Troubleshooting a Kohler engine starts with identifying symptoms and consulting the manual. Common issues include starting problems and irregular running.

Kohler engines power a wide range of equipment from lawn mowers to generators, standing out for their reliability and performance. Yet, like any mechanical device, they may occasionally encounter issues that disrupt their operation. A clear guide to troubleshooting can save time and reduce frustration, ensuring your Kohler engine returns to its optimal state swiftly.

Understanding the basics, from spark plug checks to fuel system inspections, is essential for effective troubleshooting. This approach not only aids in quick diagnostics but also in implementing the correct solutions. Our goal is to provide you with straightforward, actionable advice to tackle common Kohler engine problems, keeping your machinery in top condition.

Introduction To Kohler Engines

Kohler engines power a wide range of devices. From lawn mowers to generators, these engines bring life to the machines we rely on. Their reputation for durability makes them a go-to choice for both residential and commercial use.

Popularity In Various Applications

Kohler engines are everywhere. They are in:

- Lawn care equipment

- Construction machinery

- Power generators

- Pressure washers

Reliability And Performance

Kohler engines stand for strength. Users trust them for their:

| Feature | Benefit |

|---|---|

| Long-lasting build | Long-term use |

| Consistent power output | Smooth operation |

| Easy maintenance | Less downtime |

Credit: m.youtube.com

Common Kohler Engine Issues

When your Kohler engine is not running smoothly, it can be frustrating. Recognizing common problems can help you quickly get back to work. Here are some issues many owners face with their Kohler engines:

Starting Difficulties

- Dead Battery: Check voltage with a multimeter.

- Fuel Issues: Ensure fresh fuel is in the tank.

- Dirty Air Filter: Clean or replace the filter.

- Spark Plug Problems: Inspect and clean or change spark plugs.

- Stale Fuel: Replace old fuel with fresh gasoline.

- Choke Malfunction: Verify the choke is engaging properly.

Irregular Engine Performance

- Dirty Carburetor: Clean the carburetor carefully.

- Fuel Mixture: Adjust the mixture for optimal performance.

- Airflow Blockages: Remove any obstructions from air intakes.

- Loose Connections: Tighten all nuts and bolts.

- Worn Belts: Inspect belts for wear and replace if needed.

- Ignition Timing: Check and adjust the ignition timing.

Fuel System Diagnostics

Let’s dive into Fuel System Diagnostics for your Kohler Engine. This guide helps spot common fuel system issues. Knowing these can save time and money.

Clogged Fuel Filters

Clogged fuel filters are a big problem. They block fuel flow. This makes engines run poorly or not start. Here’s how to fix it:

- Check the filter for dirt or blockage.

- Replace the filter if it’s dirty.

- Always use Kohler-approved filters for best results.

Fuel Pump Failures

Fuel pumps move fuel from the tank to the engine. A bad pump means no fuel gets to the engine. Signs of a failing pump include:

- Engine sputters at high speeds.

- Power loss while under stress.

- Engine does not start at all.

To fix, inspect the pump for damage. Test it with a gauge. Replace if needed.

| Issue | Symptom | Action |

|---|---|---|

| Clogged Filter | Poor engine performance | Replace filter |

| Fuel Pump Failure | Engine does not start | Inspect and replace pump |

Remember, regular checks and maintenance prevent fuel system problems. Keep your Kohler engine running smoothly with these tips.

