IPS (“Iron Pipe Straight”) and NPT (National Pipe Taper) threads are not compatible with each other. IPS threads are designed to seal on a washer, while NPT threads are tapered and seal on the threads themselves.

This difference in design requires different sealing methods, with IPS threads using washers and NPT threads using pipe tape to lubricate and deform the threads for a tight seal. It is important to identify the type of thread being used to ensure proper compatibility and sealing.

Introduction To Ips And Npt Threads

When it comes to plumbing and fittings, understanding the differences between IPS and NPT threads is crucial. Both IPS (Iron Pipe Straight) and NPT (National Pipe Taper) threads are widely used in various applications, and knowing their basics can help in selecting the right fittings for specific requirements.

The Basics Of Ips Threads

IPS (Iron Pipe Straight) threads, also known as NPS (Nominal Pipe Size) threads, are straight threads that require a gasket or washer for sealing. These threads are not interchangeable with NPT threads due to their different sealing mechanisms. IPS threads are commonly used in applications where a watertight seal is essential, such as water supply lines and certain types of fittings.

The Fundamentals Of Npt Threads

NPT (National Pipe Taper) threads are tapered threads that create a tight seal through the deformation of the threads when tightened. They are commonly used in plumbing and piping systems for a secure and leak-resistant connection. NPT threads are not compatible with IPS threads due to their distinct design and sealing method.

Credit: www.buyfittingsonline.com

Historical Development

The development of IPS and NPT threads has a rich historical background, with each standard evolving to meet specific industrial needs. Understanding the origins and evolution of these standards is crucial for comprehending their significance in modern applications.

Origins Of Ips Standard

The IPS standard, which stands for Iron Pipe Size, traces its origins back to the early 20th century. It was established as a standardized system for sizing and regulating iron pipes in the United States. This standardization aimed to streamline the manufacturing and installation processes, ensuring compatibility and consistency across various industrial applications.

Evolution Of Npt Standard

On the other hand, the NPT standard, or National Pipe Taper, has its roots in the late 19th century. It was developed to address the need for a reliable and leak-resistant threading system for pipes and fittings. The evolution of NPT standard involved meticulous refinements in taper angles and thread profiles to enhance sealing capabilities and structural integrity.

Physical Characteristics

The IPS (“Iron Pipe Straight”) thread is equivalent to NPS, but not really compatible with NPT. The NPT is a tapered thread designed to seal on the threads, whereas IPS is meant to seal on a washer. When connecting IPS to NPT, it’s important to consider the compatibility of the threading standards.

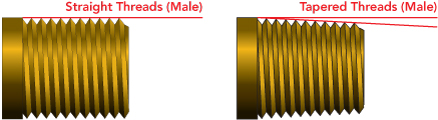

Thread Shape And Design

When comparing IPS (Iron Pipe Straight) and NPT (National Pipe Taper) threads, one of the key differences lies in their thread shape and design. IPS threads are straight threads, while NPT threads are tapered. This means that IPS threads have a constant diameter throughout the entire length of the thread, while NPT threads gradually decrease in diameter towards the end. The tapered design of NPT threads allows for a tighter and more secure connection, ensuring a reliable seal. On the other hand, IPS threads are typically used in applications where a washer or gasket is used to create a seal.

Diameter And Pitch Variations

Another important aspect to consider when comparing IPS and NPT threads is the variations in diameter and pitch. IPS threads are available in a range of standard sizes, with consistent diameters and pitch throughout. NPT threads, on the other hand, have variations in both diameter and pitch. The diameter of NPT threads decreases gradually, while the pitch remains constant. This variation in diameter allows for a tighter fit when connecting two NPT threaded components.

It is important to note that IPS and NPT threads are not directly compatible with each other. While IPS threads can be used in certain applications where a washer or gasket is used for sealing, NPT threads are specifically designed to create a tight and reliable seal through their tapered design. Therefore, it is crucial to ensure that the correct thread type is used for each specific application to avoid any potential issues with leaks or improper connections.

