Hunter solenoid valves are essential for irrigation systems. They control water flow efficiently.

Troubleshooting these valves can seem tricky but can save you time and money. Understanding common issues and their solutions is key. Problems like a valve not opening, leaking, or inconsistent water pressure can disrupt irrigation. Identifying the root cause helps in fixing these problems swiftly.

This guide will walk you through the basic steps of troubleshooting Hunter solenoid valves. With clear instructions, you can resolve issues yourself. This not only ensures your irrigation system runs smoothly but also extends the life of your valves. Let’s dive into the essentials of Hunter solenoid valve troubleshooting and keep your irrigation system in top shape.

Credit: www.hillsirrigation.com.au

Introduction To Solenoid Valves

Solenoid valves play a crucial role in modern irrigation systems. They are the key components that control the flow of water, making sure your plants get the right amount of hydration. Understanding how these valves work can help you maintain an efficient irrigation system and troubleshoot issues when they arise.

What Are Solenoid Valves?

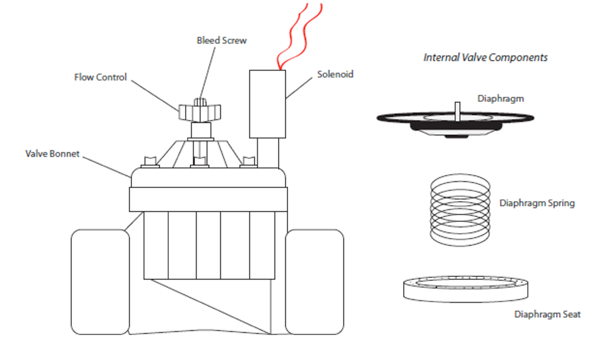

A solenoid valve is an electromechanical device. It controls the flow of liquids or gases. The valve is usually controlled by an electric current through a solenoid. When the current flows, the valve opens or closes. This allows for precise control of fluid flow. They are widely used in various applications due to their reliability and efficiency.

Importance In Irrigation Systems

In irrigation systems, solenoid valves regulate water distribution. They ensure that each area of your garden gets the right amount of water. This is vital for plant health and water conservation. Solenoid valves are often connected to a timer or controller. This setup automates the watering process, making it easier and more efficient. If a solenoid valve fails, it can disrupt the entire system. Thus, proper maintenance and troubleshooting are essential.

Common Issues

When dealing with Hunter solenoid valves, several common issues may arise. Understanding these problems can help in maintaining and troubleshooting your irrigation system effectively. Below are some of the most frequent issues and their solutions.

Valve Not Opening

If a Hunter solenoid valve is not opening, it can disrupt the entire irrigation system. Here are some possible causes and solutions:

- Power Supply Issues: Check if the power supply is consistent. Ensure the controller is functioning and sending power to the valve.

- Faulty Solenoid: The solenoid might be defective. Test it with a multimeter to ensure it is receiving power. Replace if necessary.

- Clogged Diaphragm: Debris can clog the diaphragm, preventing the valve from opening. Clean the diaphragm to remove any blockages.

Valve Not Closing

A Hunter solenoid valve that won’t close can lead to water wastage and damage. Below are potential causes and fixes:

- Debris in Valve: Dirt or debris can keep the valve from closing completely. Clean the valve and ensure all parts move freely.

- Damaged Diaphragm: A worn or damaged diaphragm can cause the valve to stay open. Inspect and replace the diaphragm if necessary.

- Electrical Issues: Faulty wiring or a defective solenoid can prevent the valve from closing. Check wiring connections and test the solenoid.

| Issue | Possible Cause | Solution |

|---|---|---|

| Valve Not Opening | Power Supply, Faulty Solenoid, Clogged Diaphragm | Check power, Replace solenoid, Clean diaphragm |

| Valve Not Closing | Debris, Damaged Diaphragm, Electrical Issues | Clean valve, Replace diaphragm, Check wiring |

Initial Checks

When troubleshooting a Hunter solenoid valve, start with the initial checks. These steps help identify basic issues before moving to more complex diagnostics. Simple checks can save time and effort.

Power Supply Inspection

First, check the power supply. Ensure the system has power. Verify if the controller is plugged in and turned on. Use a multimeter to check the voltage. The voltage should match the solenoid’s requirements. If there’s no power, the solenoid won’t work.

