PVC primer is an essential component in creating strong and reliable joints when working with PVC pipes. While it may be possible to create joints without using primer, the primer ensures that the joints are as strong as possible, especially when dealing with liquid media passing through them.

It is recommended to use primer on any joints that will have liquid media flowing through them. Additionally, the primer should still be wet when applying the cement to ensure optimal results. The primer acts as a cleaner, removing grime and softening the surface for proper adhesion of the PVC cement.

Without primer, the glue would essentially just act as a gap filler.

The Essential Role Of Pvc Primer

PVC primer plays a crucial role in the solvent cementing process of PVC pipes. It prepares the surface, allowing for a strong and durable bond between the pipes and fittings. Without the use of PVC primer, the joint may not achieve the intended strength and could be prone to leakage or failure over time.

Chemical Composition Changes

When PVC primer is applied to the PVC pipe and fittings, it initiates a chemical reaction that alters the surface of the material. This alteration is essential for the solvent cement to effectively bond the pieces together. The primer softens the PVC, creating a secure foundation for the subsequent application of the solvent cement.

Surface Preparation For Solvent Cement

PVC primer not only changes the chemical composition of the PVC surface but also serves as a cleaning agent. It removes dirt, grime, and any contaminants that could inhibit the bonding process. The softened surface, facilitated by the primer, ensures that the solvent cement can effectively penetrate and fuse the PVC components, creating a strong and reliable joint.

Primer Vs. Cement: The Dynamic Duo

When it comes to joining PVC pipes, the primer and cement work together as a dynamic duo, each playing a crucial role in creating strong, reliable joints. Let’s delve into the intricacies of this essential partnership and understand why both are critical for achieving durable connections.

The Primer-cement Interaction

The interaction between PVC primer and cement is vital for creating a secure bond between PVC pipes.

The primer prepares the surface of the PVC pipe, making it more porous and receptive to the cement.

This enhanced surface allows the cement to penetrate and bond effectively with the pipe, ensuring a strong and durable joint.

Why Both Are Critical For Strong Joints

Using both primer and cement is essential for ensuring the longevity and reliability of PVC pipe joints.

The primer not only cleans the surface but also softens it, allowing the cement to create a solvent weld that fuses the PVC pieces together.

By working in tandem, the primer and cement ensure that the joints can withstand the pressures and demands placed upon them, providing a leak-free and durable piping system.

Application Techniques For Pvc Primer

When it comes to joining PVC pipes, using a PVC primer is an essential step in the process. PVC primer helps prepare the surface of the pipes for the glue, ensuring a strong and durable bond. In this section, we will discuss the step-by-step application process for PVC primer and highlight common mistakes to avoid.

Step-by-step Primer Application

- Start with Clean Material: Before applying the primer, make sure the surfaces of the PVC pipes are clean and free from dirt, debris, and any old adhesive residue. This will ensure proper adhesion.

- Cut PVC Pipe Squarely: Ensure that the ends of the pipes are cut squarely to create a flush joint.

- Debur & Bevel: Use a deburring tool to remove any sharp edges or burrs from the cut ends of the pipes. Additionally, beveling the edges slightly can help improve the adhesive bond.

- Proper Primer Application: Apply a generous amount of PVC primer to both the outside of the pipe and the inside of the fitting. Use a brush or applicator to evenly coat the surfaces.

- PVC Glue Application: After applying the primer, immediately apply PVC glue to the primed surfaces. Be sure to apply the glue evenly and avoid excessive amounts.

- Wipe Off Excess Glue & Primer: Once the pipes are joined, use a clean cloth or rag to wipe off any excess glue or primer. This will ensure a clean and neat finish.

Common Mistakes To Avoid

- Not Cleaning the Surfaces Properly: Failing to clean the surfaces of the PVC pipes can lead to poor adhesion and weak joints. Always take the time to thoroughly clean the pipes before applying the primer.

