Are you planning a home renovation or starting a new construction project? Choosing the right materials can make all the difference in durability and success.

When it comes to cement boards, you might find yourself torn between two popular options: Permabase Cement Board and Durock. Both promise strength and reliability, but which one is truly the best fit for your needs? Imagine saving time, money, and potential headaches by making the right choice from the start.

Understanding the key differences between these two options could be your secret weapon. We’ll break down everything you need to know, helping you make an informed decision that aligns perfectly with your project goals. Don’t miss out on discovering which cement board will give you the peace of mind you deserve. Dive in, and let’s unravel the mystery together.

Material Composition

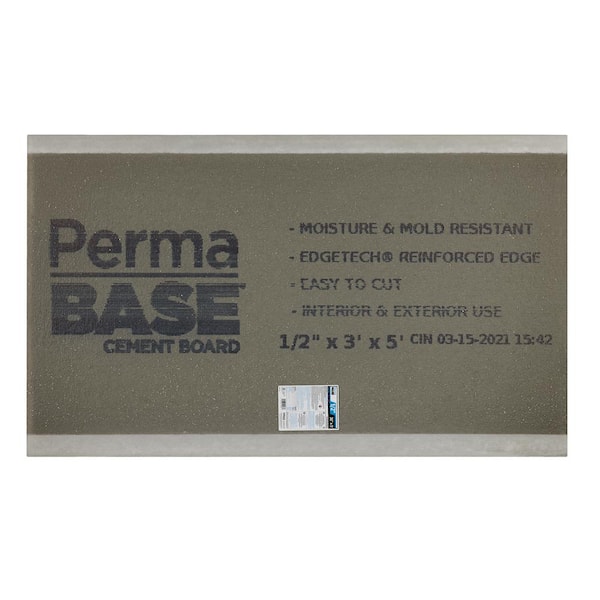

Permabase Cement Board is made from Portland cement, aggregates, and fiberglass mesh, offering strong moisture resistance. Durock consists of Portland cement, lightweight aggregates, and a polymer-coated glass-fiber mesh, providing durability and flexibility in various installations. Both boards excel in wet environments, ensuring long-lasting performance.

Understanding the material composition of Permabase Cement Board and Durock is crucial for anyone looking to make informed decisions in construction or remodeling projects. The materials used in these boards not only influence their durability and performance but also their suitability for specific projects. Let’s take a closer look at what each product is made of and what this means for you.Permabase Cement Board Composition

Permabase Cement Board is known for its unique blend of materials. It comprises a solid core made of Portland cement, combined with aggregates and reinforced with fiberglass mesh. This combination offers impressive strength and moisture resistance. The fiberglass mesh reinforcement ensures that Permabase maintains its integrity even in wet environments. This makes it a great choice for areas exposed to water, like bathrooms and kitchens. Its resistance to mold and mildew adds another layer of confidence in its application.Durock Cement Board Composition

Durock Cement Board also features a robust blend of materials, primarily Portland cement, and is reinforced with polymer-coated fiberglass mesh. This composition offers a balance between strength and workability, making it a popular choice among professionals. The polymer coating on the fiberglass helps Durock provide enhanced moisture resistance. This makes it suitable for a variety of applications, including tile backing in wet areas. Additionally, Durock’s lighter weight compared to other cement boards can make installation easier, especially in overhead applications.Comparative Insights

When comparing the two, both Permabase and Durock cement boards offer strong moisture resistance, which is essential for areas prone to water exposure. However, the reinforcement methods differ slightly, impacting their performance in specific scenarios. Permabase’s use of fiberglass mesh offers excellent rigidity, which can be beneficial for projects requiring a stable surface. On the other hand, Durock’s polymer-coated mesh provides a more balanced approach, offering ease of handling without compromising on durability. Have you ever wondered how these differences might affect your project outcomes? Choosing between these boards could come down to the specific needs of your project. Do you prioritize ease of installation, or is maximum durability your goal? Understanding these subtle differences can guide you in selecting the right product for your home improvement project. By considering the composition of each board, you’ll be better equipped to make a choice that aligns with your specific needs and expectations.Durability And Strength

Durability and strength are key factors in choosing the right cement board. They determine how well a material can withstand wear and tear. These qualities ensure longevity, especially in areas exposed to moisture or temperature changes.