In conclusion, the physical characteristics of IPS and NPT threads differ in terms of thread shape and design, as well as variations in diameter and pitch. Understanding these differences is essential for selecting the appropriate thread type for your specific application and ensuring a secure and leak-free connection.

Sealing Mechanisms

IPS (“Iron Pipe Straight”) threads are not compatible with NPT threads. IPS threads are meant to seal on a washer, while NPT threads are tapered to seal on the threads themselves. It’s important to identify the correct thread type to ensure a proper seal and prevent leaks.

How Ips Threads Achieve A Seal

IPS (Iron Pipe Straight) threads are designed to achieve a seal by using a washer. These threads are commonly found in applications such as toilet hoses and faucet attachments. Unlike NPT (National Pipe Taper) threads, IPS threads are straight and do not taper. The straight design allows for a secure seal when the washer is compressed against the connection point.

Npt Threads And Their Sealing Technique

NPT (National Pipe Taper) threads have a tapered design, which allows them to create a seal by tightening the threads. When connecting two NPT threaded fittings, a seal is achieved by the threads deforming and compressing against each other. To further enhance the sealing capability of NPT threads, pipe tape is often applied to lubricate the threads and help prevent leaks.

In summary, IPS threads achieve a seal by using a washer, while NPT threads rely on the taper and deformation of the threads themselves to create a tight seal. Both types of threads have their advantages and are used in different applications depending on the specific sealing requirements.

Applications And Uses

NPT (National Pipe Taper) threads and IPS (Iron Pipe Straight) threads are different types of pipe threads. While IPS threads are meant to seal on a washer, NPT threads are tapered and designed to seal on the threads themselves. Therefore, IPS and NPT threads are not compatible with each other.

Common Ips Thread Applications

IPS, or Iron Pipe Straight, is a thread standard used in North America for pipes and fittings. Common applications for IPS threads include plumbing, irrigation, and gas distribution systems. These threads are typically used in situations where a tight seal is required.

Typical Uses For Npt Threads

NPT, or National Pipe Thread, is a tapered thread used in North America for pipes and fittings. NPT threads are typically used in low-pressure applications such as water and air lines, as well as in the petroleum industry. These threads are also commonly used in plumbing and heating systems.

When it comes to compatibility, IPS threads are not really compatible with NPT threads. While IPS is equivalent to NPS (National Pipe Straight), NPT is a tapered thread designed to seal on the threads, which is why pipe tape is used to lubricate and help the threads deform to create a tight seal.

Overall, the choice between IPS and NPT threads depends on the specific application and the type of pipe or fitting being used. While both are widely used in North America, it’s important to understand their differences and select the appropriate thread standard for your particular needs.

Credit: ambassadorfaucets.com

Compatibility Concerns

When it comes to compatibility concerns between IPS and NPT threads, it’s important to understand the key differences. IPS (Iron Pipe Straight) threads are not really compatible with NPT (National Pipe Taper) threads. While IPS is meant to seal on a washer, NPT is a tapered thread designed to seal on the threads themselves.

Therefore, it’s crucial to ensure the correct thread type for a proper fit.

Interchangeability Between Ips And Npt

When it comes to compatibility concerns between IPS and NPT threads, it’s important to understand the key differences between the two. IPS (Iron Pipe Straight) threads are equivalent to NPS (National Pipe Straight) threads, but they are not compatible with NPT (National Pipe Tapered) threads. This is because IPS threads are designed to seal on a washer, while NPT threads are tapered and designed to seal on the threads themselves. To ensure a proper seal, it’s important to use the correct thread type for your application.

Adapters And Fittings

If you need to connect IPS and NPT threads, adapters and fittings are available to make the connection. However, it’s important to use the correct adapter or fitting to ensure a proper seal. Adapters and fittings are available in both IPS-to-NPT and NPT-to-IPS configurations, so be sure to select the appropriate type for your application. Using the wrong adapter or fitting can result in leaks and other issues.