- Insufficient Primer Application: Applying too little primer or unevenly coating the surfaces can result in a weaker bond. It is important to apply a sufficient amount of primer and ensure even coverage.

- Delaying Glue Application: Once the primer is applied, it is crucial to immediately apply the PVC glue. Delaying the glue application can cause the primer to dry, resulting in a weaker bond.

- Using Excessive Glue: Applying too much PVC glue can lead to messy joints and may weaken the bond. It is important to use the right amount of glue as recommended by the manufacturer.

- Skipping the Wiping Step: Neglecting to wipe off excess glue and primer can result in a messy appearance and may compromise the integrity of the joint. Always take the time to clean up any excess adhesive.

By following these step-by-step primer application techniques and avoiding common mistakes, you can ensure strong and durable joints when working with PVC pipes. Remember, proper application of PVC primer is essential for achieving reliable and long-lasting connections.

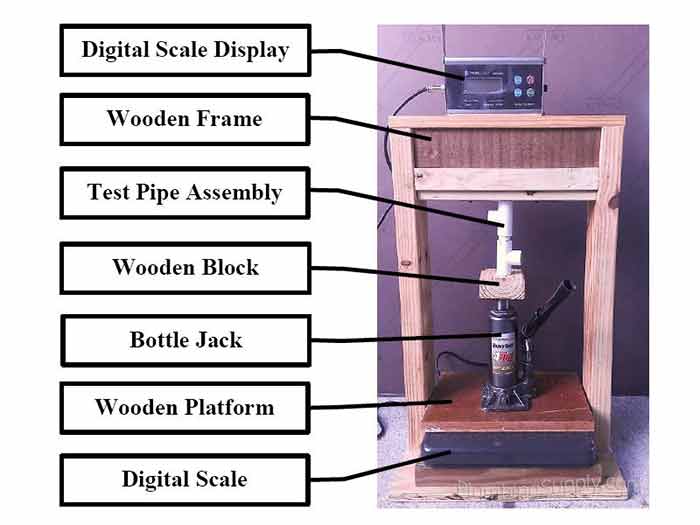

Credit: www.commercial-industrial-supply.com

The Chemistry Behind Pvc Primer

PVC primer plays a crucial role in ensuring strong joints for PVC pipes. While it may be possible to create joints without it, using primer guarantees optimal strength. It is especially recommended for joints that will have liquid media passing through them.

The primer initiates a chemical reaction that enhances the bonding process, resulting in secure connections.

PVC primer plays a crucial role in ensuring strong and secure joints when working with PVC pipes. Understanding the chemistry behind PVC primer can help you appreciate its importance in the pipe joining process. Let’s take a closer look at how primer softens PVC and facilitates the bonding process.

Understanding Chemical Reactions

Chemical reactions are at the heart of how PVC primer works. When the primer is applied to the PVC surface, it initiates a reaction with the pipe material. This reaction involves the primer’s chemical compounds and the PVC itself. The primer contains solvents and additives that interact with the PVC’s polymer structure, altering its properties temporarily.

One key component of the primer is a solvent, typically acetone or tetrahydrofuran (THF). These solvents help to dissolve the outer layer of the PVC pipe, exposing a fresh surface for bonding. By softening the PVC, the primer allows the adhesive to penetrate and bond effectively, creating a strong joint.

How Primer Softens Pvc

The softening effect of PVC primer is essential for successful bonding. When the primer is applied to the PVC surface, it penetrates the top layer, breaking down the polymer chains in the pipe material. This softening process allows the adhesive to seep into the PVC, creating a molecular bond that ensures the joint’s strength and durability.

The solvents present in the primer act as a catalyst, accelerating the softening process. They interact with the PVC’s polymer chains, weakening their structure temporarily. This softening effect enables the adhesive to flow into the nooks and crannies of the PVC surface, enhancing the bond’s overall integrity.

In addition to softening the PVC, the primer also acts as a cleaner, removing any dirt, grease, or oxidation that may hinder the bonding process. By ensuring a clean and prepared surface, the primer maximizes the adhesive’s effectiveness, resulting in a reliable and long-lasting joint.