Comparing Durability: Permabase Cement Board

Permabase Cement Board boasts impressive durability. It resists moisture, preventing damage from water exposure. This makes it ideal for bathrooms and kitchens. The board maintains its integrity over time. Less chance of warping or cracking.

Comparing Durability: Durock Cement Board

Durock Cement Board also showcases notable durability. It is designed to handle tough conditions. It withstands impact and pressure effectively. This ensures reliable performance in various settings. Durock remains robust and sturdy throughout its use.

Strength Analysis: Permabase Cement Board

Permabase’s strength lies in its dense composition. It offers resistance against physical stress. Suitable for high-traffic areas or heavy installations. The board provides a stable base for tiles and other materials. A strong choice for demanding projects.

Strength Analysis: Durock Cement Board

Durock is recognized for its solid build. It supports heavy loads without bending. This makes it perfect for flooring and walls. Its strength contributes to reliable installations. A dependable option for construction needs.

Water Resistance

Water resistance is crucial in construction materials for bathrooms and kitchens. These areas are constantly exposed to moisture, requiring durable solutions. Permabase Cement Board and Durock are popular choices. They both offer excellent protection, but differ slightly in their properties.

Permabase Cement Board: Enhanced Water Resistance

Permabase Cement Board excels in water resistance. It features a dense core that repels moisture effectively. The board maintains its integrity, even after prolonged exposure. This makes it ideal for wet environments. Its composition prevents water absorption, ensuring long-lasting durability. Builders trust its reliability in high-moisture areas.

Durock: Reliable Water Resistance

Durock offers solid water resistance, suitable for most projects. It incorporates a unique cementitious blend. This blend reduces water penetration, enhancing durability. While not as dense as Permabase, it performs well in damp conditions. Durock is a dependable choice for bathrooms and kitchens.

Comparing Water Resistance: Permabase Vs. Durock

Permabase provides superior water resistance due to its dense core. This feature sets it apart from Durock. Durock, though less dense, still offers reliable protection. Both boards resist mold and mildew, promoting healthier environments. Choosing between them depends on specific project needs.

Ease Of Installation

Choosing between Permabase Cement Board and Durock often boils down to their ease of installation. Whether you’re a seasoned contractor or a DIY enthusiast, understanding the nuances of how these boards handle can make your project smoother and more efficient. Let’s break down the installation process in terms of weight, handling, cutting, and fastening to see how each board measures up.

Weight And Handling

Permabase Cement Board is known for its lighter weight compared to Durock. This can be a significant advantage if you’re working alone or have limited manpower. Lighter boards are easier to carry, position, and install without the need for extra hands.

Handling Durock, on the other hand, might require a bit more muscle. Its heavier composition provides sturdiness, but can be challenging for one-person installations. Think about your team’s strength and the project scale before making a choice. Will the extra weight slow you down, or is the added robustness worth it?

Cutting And Fastening

Permabase offers a smoother cutting experience. Its texture allows for cleaner cuts using basic tools like a utility knife or handsaw. This simplicity can save time and reduce frustration, especially if precision is key to your design.

Durock, while sturdy, might require power tools for cutting. This ensures durability but can complicate the process if you’re aiming for a straightforward installation. Fastening Durock is equally robust, requiring careful placement and securing to ensure it stays put.

Consider your toolkit and expertise. Do you have the right tools for Durock, or is Permabase’s ease of cutting more aligned with your current setup?

Both boards have their merits, but understanding their installation quirks helps you make an informed decision. What matters most in your project – ease of handling or the strength of the board? Your choice could define the pace and success of your installation journey.

Cost Comparison

Permabase Cement Board often costs less than Durock, offering a budget-friendly option. Durock, though pricier, provides durability and strength suitable for demanding projects.

