Imagine you’re standing in the hardware aisle, staring at a bewildering array of pipes and fittings. You need to make a decision, but you’re not sure whether a pipe union or a coupling is the right fit for your project.

It’s a common dilemma that can feel overwhelming, especially when you want to ensure the longevity and safety of your plumbing system. But don’t worry—this article is here to make your choice crystal clear. By the end of this read, you’ll not only understand the key differences between pipe unions and couplings, but also how to choose the perfect one for your needs.

Let’s dive into the fascinating world of plumbing connections and unravel the mystery together.

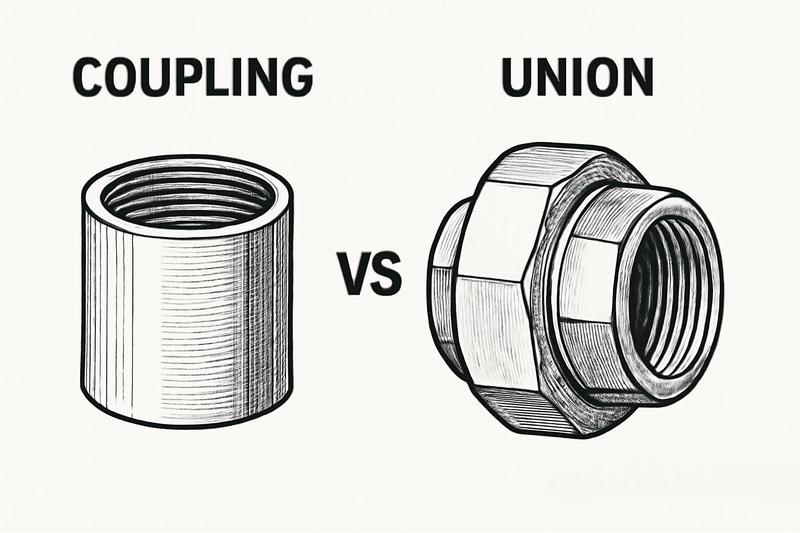

Pipe Union Basics

Understanding pipe unions is essential in plumbing and piping systems. Pipe unions serve as connectors, allowing easy assembly and disassembly of pipes. They ensure secure joints without twisting the pipes, which saves time and effort during maintenance. Learn about their components and design, and explore their common applications to grasp their importance.

Components And Design

A pipe union consists of three main parts: the nut, female end, and male end. The nut tightens the connection, while the female and male ends ensure a snug fit. This design allows pipes to be joined and separated without hassle. Unions are available in various materials like brass, stainless steel, and plastic. The choice of material depends on the specific requirements of the piping system.

Common Applications

Pipe unions are widely used in residential plumbing systems. They facilitate easy removal and replacement of pipes during repairs. In industrial settings, unions connect pipes in machinery and equipment. They allow quick disassembly for maintenance or inspection. Unions are also found in HVAC systems, enabling efficient connection of heating and cooling lines.