Code Example

// Example of connecting IPS to NPT with an adapter

var ipsThread = "1 inch IPS";

var nptThread = "1/2 inch NPT";

var adapter = new IpsToNptAdapter();

var connection = adapter.connect(ipsThread, nptThread);

While IPS and NPT threads are not directly compatible, adapters and fittings can be used to make the connection. It’s important to use the correct thread type and adapter or fitting to ensure a proper seal and avoid leaks and other issues. With the right components and proper installation, you can connect IPS and NPT threads for your specific application.

Installation Best Practices

When it comes to installation best practices, it’s important to understand the difference between IPS and NPT threads. IPS (Iron Pipe Straight) is equivalent to NPS, but not really compatible with NPT (National Pipe Tapered) due to the tapered thread design.

Proper identification of thread types is essential to ensure a secure and leak-free installation.

Proper Handling Of Ips Threads

When it comes to installing IPS (Iron Pipe Straight) threads, it is important to follow proper handling practices to ensure a successful and leak-free installation. Here are some tips:

- Inspect the IPS threads for any signs of damage or debris. Clean the threads thoroughly before installation.

- Apply a suitable thread sealant or plumber’s tape to the male IPS threads. This will help create a tight seal and prevent leaks.

- Hand tighten the IPS fittings until they are snug. Avoid over-tightening, as it can damage the threads.

- Use a wrench or pliers to give the fittings a final quarter-turn to ensure a secure connection.

- If using IPS fittings with a washer, make sure the washer is in good condition and properly seated.

- After installation, check for any leaks by running water through the system and inspecting the connections.

Tips For Working With Npt Threads

NPT (National Pipe Taper) threads have a tapered design, which requires specific handling techniques for a successful installation. Here are some tips:

- Inspect the NPT threads for any signs of damage or debris. Clean the threads thoroughly before installation.

- Apply a suitable thread sealant, such as Teflon tape or pipe dope, to the male NPT threads. This will help create a tight seal and prevent leaks.

- Wrap the thread sealant in the direction of the thread rotation to ensure proper sealing.

- Hand tighten the NPT fittings until they are snug. Avoid over-tightening, as it can damage the threads.

- Use a wrench or pliers to give the fittings a final quarter-turn to ensure a secure connection.

- After installation, check for any leaks by running water through the system and inspecting the connections.

By following these installation best practices, you can ensure a successful and leak-free installation whether you are working with IPS or NPT threads.

Troubleshooting And Maintenance

When it comes to IPS (Iron Pipe Straight) and NPT (National Pipe Taper) threads, it’s important to understand the common issues that can arise with their connections. By being aware of these issues and implementing proper maintenance techniques, you can ensure the longevity and reliability of your plumbing system. In this section, we will discuss the common issues with IPS and NPT connections and provide some maintenance tips for their longevity.

Common Issues With Ips And Npt Connections

Both IPS and NPT connections can encounter problems that may lead to leaks or other plumbing issues. Here are some of the common issues you may face:

- Thread Compatibility: IPS and NPT threads are not compatible with each other. While IPS threads are designed to seal on a washer, NPT threads are tapered and require pipe tape to lubricate and create a seal on the threads.

- Leakage: Improper installation or damaged threads can lead to leakage at the connection points. It’s essential to ensure a tight and secure connection to prevent any leaks.

- Corrosion: Over time, both IPS and NPT connections can be susceptible to corrosion, especially in environments with high moisture or chemical exposure. Corrosion can weaken the connection, leading to leaks or complete failure.

Maintenance Tips For Longevity

To maintain the longevity of IPS and NPT connections, consider the following maintenance tips:

- Proper Installation: Ensure that the threads are clean and free from debris before making the connection. Use a suitable thread sealant, such as pipe tape or pipe dope, to create a tight and leak-free seal.

- Regular Inspection: Periodically check the connections for any signs of leakage, corrosion, or damage. If you notice any issues, address them promptly to prevent further damage.

- Corrosion Prevention: Apply an anti-corrosion coating or paint to the connections, especially if they are exposed to moisture or chemicals. This will help protect the threads and extend their lifespan.