When you’re planning a construction or renovation project, understanding the costs of materials is crucial. Comparing Permabase Cement Board and Durock can help you make an informed decision that suits your budget. Both options have their unique advantages, but how do they measure up in terms of price? Let’s break down the costs and see which one offers more value for your money.Material Costs

Permabase Cement Board and Durock are both popular choices for cement board needs. You might find that Permabase typically comes at a slightly higher price. For instance, while a 3×5 foot sheet of Durock might cost around $10, a similar sheet of Permabase could be priced at $12. This difference might not seem significant at first glance. However, if your project requires dozens of sheets, those extra dollars add up quickly. Always calculate the total cost based on the number of sheets you need.Installation Expenses

The installation process can also influence overall costs. Durock is known for being easier to cut and handle. This can save time and effort during installation, potentially reducing labor costs if you’re hiring professionals. On the other hand, Permabase, while slightly heavier, offers a smoother surface that may require less finishing work. This could save you on material costs related to finishing, such as joint compound or paint. Consider how much value you place on ease of installation versus finishing quality.Longevity And Maintenance

While initial costs are important, think about long-term savings. Permabase is often praised for its resistance to moisture and mold. This could mean fewer repairs and replacements over time, saving you money in the long run. Durock is also durable but might require more maintenance in wet environments. Weigh the upfront cost difference against the potential costs of maintenance and replacements. How much are you willing to invest now to save on future repairs?Personal Experience

During a bathroom renovation, I opted for Permabase for its moisture resistance. Initially, the cost was slightly higher compared to Durock. However, years later, the walls remained in excellent condition, proving the investment worthwhile. Have you considered how often you’d like to renovate or repair your space? Sometimes, spending a little extra now can lead to significant savings later.Cost-benefit Analysis

Ultimately, choosing between Permabase and Durock comes down to weighing immediate costs against long-term benefits. Consider your project’s specific needs and budget constraints. Are you looking for a quick, budget-friendly solution, or are you willing to invest a bit more for durability and reduced maintenance? Engage with these questions and analyze the cost implications carefully. Making the right choice could save you time, effort, and money in the future.Applications

Permabase Cement Board offers moisture resistance and durability, ideal for wet areas. Durock provides strong support for tiles, ensuring stability. Both are excellent choices for construction needs.

When deciding between Permabase Cement Board and Durock, understanding their applications can help you make the right choice for your project. These boards are popular for their durability and versatility in various construction environments. Here’s a closer look at how each can be used both inside and outside your home.Interior Use

Permabase and Durock are both excellent for interior applications, especially in areas exposed to moisture. Think about your bathroom or kitchen—both are places where moisture can cause havoc if not properly managed. In such spaces, these cement boards serve as a reliable substrate for tiles, ensuring your investment in tiles lasts longer. From my experience remodeling a bathroom, using a cement board like Permabase or Durock as a base under the tiles made the installation feel more secure and durable. Both boards can also be used in interior fire-rated assemblies. This is crucial for safety-conscious homeowners. So, have you considered using these boards behind a fireplace or stove for added peace of mind?Exterior Use

For exterior use, both Permabase and Durock offer unique benefits. They provide a solid base for exterior finishes, such as stucco or siding, protecting your home from the elements. Permabase is known for its water resistance, making it ideal for outdoor use. Picture your backyard oasis with a beautiful outdoor kitchen or a stunning tiled patio. Using Permabase can provide the necessary protection against weather damage. Durock, on the other hand, offers impressive durability in harsh climates. Its strong resistance to wind and rain makes it a great choice for homes in areas with extreme weather conditions. Which one fits your needs better? Consider the specific climate and conditions your project will face. Whether it’s a new outdoor entertainment area or a simple garden shed, choosing the right cement board can make a significant difference. As you plan your next renovation or build, think about how each board’s characteristics align with your specific needs. The right choice can lead to a long-lasting, beautiful result, both inside and outside your home.Fire Resistance

Permabase Cement Board and Durock offer impressive fire resistance features. Permabase provides enhanced durability against heat, making it ideal for high-temperature areas. Durock excels in fire protection, ensuring safety in residential and commercial spaces. Both boards present effective solutions for building fire-resistant structures.