Credit: www.pipesandfittings.com

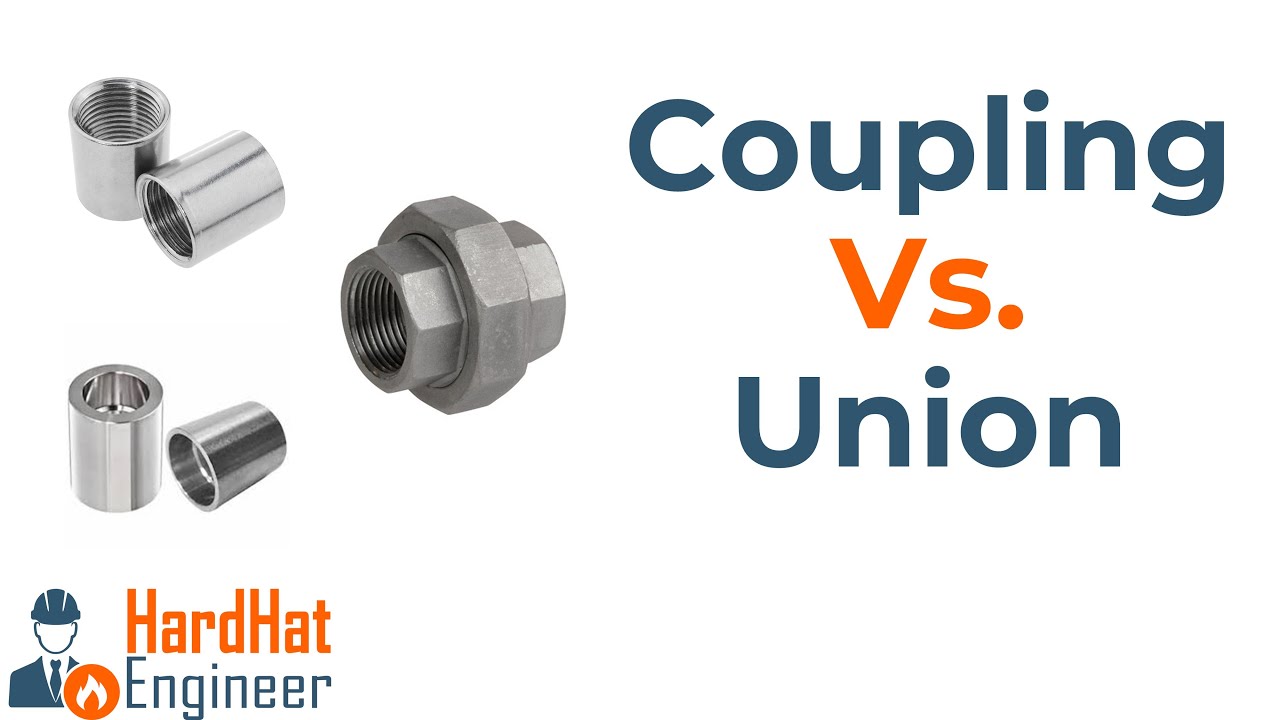

Coupling Basics

Understanding the essentials of pipe coupling can make a world of difference in your plumbing or construction projects. Couplings serve as vital connectors between pipe sections, ensuring a seamless flow of materials. Whether you’re fixing a leak or setting up a new piping system, knowing the basics of coupling can save you time and headaches. Let’s dive into the types and materials of couplings, and explore their typical uses.

Types And Materials

Couplings come in various types, each serving different purposes. The most common are sleeve, compression, and threaded couplings.

- Sleeve Couplings:Simple yet effective, these are cylindrical sleeves that fit over the ends of pipes.

- Compression Couplings:Often found in water supply systems, they use a gasket or rubber ring to seal connections.

- Threaded Couplings:Ideal for metal pipes, these require threading on both ends to ensure a tight fit.

Materials matter too. Couplings are made from a range of materials, including metal, plastic, and rubber.

- Metal:Known for durability and strength, metals like steel and brass are commonly used.

- Plastic:Lightweight and corrosion-resistant, plastic couplings are perfect for non-metal pipes.

- Rubber:Flexible and versatile, rubber couplings are used in situations requiring vibration absorption.

Have you ever thought about how the choice of material can affect the longevity and efficiency of your piping system? Picking the right type and material is crucial for a successful installation.

Typical Uses

Couplings are used in various applications, making them indispensable in piping systems.

- Water Supply:Compression couplings are frequently used to connect water pipes, ensuring leak-free connections.

- Gas Lines:Threaded couplings are preferred for gas lines, where safety and tight connections are paramount.

- Drainage Systems:Sleeve couplings are ideal for connecting drainage pipes, allowing for smooth flow and easy maintenance.

Think about the last time you faced a plumbing issue. Having the right coupling could have made a significant difference. Next time, consider the specific needs of your project—whether it’s the type of fluid transported or the environmental conditions—and choose your coupling wisely.

Are you prepared to make informed decisions about couplings in your next project? Understanding these basics will empower you to tackle challenges with confidence.

Installation Process

Choosing between a pipe union and a coupling depends on the need for disconnection. Pipe unions allow easy disconnection for maintenance. Couplings are ideal for permanent connections, ensuring a secure fit. Each serves a unique purpose in plumbing tasks.