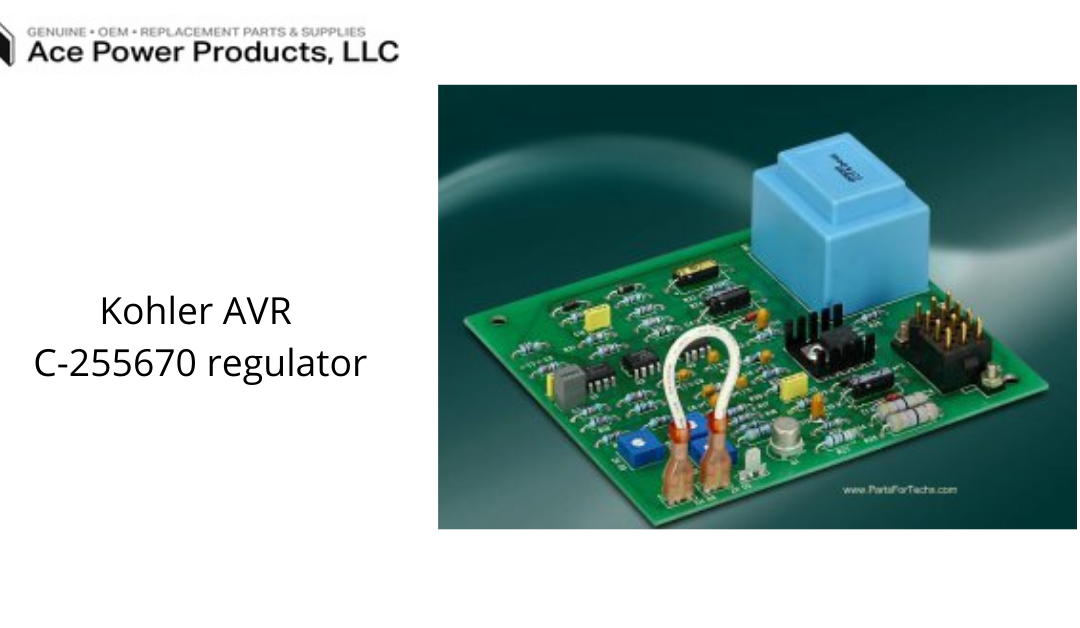

Credit: acepowerproducts.us

Electrical System Checks

Is your Kohler engine not starting? The culprit could be the electrical system. Let’s troubleshoot it step by step.

Battery Concerns

Check the battery first. A weak or dead battery can’t start an engine. Use a multimeter to test the voltage. A healthy battery should read close to 12.6 volts. If it’s below 12.4 volts, charge it. Loose or corroded terminals also cause trouble. Clean and tighten them for a good connection.

Faulty Spark Plugs

Spark plugs ignite the fuel. A bad spark plug stops this. Remove the plug and inspect it. Look for soot, damage, or wear. Use a spark plug tester to check for a strong spark. Replace the plug if it’s faulty. Remember to set the right gap on new plugs.

Regular maintenance prevents these issues. Replace spark plugs and charge the battery as needed. This keeps your Kohler engine ready to work.

Air Intake And Filtration

Every Kohler engine relies on clean air for efficient operation. The air intake and filtration system is crucial. It ensures that your engine breathes easily. A well-maintained system boosts performance and extends engine life. Let’s dive into keeping your Kohler engine’s air intake and filtration system in top shape.

Air Filter Maintenance

A clean air filter is essential for engine health. It traps dirt and debris before they reach the engine. Over time, filters become clogged and need attention. Follow these steps for regular maintenance:

- Check the air filter every 25 hours of use.

- Clean the filter with a mild detergent if it’s dirty.

- Replace the filter every 100 hours or annually, whichever comes first.

Always use genuine Kohler filters for the best fit and function.

Problems With Air Flow

Issues with air flow can cause engine performance to suffer. Look out for these signs:

| Sign | Possible Cause | Action |

|---|---|---|

| Power Loss | Clogged air filter | Clean or replace the filter. |

| Hard Start | Blocked air intake | Inspect and clear the air intake path. |

| Excessive Smoke | Dirty filter | Check and service the air filter. |

Remember to keep the area around the air intake clear. Ensure all connections are secure for optimal engine performance.

Oil System Management

Maintaining your Kohler engine starts with Oil System Management. A healthy oil system ensures your engine runs smoothly and lasts longer. Let’s dive into how to keep your oil system in top shape.

Oil Level And Quality

Checking the oil level and quality is key. Do this regularly. Use the dipstick to check oil levels. Make sure the engine is off and cool. Wipe the dipstick clean, insert it, then pull it out to check the level. The oil should be between the marks. Change the oil if it’s dirty or low. Follow the manufacturer’s recommendations for oil type and change intervals.

- Check oil level with the dipstick.

- Engine should be cool and off.

- Change oil if dirty or low.

- Use recommended oil type.