When choosing materials for construction, fire resistance is a crucial factor that can make a significant difference in safety. You want your building materials to protect against fire hazards and provide peace of mind. Permabase Cement Board and Durock are popular choices, but how do they stack up against each other in terms of fire resistance?Permabase Cement Board: Fire Resistance Features

Permabase Cement Board is designed with fire resistance in mind. It is made from a combination of cement, sand, and reinforcing fibers, offering excellent durability and fire protection. This board is classified as a non-combustible material. It can withstand high temperatures, helping to prevent the spread of fire. If you’re installing in a high-risk area, Permabase’s ability to maintain structural integrity during a fire can be a game-changer. Wouldn’t you want that extra security for your project?Durock: How It Handles Fire

Durock is another heavy-duty cement board favored for its fire-resistant properties. Made from a mix of Portland cement, aggregate, and a fiberglass mesh, it provides a robust barrier against flames. The board is also non-combustible, similar to Permabase, and can endure high levels of heat. This makes it an excellent choice for areas prone to fire exposure. Imagine installing Durock in your home and knowing that it helps protect the structure from potential fire damage. Isn’t that a reassuring thought?Comparing The Two: Which Offers Better Fire Protection?

Both Permabase and Durock offer commendable fire resistance. They are non-combustible, providing a solid shield against fire. However, slight differences in their composition might influence your decision based on specific needs. Permabase tends to be lighter, which can make handling easier during installation. Durock, on the other hand, may offer a denser composition, which some believe could enhance fire protection. Which one aligns more with your project’s requirements?Practical Considerations For Installation

When installing either board, proper installation is key to maximizing fire resistance. Ensure that joints are properly sealed to prevent any fire from seeping through gaps. Have you thought about the extra protection you get by combining these boards with other fire-resistant materials, such as fire-rated drywall? Doing so can significantly increase your overall fire protection, providing an added layer of security. Isn’t it worth considering these factors before making your final decision?Real-world Applications And Testing

Testing environments often highlight the fire-resistant capabilities of both boards. Permabase and Durock have been subjected to rigorous fire tests to ensure their reliability in real-world conditions. These tests demonstrate that both boards maintain their integrity during fire exposure. Can you imagine the peace of mind this offers in a real-life scenario? Choosing the right material can be daunting, but focusing on fire resistance is a step in the right direction. Which board will you trust for your next project?

Credit: www.aconcordcarpenter.com

Environmental Impact

Environmental impact is a crucial factor in building materials. Both Permabase Cement Board and Durock are popular options. Understanding their ecological footprint helps make informed decisions.

Raw Material Sourcing

Permabase Cement Board uses recycled materials. This reduces waste and conserves resources. Durock also incorporates recycled content, but the proportion varies. Both aim to minimize environmental harm through sustainable sourcing practices.

Manufacturing Process

Permabase Cement Board is produced with energy-efficient methods. This helps reduce carbon emissions. Durock follows similar practices. Both companies prioritize eco-friendly manufacturing to lessen their environmental impact.

Transportation Footprint

Transportation affects the environmental impact of building materials. Permabase boards are lightweight. This results in lower transportation emissions. Durock boards are heavier, increasing fuel consumption during transport. Choosing local suppliers can further reduce the transportation footprint.

End-of-life Disposal

Both Permabase and Durock boards can be recycled. Proper disposal ensures minimal environmental impact. Recycling prevents these materials from ending up in landfills. This supports a circular economy and reduces waste.

User Reviews And Feedback

Understanding user reviews helps in making informed decisions. Both Permabase Cement Board and Durock have their unique features. Real user experiences provide valuable insights. Let’s dive into the reviews and feedback from actual users.

Durability Insights From Users

Many users praise Permabase for its high durability. It withstands extreme conditions without damage. Durock also receives positive feedback for its strength. Users report both boards last long with proper installation.

