When you’re tackling a tough job and need a reliable tool to get things done, choosing between a pry bar and a crowbar can feel overwhelming. You might wonder which one is best suited for your task, or if there’s even a difference between the two.

This is a decision that could impact not only the efficiency but also the safety of your work. With so much riding on the right choice, understanding the unique features and benefits of each tool is crucial. Imagine the satisfaction of effortlessly prying apart materials or lifting heavy objects with ease, simply because you made an informed decision.

Dive into this article and discover which tool deserves a spot in your toolbox, ensuring every project you undertake is a success. Your next project might just become easier than you ever imagined.

Historical Background

Have you ever wondered about the tools that have shaped the world? Pry bars and crowbars are two simple yet powerful tools with rich histories. Understanding their origins and development can offer insights into their uses today.

Origins Of Pry Bars

Pry bars have been around for centuries. Their invention was driven by the need for a tool to lift heavy objects effortlessly. They were originally crafted from sturdy materials like iron, ensuring durability.

Imagine a blacksmith in the early days, hammering and shaping iron to create the first pry bars. These tools were essential for construction and everyday tasks. They evolved from simple sticks to finely crafted tools, reflecting advancements in metalworking.

Think about the challenges people faced without modern machinery. Pry bars were vital for moving large stones and logs, making them indispensable in ancient construction projects. They were the unsung heroes behind the scenes.

Development Of Crowbars

Crowbars emerged as a versatile tool, evolving from the basic pry bar design. Their development focused on enhancing leverage and grip. With a curved end, crowbars became perfect for prying and breaking.

Picture yourself in the 19th century, using a crowbar to dismantle a wooden crate. Its design allowed for efficient force application, making it a go-to tool for demolition tasks. Crowbars adapted to various needs over time.

Consider the ingenuity of craftsmen who refined the crowbar design. They added features like nail pullers and textured grips, making them more user-friendly. This evolution showcases the continuous quest for better functionality.

Have you used a pry bar or crowbar in your DIY projects? These tools have a fascinating history that influences their design and use today. Their evolution reflects human innovation and the drive for practicality.

Design And Structure

Pry bars and crowbars differ in design and structure. Pry bars are slim, flat, and designed for precision tasks. Crowbars are thicker and heavier, ideal for forceful tasks like demolition. Both tools serve distinct purposes, making them essential for various projects.

When you’re staring at a stubborn nail or locked door, the right tool can make all the difference. Pry bars and crowbars are your trusty companions in these situations, but understanding their design and structure can help you choose the perfect one. Let’s delve into the design intricacies that set these two apart.Material Composition

Both pry bars and crowbars are typically made from durable materials like steel or titanium. Steel is common due to its strength and affordability. Titanium, though pricier, offers superior strength with less weight. Have you ever wondered why your crowbar feels heavier than your pry bar? It’s usually because crowbars are often constructed with solid steel, making them heftier and ideal for heavy-duty tasks. Pry bars, on the other hand, might have a hollow design, reducing weight without sacrificing strength.Shape And Size Variations

The shape and size of these tools can significantly influence their effectiveness. Crowbars usually have a curved end, perfect for pulling nails or prying apart materials. This curvature allows you to leverage more force with less effort. Pry bars often come in various lengths and shapes, including flat, angled, or even hooked tips. Imagine the ease of slipping a flat pry bar under a stubborn floorboard. Its design ensures precise control, making it a favorite for delicate tasks. Size matters too. A longer crowbar might be your go-to for significant demolition work, while a compact pry bar can be your pocket-friendly helper for quick fixes around the house. Design isn’t just about aesthetics; it’s about function. Next time you reach for a tool, think about the task at hand. Will a heavier crowbar help you break through that barrier, or is a nimble pry bar your best bet?Functionality

Understanding the functionality of pry bars and crowbars is crucial. Both tools serve different purposes despite their similar appearance. Knowing their functions can greatly assist in choosing the right tool for the job.

Common Uses Of Pry Bars

Pry bars excel in precision tasks. They are designed for delicate prying. Removing nails and opening crates are common uses. Their thin, flat ends make them ideal for tight spaces. Craftsmen often prefer them for detailed work.

These tools offer control in small projects. Minimal damage to surfaces is a key benefit. They are handy for home improvement tasks. Pry bars are often used in carpentry and remodeling. Their lightweight design aids in easy handling.

Applications For Crowbars

Crowbars are built for heavy-duty tasks. They handle larger, tougher jobs. Breaking apart materials is their specialty. Demolition work often requires their strength. Their robust design offers high leverage.

Crowbars are preferred in construction and heavy lifting. They are effective in dismantling structures. Removing stubborn nails and bolts is easier with them. Their curved design aids in prying and pulling. Suitable for outdoor and industrial use.