- Proper Handling: Avoid overtightening the connections, as this can damage the threads. Use the appropriate tools and techniques to ensure a secure but not excessive tightening.

By following these maintenance tips, you can minimize the risk of issues with your IPS and NPT connections and promote their longevity. Regular inspection and proactive maintenance will help you catch and address any potential problems before they escalate into larger issues.

Regulatory And Standardization

When it comes to understanding the differences between IPS and NPT threads, one crucial aspect to consider is the regulatory and standardization perspective. Industry standards play a significant role in determining the compatibility, functionality, and compliance of these thread types.

Industry Standards For Ips

IPS, which stands for Iron Pipe Straight, is a standardized thread type commonly used in the plumbing and irrigation industries. The IPS thread is designed to create a seal using a washer, similar to the threads found on hoses for toilets or faucets. It is essential to adhere to industry standards when manufacturing and utilizing IPS threads to ensure compatibility and performance.

Npt Standards And Compliance

NPT, or National Pipe Taper, is another widely utilized thread type, known for its tapered design and ability to create a seal through thread deformation. It is important to note that NPT threads are sometimes referred to as MIP (Male Iron Pipe), FIP (Female Iron Pipe), or IPT (Iron Pipe Thread). These variations fall under the NPT standards and must comply with industry regulations to maintain compatibility and functionality.

Credit: www.amazon.sa

Future Of Thread Standards

The development and evolution of thread standards play a crucial role in various industries, impacting the compatibility and efficiency of pipe fittings and connections. As technology advances, the future of thread standards is continually evolving to meet the changing needs of industries and applications. In this context, understanding the innovations and trends in threading technology, particularly in IPS and NPT threads, becomes essential for businesses and professionals in the field.

Innovations In Threading Technology

The innovations in threading technology are revolutionizing the way pipe fittings and connections are designed and utilized. Advanced manufacturing processes and materials are enabling the development of threads with enhanced durability, corrosion resistance, and precision. Innovations such as composite materials, coatings, and advanced machining techniques are redefining the performance and longevity of threaded connections, addressing the challenges posed by harsh environments and demanding applications.

Trends In Ips And Npt Usage

The usage of IPS and NPT threads continues to reflect the evolving needs of industries and applications. While NPT threads are widely used in the plumbing and hydraulic systems, IPS threads find applications in irrigation and fire protection systems, among others. Trends indicate a growing demand for standardized interchangeability and compatibility, driving the development of hybrid fittings and adapters to facilitate seamless transitions between different thread standards.

Frequently Asked Questions

Is Ips Thread Compatible With Npt?

IPS (“Iron Pipe Straight”) thread is not really compatible with NPT (“National Pipe Taper”) thread. IPS is designed to seal on a washer, while NPT is a tapered thread meant to seal on the threads.

Is 1/2 Npt The Same As 1/2 Ips?

Yes, 1/2 NPT and 1/2 IPS are not the same. NPT stands for National Pipe Tapered, while IPS stands for Iron Pipe Straight.

Is Npt The Same As Ipt?

NPT and IPT are not the same. NPT stands for National Pipe Taper, while IPT refers to Iron Pipe Thread.

What Is The Difference Between Ips And Pipe Thread?

IPS (Iron Pipe Straight) thread is designed to seal on a washer, like the threads on a hose for your toilet or faucets. On the other hand, NPT (National Pipe Taper) thread is tapered and designed to seal on the threads themselves.

This is why pipe tape is used on NPT threads to lubricate them and create a seal. IPS and NPT threads are not compatible with each other.

What Is The Difference Between Npt And Ips Threads?

NPT threads are tapered and designed to seal on the threads, while IPS threads are straight and seal on a washer.

Conclusion

Understanding the difference between IPS and NPT threads is crucial for any plumbing or industrial project. While IPS threads are straight and meant to seal on a washer, NPT threads are tapered and designed to seal on the threads themselves.

It’s important to note that these two types of threads are not compatible with each other, so it’s essential to select the right thread type for your specific project. By keeping this in mind, you can ensure that your project is successful and meets all necessary standards.