The installation process is a crucial aspect to consider when choosing between a pipe union and a coupling. Understanding the differences in how each is installed can save you time and effort in your project. Whether you’re tackling a DIY task or overseeing a professional job, knowing the installation process helps you make informed decisions.Pipe Union Installation

Installing a pipe union is a straightforward task, but it requires precision. First, ensure that the pipes you’re connecting are clean and free from debris. This prevents leaks and ensures a snug fit. You start by screwing one end of the union onto the first pipe. Make sure it is tight but don’t overdo it, as this can damage the threads. Next, align the second pipe and screw the other end of the union onto it. Use a wrench to tighten the union nut and bring the two pipes together. The union’s design allows for easy disconnection, which is helpful for future maintenance.Coupling Installation

Installing a coupling is usually simpler but requires careful alignment. Begin by measuring the pipes to ensure they fit snugly inside the coupling. Slide the coupling over one pipe, ensuring it covers the pipe evenly. If it’s a slip coupling, you may need to slide it further onto the pipe to make space for the second pipe. Align the second pipe with the first and slide the coupling over both ends. Tighten any clamps or screws if your coupling has them. Properly installed couplings are reliable, but misalignment can lead to leaks. Have you ever struggled with aligning pipes perfectly? It’s a common challenge that can be overcome with patience and a steady hand. Remember, the right tools can make a world of difference. Is your toolbox equipped with the essentials for a smooth installation?Durability And Maintenance

Pipe unions offer easy disassembly for maintenance, perfect for frequent inspections. Couplings provide strong, lasting connections, ideal for permanent installations. Both ensure durability with proper care.

When considering the durability and maintenance of pipe unions versus couplings, you might wonder which one stands the test of time better and requires less upkeep. Both have their unique characteristics and can excel in different situations. In this section, we’ll compare them to help you make an informed decision for your plumbing or industrial needs.Wear And Tear Factors

Every material faces wear and tear over time, but the extent can vary. Pipe unions are often praised for their robustness. They allow pipes to be easily disconnected and reconnected, which minimizes stress on the joints. Couplings, on the other hand, are more permanent solutions. They’re typically secured with solder or glue, which can degrade over time, especially in environments with fluctuating temperatures or exposure to chemicals. Imagine you’re in an older building where the plumbing hasn’t been updated for decades. The couplings might have worn out due to the constant temperature changes, leading to leaks. In contrast, unions may still hold strong, simply requiring tightening to maintain a perfect seal.Maintenance Practices

Regular maintenance can significantly extend the lifespan of both pipe unions and couplings. For unions, simple practices like checking for tightness and replacing worn-out gaskets can prevent leaks. Couplings, however, may demand more effort. You might need to monitor for corrosion or any signs of adhesive breakdown. If you’re in a high-humidity area, this becomes even more crucial. A friend of mine once shared how she avoided a major plumbing disaster by routinely checking the unions in her basement. She caught a minor leak early, saving her from a costly repair. This highlights the importance of proactive maintenance. Have you ever thought about how routine checks can prevent bigger issues later? By investing a little time now, you can save yourself from the hassle and expense of unexpected repairs. Remember, the choice between pipe unions and couplings doesn’t have to be daunting. Consider your environment, the specific application, and how much maintenance you’re willing to commit to.Cost Considerations

When you’re deciding between a pipe union and a coupling, cost is an important factor. Both materials and labor costs can significantly impact your budget. Understanding these can help you make a more informed decision.

Material Costs

Pipe unions are usually more expensive than couplings. This is because unions have additional components like nuts and bolts, which allow for easy disconnection. If you’re working with a tight budget, consider whether the added convenience is worth the extra expense.

Couplings, on the other hand, are generally simpler and less costly. They offer a straightforward connection without the bells and whistles. Think about your project’s needs. Do you need the flexibility to easily disconnect pipes, or is a permanent connection sufficient?

Labor Costs

Installing pipe unions often requires less labor time. Their design allows for quick assembly and disassembly. This can save you money on labor, especially in projects where time is of the essence.

Couplings may involve more labor, particularly if they require welding or adhesive. The longer installation time could increase costs. Consider the skill level of your labor force. Do they have the expertise to work efficiently with more complex connections?

Weighing material and labor costs is crucial in your decision-making process. What are your priorities? Is upfront savings more important, or do you value long-term convenience and flexibility?

Credit: www.youtube.com

Performance And Efficiency

When choosing between pipe unions and couplings, performance and efficiency are crucial factors to consider. Both components connect pipes, but their impact on overall system effectiveness can differ. Understanding how each performs under pressure and handles potential leaks is key to making an informed decision.