Strength And Durability

Pry bars and crowbars are essential tools for demolition tasks. Their strength and durability make them reliable. Each tool offers unique material properties. Understanding these can help choose the right tool.

Comparing Material Strength

Pry bars often use alloy steel, which is tough. This material provides good resistance against bending. Crowbars usually feature carbon steel. Carbon steel is known for its hardness. This makes crowbars excellent for heavy-duty tasks.

Alloy steel in pry bars is lighter. It’s easier to handle for longer periods. Carbon steel is heavier, offering more force. Each material serves specific needs. Choosing depends on the task type.

Longevity And Wear

Durability is critical for both tools. Pry bars resist wear due to their alloy composition. This extends their lifespan significantly. Crowbars, with carbon steel, excel in strength. They withstand more force over time.

Regular use can affect any tool. Proper maintenance ensures longer service. Inspecting and cleaning helps. A well-maintained tool lasts much longer. Investing in quality tools pays off in the long run.

Ease Of Use

When deciding between a pry bar and a crowbar, one of the key factors is how easy they are to use. Ease of use can make or break your project experience. Whether you’re a seasoned DIY enthusiast or just starting, understanding the handling and portability of these tools is crucial.

Handling And Grip

Handling a tool comfortably can make all the difference in your work efficiency. Pry bars often come with a finer handle, making them easier to maneuver in tight spaces. You can feel the control in your grip, and it helps in tasks requiring precision.

On the other hand, crowbars are typically designed for heavy-duty tasks. They have a thicker grip, which might be less comfortable for small hands. Have you ever tried pulling nails or prying apart wooden pallets? A pry bar’s narrow grip will feel like a natural extension of your hand.

Portability And Storage

Portability is another aspect where pry bars have an edge. Their sleek design makes them easier to carry around. You can tuck it into a tool bag without much hassle.

Crowbars, with their bulkier design, might pose a challenge in terms of storage. They demand more space and can be cumbersome to transport. If you frequently move between job sites or need a tool for home repairs, the compact nature of a pry bar is a blessing.

Are you considering the space in your toolbox or the back of your truck? Remember, every inch counts, especially when you’re on the go. Choose wisely based on how and where you’ll use it.

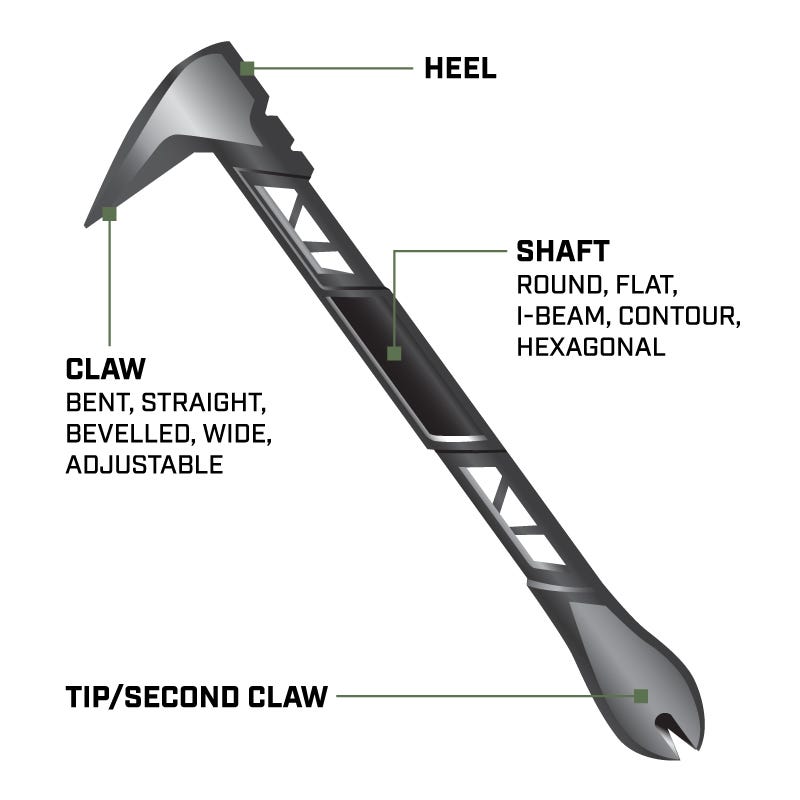

Credit: specopstools.com

Safety Considerations

Choosing between a pry bar and a crowbar requires careful attention to safety. Always wear protective gear, including gloves and goggles. Ensure the tool’s condition is good, with no cracks or rust. Use the tool as intended to prevent accidents and damage.