To summarize, PVC primer works by initiating a chemical reaction with the PVC surface. Through the use of solvents and additives, the primer softens the PVC, allowing the adhesive to penetrate and create a strong bond. This chemical interaction ensures the joint’s durability and reliability.

By understanding the chemistry behind PVC primer, you can appreciate its vital role in the pipe joining process. The next time you work with PVC pipes, remember to include primer in your preparations for secure and robust connections.

To Prime Or Not To Prime?

PVC primer softens the PVC pipe and fittings, preparing them for the solvent cement. While it may be possible to create strong joints without primer, using it ensures the joints are as strong as possible, particularly for joints with liquid media passing through them.

When it comes to gluing PVC pipes, one question that often arises is whether or not to use PVC primer. Some people argue that primer is essential for creating strong joints, while others believe it is unnecessary. In this article, we’ll explore the arguments for and against using primer, as well as situations where primer may be optional.

Arguments For Using Primer

1. Improved Bond Strength: One of the main reasons to use PVC primer is that it improves the bond strength between the pipe and the adhesive. Primer softens the surface of the PVC, allowing the adhesive to penetrate more deeply and create a stronger bond.

2. Better Chemical Resistance: Primer also helps to protect PVC joints from chemical damage. When liquids pass through PVC pipes, they can sometimes react with the material and cause it to break down. Primer creates a barrier that helps to prevent this from happening.

3. Required by Building Codes: In some areas, building codes require the use of PVC primer when joining pipes. It’s important to check your local codes to ensure that you’re following the proper procedures.

Situations Where Primer May Be Optional

1. Non-Critical Applications: If you’re using PVC pipes for non-critical applications, such as irrigation or drainage systems, primer may not be necessary. In these cases, a strong adhesive bond may be sufficient.

2. Dry Fit Joints: If you’re fitting PVC pipes together in a dry fit joint, primer may not be necessary. Dry fit joints are those that are not glued together, but instead rely on pressure and friction to stay in place. In these cases, primer is not necessary.

3. Time Constraints: If you’re short on time, you may be tempted to skip the primer step. While this is not recommended, it is sometimes done in a pinch. Keep in mind that skipping primer can compromise the strength and durability of your joints.

In conclusion, while primer is not always necessary, it can be an important step in creating strong and durable PVC joints. If you’re unsure whether or not to use primer, it’s always best to err on the side of caution and follow the manufacturer’s instructions.

The Color Debate: Does It Matter?

When it comes to PVC pipe installation, many people wonder whether the color of the primer matters. While some may argue that it’s merely a matter of personal preference, others insist that the color of the primer can have a significant impact on the effectiveness of the joint. In this article, we’ll explore the purpose of colored primers and the regulations and best practices surrounding their use.

Purpose Of Colored Primers

The purpose of colored primers is to provide a visual indication that the primer has been applied to the PVC pipe before the cement. The color of the primer can vary depending on the manufacturer, but the most common colors are purple, blue, and clear. The color helps to ensure that the primer has been applied evenly and thoroughly to the pipe, which is essential for creating a strong joint.

Some people believe that the color of the primer can affect the strength of the joint. However, there is no scientific evidence to support this claim. As long as the primer has been applied properly, the color should not make a difference.

Regulations And Best Practices

While there are no specific regulations regarding the color of PVC primer, there are best practices that should be followed. For example, it’s important to use a primer that is specifically designed for use with PVC pipe. This will ensure that the primer is compatible with the pipe material and will provide the best possible bond.

It’s also important to apply the primer evenly and thoroughly to the pipe. This can be done using a brush or an applicator pad. The primer should be allowed to dry completely before the cement is applied. This usually takes a few minutes, but it’s important to follow the manufacturer’s instructions to ensure that the primer has dried properly.