Installation Experiences

Permabase users note its ease of installation. Lightweight design aids in handling. Durock users mention its slightly heavier feel. Some find it challenging to cut compared to Permabase.

Moisture Resistance Feedback

Moisture resistance is a key feature. Permabase users appreciate its superior water resistance. It’s often preferred for wet areas. Durock also receives praise for moisture management. Users recommend it for bathroom and kitchen applications.

Customer Service And Support

Customer support is crucial for product satisfaction. Permabase users often commend their responsive support team. Durock users express similar satisfaction. Both brands provide helpful installation guides and troubleshooting assistance.

Overall Satisfaction

Overall, users express satisfaction with both products. Permabase is favored for easy handling and water resistance. Durock is valued for its strength and durability. User preferences often depend on specific project needs.

Credit: www.lowes.com

Expert Recommendations

Permabase Cement Board offers impressive durability and resistance to moisture, making it ideal for wet areas. Durock, known for its strength and versatility, is favored for various construction projects. Both options serve different needs, offering reliable solutions in building.

When you’re deciding between Permabase Cement Board and Durock for your next project, expert recommendations can provide invaluable insights. These professionals often have years of experience and have worked with both materials extensively. Their advice can steer you towards the right choice based on your specific needs.Understanding The Composition

Experts stress the importance of understanding the composition of each board. Permabase is praised for its lightweight nature, making it easier to handle, especially if you’re working solo. Durock, on the other hand, is robust and offers superior strength, often recommended for high-impact areas. Which one aligns with your project’s demands? Consider the ease of installation versus the durability required.Performance Under Pressure

In areas prone to moisture, like bathrooms, experts often lean towards Durock for its water resistance. Permabase, while still reliable, may require additional waterproofing measures. How much time are you willing to spend on preparation? This consideration can significantly affect your project’s timeline.Cost Considerations

Budget constraints are a reality for many. Experts recommend comparing the cost-effectiveness of both options. Permabase might offer savings on the initial purchase and installation due to its lighter weight. Durock’s long-term benefits, with its durability, can mean fewer repairs down the line. Where do you prioritize spending—upfront or over the life of the project?Personal Experience Counts

Having worked with both boards, I found Permabase easier to cut and fit around corners. This was crucial during a kitchen remodel where precision was key. Meanwhile, Durock proved its worth in a basement renovation, where its sturdiness was non-negotiable. What past experiences can you draw upon to inform your choice?Final Thoughts: Making The Right Choice

Ultimately, experts advise that your choice should reflect the specific demands of your project. Consider the environment, budget, and your comfort with the installation process. Engage with professionals and gather multiple opinions. What do you prioritize most in your building projects? The answer might just guide you to the best choice for your needs.

Credit: www.homedepot.com

Frequently Asked Questions

What Are Permabase Cement Board Benefits?

Permabase offers excellent moisture resistance. It’s durable and easy to cut. Perfect for wet areas like bathrooms.

How Does Durock Differ From Permabase?

Durock is heavier and more rigid. It provides high impact resistance. Suitable for exterior walls and floors.

Which Board Is Better For Bathroom Walls?

Permabase is ideal for bathroom walls. It’s moisture-resistant and lightweight. Easier to install than Durock.

Can Permabase And Durock Be Used Outdoors?

Yes, both can be used outdoors. They resist weather conditions well. Ensure proper installation for durability.

Are Permabase And Durock Fire-resistant?

Both boards are fire-resistant. They provide safety in areas exposed to heat. Always follow installation guidelines.

Conclusion

Choosing between Permabase and Durock cement boards depends on your needs. Permabase offers moisture resistance and easy cutting. Durock is durable and versatile. Both work well in wet areas. Consider your specific project requirements. Think about budget, installation ease, and the environment.

Both materials perform well in different settings. The right choice ensures a long-lasting finish. Consult with professionals if unsure. They can provide tailored advice for your project. Proper installation is key. Whichever you choose, both are solid options. Make an informed decision for the best results.