To troubleshoot a White Rodgers gas valve, check for power supply and gas flow issues. Consult the manual for specific guidance.

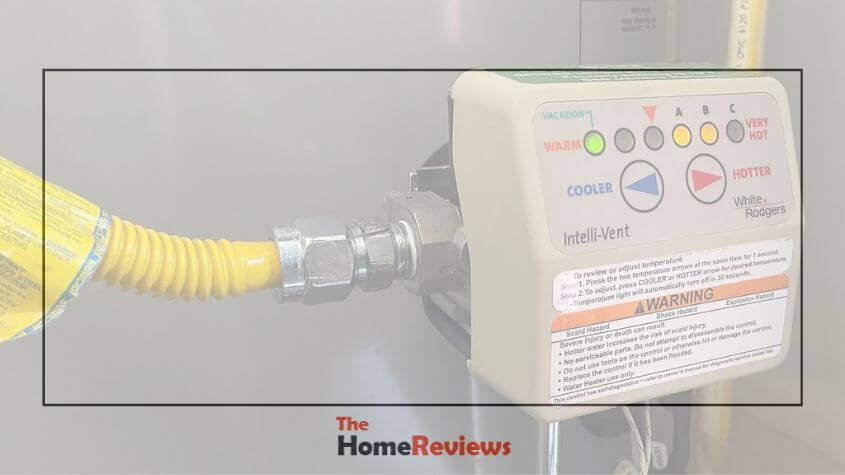

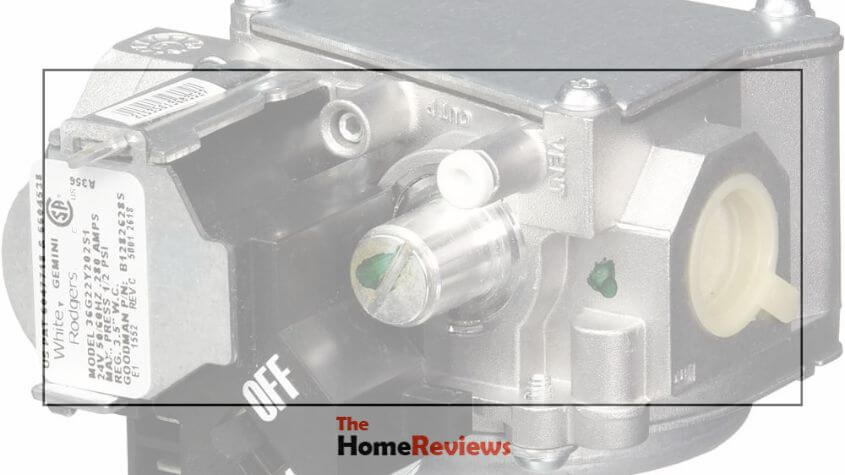

White Rodgers gas valves are essential components of your heating system, regulating the flow of gas to ensure efficient and safe operation. However, like any mechanical device, they can sometimes experience issues that require troubleshooting. If you are facing problems with your White Rodgers gas valve, it is important to address them promptly to prevent any disruptions to your heating system.

In this guide, we will provide you with some common troubleshooting steps to help you diagnose and resolve issues with your White Rodgers gas valve. By following these steps, you can ensure that your heating system continues to operate effectively and efficiently.

Common Gas Valve Problems

When dealing with a gas valve, it’s essential to be aware of common problems that may arise. Identifying these issues can help in troubleshooting and resolving any heating system issues efficiently. Whether you’re facing no heat or intermittent heat problems, understanding the potential causes and solutions is crucial for maintaining a safe and functional gas valve. Let’s delve into the common gas valve problems and how to address them.

No Heat

If your heating system is not producing any heat, it could be due to several reasons. Some common causes of no heat from a gas valve include a malfunctioning thermocouple, a faulty gas valve, or an issue with the thermostat. Insufficient gas supply or a clogged pilot tube may also lead to this problem.

Intermittent Heat

Intermittent heat issues can be frustrating and often stem from irregular gas flow. This problem may arise from a faulty solenoid or a buildup of debris within the gas valve. Additionally, inadequate voltage to the gas valve or a worn-out igniter can cause intermittent heat.

Diagnostic Techniques

When troubleshooting White Rodgers gas valves, utilizing effective diagnostic techniques is crucial. By following a systematic approach, you can accurately pinpoint and resolve issues with the gas valve. Here are the key steps for diagnostic techniques:

Check For Power Supply

- Ensure the power supply to the gas valve is properly connected.

- Check for any tripped circuit breakers or blown fuses affecting the power supply.

Test For Voltage

- Use a multimeter to test the voltage coming into the gas valve.

- Verify that the voltage matches the required specifications for proper operation.