In conclusion, the color of PVC primer may not matter in terms of joint strength, but it does serve an important purpose in ensuring that the primer has been applied properly. By following best practices and using a primer that is designed for use with PVC pipe, you can ensure that your joints are strong and reliable.

After The Spill: Cleaning Up Primer

PVC primer is an essential step when gluing PVC pipes, as it starts the chemical reaction that softens the PVC, ensuring a strong joint. It also acts as a cleaner, removing grime and preparing the surface for the cement. Using primer is crucial for creating durable and reliable PVC pipe joints.

Dealing With Accidental Spills

Accidental spills happen, especially when working with PVC primer. It’s important to act quickly to prevent any permanent stains or damage. Here are some steps to effectively deal with accidental spills:

- Wear protective gloves and goggles to ensure your safety.

- Contain the spill by using absorbent materials such as paper towels or rags.

- Wipe the affected area gently to remove as much primer as possible.

- If the spill is on a porous surface, like fabric or carpet, blot the area instead of rubbing to avoid spreading the primer.

- Dispose of the contaminated materials properly according to local regulations.

- Clean the area with a mild detergent and warm water to remove any remaining residue.

- Allow the area to dry completely before using it again.

Removing Primer Stains

If you’re dealing with primer stains that have already dried, don’t worry. With the right approach, you can effectively remove these stubborn stains. Here’s how:

- Scrape off any excess dried primer using a plastic scraper or a blunt knife.

- Apply a small amount of acetone or nail polish remover to a clean cloth.

- Gently dab the stained area with the cloth, working from the outside towards the center.

- Continue dabbing until the stain starts to lift.

- Rinse the area with warm water and mild detergent to remove any residue.

- Repeat the process if necessary until the stain is completely gone.

- Allow the area to air dry.

Remember to always test any cleaning solution on a small, inconspicuous area first to ensure it doesn’t cause any damage or discoloration.

By following these steps, you can effectively clean up PVC primer spills and remove any stains that may occur. Remember to act quickly and take proper precautions to protect yourself and your surroundings.

Credit: www.plumbingsupply.com

Credit: m.youtube.com

Frequently Asked Questions

Do You Really Need Pvc Primer?

Using PVC primer is essential for ensuring the strength and durability of PVC pipe joints, especially for those carrying liquids. While it may be possible to create strong joints without primer, using it ensures the joints are as strong as possible.

Do You Let Pvc Primer Dry Before Cement?

No, you should not let PVC primer dry before cementing. The primer should still be wet when you apply the cement. While it is possible to create strong joints without using primer, it is recommended to use it on any joints that will have liquid media passing through them to ensure maximum strength.

The primer acts as a cleaner and softens the surface to prep for the fusion process. Make sure to start with clean material, cut the PVC pipe squarely, debur and bevel, apply primer, apply PVC glue, wipe off excess glue and primer, and then wait for the joint to cure.

Is Purple Pvc Primer Required?

Purple PVC primer is not required, but it is recommended for creating strong joints. While it is possible to create strong joints without primer, using primer ensures that the joints are as strong as possible, especially for joints that will have liquid media passing through them.

The primer softens the PVC and prepares it for the solvent cement, resulting in a stronger bond.

Will Pvc Primer Remove Pvc Glue?

Yes, PVC primer can remove PVC glue. The primer and solvent cement used in PVC pipe joints create a chemical reaction that essentially melts the two PVC pieces together, creating a solvent weld. If you need to remove the glue, you will need to use PVC primer to break down the bond between the pieces.

What Is The Purpose Of Pvc Primer?

PVC primer is used to soften the surface and prepare it for the application of PVC cement. It also removes grime and dirt.

Conclusion

To conclude, PVC primer plays a crucial role in creating strong and reliable joints between PVC pipes. While it may be possible to skip the primer and still achieve some level of success, it’s always better to use it for added strength and security.

The primer acts as a cleaner and softens the PVC surface, allowing for better adhesion when the cement is applied. So, if you want to ensure your PVC pipes stay securely joined, using primer is definitely the way to go.