Pressure Handling

Pipe unions are designed to handle high-pressure systems effectively. They provide a robust connection that can withstand significant force without compromising integrity. This makes them ideal for applications where pressure fluctuations are frequent.

On the other hand, couplings are generally used in systems with moderate pressure requirements. They are excellent for everyday use but might not be the best choice for high-pressure environments. Consider the specific pressure needs of your system when deciding between the two.

Leak Prevention

Leak prevention is a critical aspect of any piping system. Pipe unions excel in this area due to their threaded design, which offers a tight, secure fit. This reduces the chance of leaks, providing peace of mind, especially in sensitive installations.

Couplings also provide a good seal, but they might be more prone to leaks if not properly installed. Ensure all connections are tight and secure to mitigate any risks. How confident are you in your system’s ability to prevent leaks?

Choosing between a pipe union and a coupling isn’t just about functionality—it’s about efficiency and reliability. By understanding how each component performs under pressure and prevents leaks, you can ensure your system runs smoothly and effectively. Consider your specific needs and trust in the right tool for the job.

Suitability For Projects

Choosing between pipe unions and couplings depends on project needs. Pipe unions are ideal for frequent disconnections, offering easy maintenance. Couplings suit permanent connections, providing robust strength in pipelines. Each has its own benefits based on the project requirements.

When choosing between pipe unions and couplings for your project, understanding their suitability is crucial. You wouldn’t want to make a decision that could lead to leaks or inefficiencies. Each option serves different needs and environments. So, how do you decide which is right for your specific project? Let’s dive into their applications to help you make an informed choice.Industrial Applications

In industrial settings, where high pressure and temperature are common, choosing the right connector can make or break your project. Pipe unions are often preferred in these environments. They allow for quick disassembly and maintenance, which is vital when dealing with complex machinery. Consider a factory floor where time is money. If a pipeline needs maintenance, unions enable workers to separate the pipes without disturbing the entire system. This saves time and reduces downtime, making unions a practical choice in industrial applications. Couplings, on the other hand, are usually more permanent. They work well for projects that don’t require frequent maintenance or disassembly. If you’re dealing with a setup that’s intended to last with minimal intervention, couplings might be the way to go.Residential Applications

In residential projects, the dynamics change. Here, ease of installation and cost-effectiveness often take precedence. Pipe unions can be ideal for situations where future modifications or repairs are likely. Imagine installing a home water filtration system. You might want the flexibility to replace parts without overhauling the entire setup. However, for simpler, more permanent installations like connecting two sections of a garden hose, couplings are often sufficient. They’re straightforward and easy to use, making them perfect for DIY enthusiasts who want a quick fix. Think about how frequently you’ll need to access the connection. If it’s in a hard-to-reach place, opting for unions could save you a lot of hassle later. But if it’s a straightforward task, couplings can be a more economical choice. In both industrial and residential settings, the key is to align your choice with the project’s demands. Have you ever found yourself in a situation where a simple decision made all the difference? Making the right choice between a pipe union and coupling could be that decision for your project.

Credit: www.homedepot.com

Frequently Asked Questions

What Is The Main Difference Between Pipe Union And Coupling?

Pipe unions allow easy disconnection. Couplings are for permanent joining. Unions have threads; couplings may not.

When Should You Use A Pipe Union?

Use a pipe union for frequent disconnection. It’s ideal for maintenance or repairs.

How Does A Pipe Coupling Work?

Pipe couplings connect two pipes. They provide a continuous flow path and can be threaded or socketed.

Are Pipe Unions Reusable?

Yes, pipe unions are reusable. They can be taken apart and reassembled easily without damage.

Can Pipe Couplings Handle High Pressure?

Yes, some couplings handle high pressure. Choose the right type for your specific application needs.

Conclusion

Choosing between pipe unions and couplings depends on your project needs. Pipe unions offer easy disconnection and maintenance. Ideal for temporary setups. Couplings are more permanent. They provide strong, leak-proof connections. Often used in fixed installations. Consider the material compatibility of both options.

Also, think about the pressure and temperature conditions. Each has its own advantages. Weighing these factors helps in making the right decision. Always prioritize safety and efficiency in your plumbing projects. With the right choice, your system will function smoothly and effectively.