Leaks And Contamination

Leaks can damage your engine. Look for oil spots under the engine. Tighten any loose parts you find. Replace damaged seals or gaskets. Contamination hurts engine parts. Keep the area around the oil fill cap clean. Check for water or debris in the oil. Change the oil if you find any contamination.

| Action | Reason |

|---|---|

| Check for leaks. | Prevents engine damage. |

| Tighten loose parts. | Stops oil from leaking. |

| Replace seals/gaskets. | Keeps oil inside the engine. |

| Keep oil fill area clean. | Prevents contamination. |

| Change oil if contaminated. | Protects engine parts. |

Cooling System Troubleshooting

Maintaining a Kohler engine’s cooling system is vital for performance. This section covers common cooling system issues and how to fix them. Keep your engine running smoothly by addressing these problems promptly.

Overheating Issues

Overheating can damage your Kohler engine. Signs include power loss and steam. Here’s how to troubleshoot:

- Check the airflow: Ensure nothing blocks the air intake.

- Examine the thermostat: It might need replacement.

- Inspect the fan: Look for damage or debris.

Radiator And Coolant Inspection

Regular checks on the radiator and coolant prevent overheating. Follow these steps:

- Inspect the radiator for leaks or blockages.

- Ensure coolant levels are correct.

- Check for coolant color changes or contamination.

Clean the radiator regularly for optimal performance. Replace the coolant as per the manufacturer’s guidelines.

Mechanical Components And Wear

Mechanical components in Kohler engines ensure smooth operations. Over time, these parts may wear down. Understanding common issues with valves and camshaft timing is crucial. Replacing worn-out parts is often necessary to maintain engine performance.

Valves And Camshaft Timing

Properly functioning valves are key for engine efficiency. They control air and fuel flow. Timing with the camshaft is critical. Here’s how to check and adjust them:

- Inspect valve conditions regularly.

- Listen for unusual noises.

- Check timing with a timing light tool.

- Adjust as per the manufacturer’s guide.

Worn Out Parts Replacement

Engines suffer from worn components over time. Replacing these parts can restore performance. Here’s a list of commonly replaced parts:

| Part | Sign of Wear | Action |

|---|---|---|

| Spark plugs | Misfiring engine | Replace |

| Air filters | Decreased airflow | Replace |

| Belts | Cracks or frays | Replace |

Always use genuine Kohler parts for replacements.

Carburetor And Governor Adjustments

Smooth engine performance hinges on precise carburetor and governor tuning. These components regulate fuel and engine speed. Proper adjustments ensure peak efficiency and longevity. We’ll guide you through carburetor tuning and governor setup. Follow these steps to optimize your Kohler engine’s function.

Carburetor Tuning

Correct carburetor tuning boosts engine power and fuel economy. Begin with a clean carburetor. Inspect for clogs or damage. Adjust the idle and main mixture screws. Here’s a simplified tuning process:

- Start the engine and let it warm up.

- Turn the idle mixture screw for optimal idle.

- Adjust the main mixture for peak performance.

- Recheck idle after main adjustment.

Small tweaks can make big differences. Use a tachometer for precision. Ensure a balance between fuel and air. This balance is crucial for smooth operation.

Governor Set-up

The governor maintains engine speed under varied loads. An improperly set governor can cause speed instability. Here’s a basic governor adjustment guide:

- Locate the governor arm and linkage.

- Loosen the governor arm clamp.

- Move the throttle to the full open position.

- Rotate the governor shaft clockwise fully.

- Tighten the clamp while holding the shaft.

- Start the engine and test the governor response.

Ensure the governor responds to load changes. Adjustments should result in steady RPMs. Recheck the carburetor settings after governor adjustments.

Both systems work together. Proper setup ensures peak engine performance. Follow the manufacturer’s manual for specific details. Regular maintenance keeps your Kohler engine in top shape.

Preventive Maintenance Strategies

Keeping your Kohler engine in top shape is key. A well-maintained engine runs better and lasts longer. Let’s dive into the best strategies for keeping your Kohler engine at its peak.

Regular Service Schedule

Maintenance is not just a fix but a routine. Follow a service schedule to keep your engine happy. Here’s what you should do:

- Check the oil every 8 hours of use.

- Change the oil after the first 5 hours. Then, every 50 hours or once a season.

- Replace spark plugs and air filters annually.