When choosing between a pry bar and a crowbar, safety should be your top priority. Both tools are indispensable for demolition and construction tasks, but improper use can lead to injuries. Ensuring you understand the distinct features and safe handling of each can make all the difference.Proper Usage Techniques

Knowing how to properly wield these tools is key to safety. Imagine trying to pry open a stubborn wooden crate. Using a pry bar, you can achieve precision without exerting excessive force. Its thin, flat end is designed for control. A crowbar, on the other hand, demands careful handling due to its heft. It’s perfect for tasks requiring brute force, like lifting heavy objects or breaking through walls. It’s important to assess the task at hand and choose the tool that best matches your needs. This reduces the risk of accidents caused by misuse.Avoiding Common Injuries

Common injuries with these tools often involve pinched fingers and strained muscles. Have you ever tried to use a crowbar without a secure grip? Your hands might slip, leading to painful blisters or bruises. Wearing gloves can provide a better grip and protect against minor injuries. Additionally, overestimating your strength while using a crowbar can result in back or shoulder strains. Try using your legs to lift, not your back, and maintain a balanced stance. Consider this: how many times have you seen someone struggle with a task just because they didn’t use the right tool? Recognizing the strengths and limitations of pry bars and crowbars can prevent unnecessary harm. Remember, safety is not just about using the right tool; it’s about using it wisely.Cost And Availability

When deciding between a pry bar and a crowbar, understanding their cost and availability is essential. Both tools are common in construction and DIY projects. Knowing their price range and market presence helps in making an informed choice.

Price Range Analysis

Pry bars generally cost less than crowbars. A basic pry bar can start around $10. Higher-end models may reach up to $50. Crowbars, on the other hand, often start at $15. Premium crowbars can cost over $60. The material and brand influence the price significantly. Pry bars made of stainless steel tend to be pricier. Crowbars made of forged steel also demand a higher price. For budget-conscious buyers, a basic pry bar offers value.

Market Availability

Pry bars are widely available in hardware stores. They are common in both physical and online markets. Crowbars are also easy to find in these places. Most home improvement stores stock both tools. Online platforms have a vast selection of brands and models. Availability varies by region and demand. In urban areas, choices are plentiful. Rural areas may have limited options. Online shopping can bridge this gap effectively. Comparing prices online can lead to better deals.

Credit: specopstools.com

User Preferences

User preferences play a crucial role in choosing between a pry bar and a crowbar. Both tools are similar, yet they appeal to different users. Understanding these preferences helps in making the right choice. Factors like comfort, usability, and effectiveness are often considered. Let’s explore what different users have to say.

Feedback From Professionals

Professionals often prefer tools that ensure efficiency and reliability. Many carpenters and construction workers choose pry bars. They value the precision and control these tools offer. The slim design of a pry bar helps in tight spaces. It allows for more detailed work without causing damage.

In contrast, some demolition experts favor crowbars. They appreciate the robust build and leverage these tools provide. For heavy-duty jobs, a crowbar’s strength is unmatched. It handles tasks that require more force with ease.

Opinions From Diy Enthusiasts

DIY enthusiasts often seek versatility in their tools. Many prefer pry bars for home projects. They find the tool easy to handle for various tasks. From pulling nails to prying open tight lids, a pry bar is handy.

Some DIYers opt for crowbars for their durability. They trust the tool to withstand heavy use over time. A crowbar is often seen as a reliable tool for larger projects. Its ability to handle rough tasks makes it a favorite.

Credit: www.jamtkrogen.com

Frequently Asked Questions

What Is The Main Difference Between Pry Bar And Crowbar?

A pry bar is smaller and used for precision tasks. A crowbar is larger, ideal for heavy-duty work.

Which Tool Is Better For Demolition Projects?

Crowbars are better for demolition. They are strong and can handle heavy materials, unlike pry bars.

Can I Use A Pry Bar For Removing Nails?

Yes, a pry bar can remove nails. It is handy for small tasks like this.

Are Crowbars More Durable Than Pry Bars?

Crowbars are generally more durable. They are built for heavy work and last longer in tough conditions.

Is A Pry Bar Safer For Delicate Tasks?

Yes, pry bars are safer for delicate tasks. Their smaller size helps avoid damage to surfaces.

Conclusion

Choosing between a pry bar and a crowbar depends on your needs. Pry bars are great for delicate tasks. They help in small, precise jobs. Crowbars handle heavy-duty work. They excel in demolition and leverage tasks. Think about your project.

Consider the size and weight of the tool. Both have unique benefits. Both tools are essential in toolkits. Use wisely for best results. Always prioritize safety while using them. Your project will determine the right tool. Remember, each tool has its strengths.

Choose the one that fits your task best.