Each has its own set of advantages and disadvantages. Understanding these can help make an informed decision.

Pros And Cons Of Agitators

Agitators are powerful and efficient. They mix materials thoroughly. They work well with large volumes. Agitators are great for heavy-duty tasks. They handle viscous liquids easily. Agitators can be noisy, though. Maintenance can be complex. They might consume more energy. Agitators take up more space. They are not ideal for delicate substances.

Pros And Cons Of Impellers

Impellers are compact and quiet. They are energy-efficient. Impellers work well with delicate substances. They are easy to maintain. Installation is simple with impellers. They might not mix thick liquids well. Impellers are less effective with large volumes. They may require frequent cleaning. Impellers can wear out quickly. Their mixing is sometimes less thorough.

Credit: www.youtube.com

Choosing The Right Option

Selecting between agitators and impellers requires understanding their unique functions. Agitators mix substances efficiently, ideal for thick mixtures. Impellers excel in moving fluids, perfect for liquid blending. Each option serves distinct purposes, ensuring optimal performance based on specific needs.

Choosing the right mixing equipment for your industrial needs can be a daunting task. You might be wondering whether an agitator or an impeller is the better option. Each has its own strengths, and the choice largely depends on the specific requirements of your industry.Factors To Consider

First, think about the viscosity of the materials you’ll be working with. Agitators are typically better suited for high-viscosity applications, like mixing dough or heavy creams. Impellers, on the other hand, excel in low-viscosity environments, such as mixing liquids or thin slurries. Consider the mixing speed and shear required. Agitators operate at lower speeds, which is ideal for gentle mixing. Impellers can work at higher speeds, making them perfect for applications needing intense mixing. Space constraints are also crucial. Agitators often require more space and may not fit into smaller tanks. Impellers are generally more compact, offering a space-saving solution.Industry-specific Needs

Every industry has its unique challenges and requirements. In the food and beverage industry, maintaining product consistency is vital. Agitators are often preferred for their ability to mix ingredients uniformly without compromising texture. In the chemical industry, precise mixing is essential for reaction control. Here, impellers are favored for their capability to quickly blend reactants, ensuring efficient chemical reactions. Pharmaceutical companies require sanitation and precision. Impellers, with their streamlined design, are easier to clean and maintain, making them a popular choice in this field. Have you ever considered how your choice impacts your production efficiency? Selecting the right equipment not only affects the quality of your product but can also save time and reduce costs. Make an informed decision by weighing these factors and industry needs carefully.

Credit: www.homedepot.com

Frequently Asked Questions

What Is The Main Difference Between Agitators And Impellers?

Agitators mix substances by moving them around. Impellers push liquids to create flow. Different purposes.

Which Is Better For Industrial Mixing?

It depends on the application. Agitators suit thicker materials. Impellers work well with fluids.

How Do Agitators And Impellers Affect Energy Use?

Impellers are typically more energy-efficient. They require less power to move fluids compared to agitators.

Are Agitators And Impellers Used In Home Appliances?

Yes. Washing machines use agitators. Dishwashers often have impellers. Each suits different washing needs.

Can Agitators And Impellers Be Used Together?

Yes, sometimes combined for better results. Each enhances the other’s strengths in mixing processes.

Conclusion

Choosing between an agitator and an impeller depends on your needs. Agitators mix liquids well, making them ideal for thicker materials. Impellers suit processes that need rapid mixing and less shear. Both have unique benefits for different tasks. Consider the material type and process requirements.

Evaluating these factors helps in making a sound choice. Each option offers distinct advantages. Think about your specific application. This ensures you pick the right equipment. Proper selection leads to efficient operations. Remember, understanding your needs is key. Make an informed decision for optimal performance.