- Inspect the fuel system for leaks or damage regularly.

Long-term Engine Care Tips

For the engine’s lifespan, follow these tips:

- Store your engine in a clean, dry place.

- Use fresh, high-quality fuel.

- Run the engine every few weeks if not used regularly.

- Keep the cooling fins clear of debris.

Remember, consistency in care ensures longevity and reliability. Stick to these strategies, and your Kohler engine will thank you.

Professional Repair Vs. Diy

Dealing with a faulty Kohler engine can be a headache. Sometimes, it’s tough to decide between a professional repair or a DIY fix. Understanding the limits of DIY and when to call in experts saves time and money.

When To Seek Professional Help

- Complex Issues: If the engine has internal damage, a skilled technician should handle it.

- Warranty Concerns: DIY repairs might void warranties. Check your engine’s warranty before starting.

- Lack of Tools: Some repairs require special tools. Without them, seek professional service.

- Safety Risks: When unsure about the safety of a repair, call a professional. Safety comes first.

Diy Troubleshooting Tips

- Read the Manual: Always start with the Kohler engine manual. It gives specific troubleshooting steps.

- Check the Basics: Verify fuel, oil, and air filters. Simple checks often solve common problems.

- Inspect Spark Plugs: A dirty spark plug can stop an engine. Remove and clean it for a quick fix.

- Battery Care: Dead batteries are common issues. Charge or replace as needed.

Remember, regular maintenance prevents many problems. Tackle simple tasks at home and leave complex issues to experts.

Credit: engines.kohlerenergy.com

Troubleshooting Resources

Having trouble with your Kohler engine? You’re not alone. Many people face issues with their engines. But don’t worry. There are many resources to help you fix the problems. This guide points you to the best troubleshooting resources available.

Manuals And Guides

Start with the basics. Manuals and guides are your best friends. They offer step-by-step instructions for fixing common issues. Find them easily on the Kohler website. Look for your engine model and download the guide. This should be your first step in troubleshooting.

- Identify your engine model

- Download the right manual

- Follow step-by-step troubleshooting instructions

Online Forums And Support

Online forums are treasure troves of information. Other Kohler engine owners share their experiences and solutions. You can find answers to your specific problems. Sometimes, you learn about fixes you never considered. Remember, it’s always good to share your solutions too. This helps the community grow stronger.

- Search for your engine problem

- Read through various solutions

- Ask questions if you need more help

- Share your own experiences and fixes

Frequently Asked Questions

Why Does My Kohler Engine Not Start?

A Kohler engine might not start due to a variety of reasons such as a faulty spark plug, clogged fuel filter, or a dead battery. Ensure that the fuel valve is open, the air filter is clean, and the carburetor is free of debris.

How Do You Fix A Kohler Engine That Stalls?

To fix a stalling Kohler engine, check the fuel quality and replace it if it’s stale. Also, clean or replace the air filter, adjust the carburetor settings, and ensure the spark plug is functioning properly.

What Are Common Kohler Engine Oil Problems?

Common oil issues in Kohler engines include low oil levels, incorrect oil viscosity, and oil leaks. Regular checks and timely oil changes with the right type of oil are crucial for engine health.

Can A Dirty Carburetor Affect My Kohler Engine?

Yes, a dirty carburetor can affect your Kohler engine by disrupting the fuel and air mixture, leading to hard starting, rough running, or stalling. Cleaning the carburetor can resolve these issues.

How To Troubleshoot Kohler Engine Overheating?

Troubleshoot overheating by checking for a dirty air filter, blocked cooling fins, low engine oil, or a malfunctioning ignition system. Clear any debris and ensure proper airflow to prevent overheating.

What Causes Kohler Engine Backfire?

Backfiring in Kohler engines is often caused by an improperly adjusted carburetor, a faulty ignition system, or the engine running too lean. Ensuring proper fuel mixture and spark plug function can mitigate backfiring.

Conclusion

Navigating Kohler engine issues can be daunting, but with the right approach, it’s manageable. This guide provides the insights needed to identify and fix common problems effectively. Remember, regular maintenance is key to engine longevity. For more complex issues, always consult a professional.

Keep your Kohler engine running smoothly with our expert tips and tricks.