Inspect the ignition system

- Examine the ignition system for any signs of damage or wear.

- Clean the ignition components and ensure they are functioning correctly.

1, Check for Power Supply: Ensure the power supply is connected properly.

2, Test for Voltage: Use a multimeter to check the voltage.

3. Inspect the ignition system: examine and clean the ignition components.

By following these steps, you can effectively troubleshoot White Rodgers gas valves.

Troubleshooting Steps

When it comes to troubleshooting White Rodgers gas valve issues, following a systematic approach can help identify and solve the problem efficiently. The troubleshooting steps outlined below will guide you through the process of diagnosing gas valve problems and resolving them effectively.

Check Gas Supply

Ensure the gas supply is turned on, and check for any obstructions in the gas line.

Inspect Valve Wiring

Examine the wiring connections to the gas valve for any signs of damage or loose connections.

Clean Valve Connections

Clean the valve connections using a soft brush or cloth to remove any dust or debris that may be affecting the valve’s operation.

Replace Faulty Components

If all other troubleshooting steps fail to resolve the issue, consider replacing any faulty components within the gas valve assembly.

Safety Precautions

When troubleshooting White Rodgers gas valves, it’s crucial to adhere to safety precautions to prevent any potential hazards. Here are some essential safety measures to follow before commencing any gas valve troubleshooting.

Shut Off the Gas Supply

Before starting any maintenance or troubleshooting procedures, ensure to shut off the gas supply to the affected area using the gas shut-off valve. This will prevent any accidental gas leaks during the troubleshooting process.

Turn Off Power

In addition to shutting off the gas supply, make sure to turn off the electrical power connected to the gas valve to eliminate the risk of electrical accidents. This step is crucial for ensuring safety during the troubleshooting process.

Wear Protective Gear

It’s essential to wear appropriate protective gear, including gloves and eye protection, to safeguard against any potential hazards during the troubleshooting process. Protective gear helps to ensure personal safety and mitigate the risk of accidents.

By following these safety precautions, you can ensure a safe and secure environment for troubleshooting White Rodgers gas valves, mitigating the risk of accidents and ensuring a smooth troubleshooting process.

When To Call A Professional

While troubleshooting gas valve issues for your White Rodgers system can often be done on your own, there are certain situations where it’s best to leave the job to a professional. Calling a professional service technician can save you both time and potential frustration.

Complex Repairs

If you have already attempted basic troubleshooting steps without success, it may indicate that the issue is more complex than initially thought. Complex repairs often require specialized knowledge and tools to be properly addressed.

If you find yourself stuck or overwhelmed while trying to troubleshoot your White Rodgers gas valve, it’s a clear sign that it’s time to call a professional. They have the experience and expertise to handle complex repairs efficiently and effectively.

Lack Of Technical Knowledge

Gas valves are intricate components comprising various complex mechanisms. Without a solid understanding of how these components work and interact with each other, attempting repairs yourself can be risky. One wrong move could worsen the problem or pose a safety hazard.

If you lack the technical knowledge needed to troubleshoot your White Rodgers gas valve, it’s best not to take any chances. A professional technician possesses the necessary training and expertise to identify and resolve the issue without causing further damage.

Safety Concerns

Gas valves are critical for the safe operation of your heating system. Mishandling or incorrect repairs can lead to gas leaks, fire hazards, or carbon monoxide poisoning. Safety should always be a top priority when dealing with gas appliances.

If you suspect a safety issue with your White Rodgers gas valve or if you smell gas, immediately evacuate the premises and contact a professional technician for assistance. They have the knowledge and equipment to safely diagnose and fix any potential safety concerns.

Frequently Asked Questions

How to Troubleshoot a White Rodgers Gas Valve?

Troubleshoot a White Rodgers gas valve by checking for gas supply, power supply, and valve operation.

Why Is My White Rodgers Gas Valve Not Working?

Your White Rodgers gas valve might not be working due to a faulty electrical connection or a gas supply issue.

What Are the Common Signs of a Faulty White Rodgers Gas Valve?

Common signs of a faulty White Rodgers gas valve include no heat, inconsistent heat, or a malfunctioning pilot light.

Can I Fix a White Rodgers Gas Valve Myself?

It is recommended to consult a professional technician for repairing a White Rodgers gas valve to ensure safety and proper functioning.

How Much Does It Cost To Replace A White Rodgers Gas Valve?

The cost of replacing a White Rodgers gas valve can vary depending on the model and professional service fees.

Conclusion

In troubleshooting White Rodgers gas valves, regular maintenance and thorough inspection are crucial. By following the steps outlined in this guide, you can quickly identify and resolve common issues. Keep in mind that consulting a professional technician is advisable for complex problems.

With a proactive approach, you can ensure the safe and efficient functioning of your gas valve system.