Wiring And Connections

Next, inspect the wiring and connections. Look for loose or disconnected wires. Ensure all connections are secure. Check for any signs of damage to the wires. Damaged wires may cause a short circuit. Use a multimeter to test the continuity. A broken wire needs replacement.

Credit: www.hunterindustries.com

Testing The Solenoid

Testing the solenoid in your Hunter valve is vital for irrigation maintenance. A malfunctioning solenoid can disrupt your entire system. This section will guide you through testing the solenoid, ensuring your irrigation runs smoothly.

Using A Multimeter

A multimeter is a useful tool for testing solenoids. First, set your multimeter to the ohms setting. This measures resistance.

Disconnect the solenoid wires from the controller. Place the multimeter probes on the solenoid terminals. A healthy solenoid should read between 20 to 60 ohms.

If the reading is outside this range, the solenoid might be defective. Replace it if necessary to restore proper function.

Manual Activation

Manual activation helps determine if the solenoid operates correctly. Turn the solenoid’s bleed screw slightly to activate it manually.

Water should flow through the valve when the bleed screw is open. Turn the screw back to its original position to stop the water flow.

If there is no water flow, the solenoid may need replacement. Ensure the valve has water pressure before concluding the solenoid is faulty.

Cleaning The Valve

Cleaning the Hunter solenoid valve helps fix common irrigation problems. Remove debris and ensure water flows smoothly. Regular maintenance keeps the valve functioning properly.

Cleaning a Hunter solenoid valve ensures it works correctly. Over time, dirt and debris can block the valve. This can cause issues with water flow. Regular cleaning keeps the valve in good condition.

Removing Debris

First, turn off the water supply. Then, locate the valve. Use a wrench to open the valve. Carefully remove any visible debris. Use a small brush to clean the valve seat. Inspect the valve for any damaged parts.

Cleaning Techniques

Soak the valve in a mixture of water and mild detergent. Use a soft brush to scrub away any grime. Rinse the valve with clean water. Dry it thoroughly before reassembling. Ensure all parts are clean and free of debris. This helps maintain optimal performance.

“`

Credit: www.youtube.com

Replacing The Solenoid

Replacing the solenoid in a Hunter valve is a common task. This guide will help you through the process. It covers identifying the right replacement and a step-by-step guide.

Identifying The Right Replacement

First, know your Hunter valve model. Check the manual or the valve itself. Find the solenoid part number. This ensures compatibility. Order the correct solenoid from a trusted supplier. The right part avoids future issues.

Step-by-step Replacement Guide

Gather your tools: a screwdriver and pliers. Turn off the water supply. This prevents water from flowing during the replacement. Locate the solenoid on the valve. It is usually black and has wires attached.

Unscrew the old solenoid. Use the pliers if it is tight. Disconnect the wires carefully. Take note of their positions. Remove the old solenoid completely. Install the new solenoid by screwing it in place. Reconnect the wires as they were.

Turn on the water supply. Test the valve to ensure it works. Check for leaks around the new solenoid. Tighten it if necessary. Your valve should now function properly.

Preventive Maintenance

Preventive maintenance is crucial for ensuring the long-term functionality of your Hunter solenoid valve. It helps in identifying potential problems before they escalate. By following a structured maintenance plan, you can extend the life of your valve and ensure it operates efficiently.

Regular Inspection Schedule

Establishing a regular inspection schedule is essential. Make it a habit to check your valve at least once a month. During these inspections, focus on the following aspects:

- Check for any visible signs of wear or damage.

- Ensure that all connections are secure and not corroded.

- Look for any leaks or unusual noises when the valve is in operation.

Use a checklist to ensure nothing is overlooked:

| Inspection Point | Frequency | Notes |

|---|---|---|

| Visual damage check | Monthly | Look for cracks or wear. |

| Connection security | Monthly | Ensure all fittings are tight. |

| Leak detection | Monthly | Check for moisture around the valve. |

Proper Storage

Proper storage of your Hunter solenoid valve is important to prevent damage. If the valve is not in use, follow these storage tips:

- Store in a dry, cool place to avoid rust and corrosion.

- Keep the valve in its original packaging to protect it from dust and debris.

- Avoid placing heavy objects on top of the valve to prevent physical damage.

These steps will help maintain the integrity of the valve and ensure it is ready for use when needed.

Expert Tips

Hunter solenoid valves are essential components in irrigation systems. Understanding how to troubleshoot them can prevent common issues and ensure your system operates smoothly. In this section, we provide expert tips to help you maintain and repair your Hunter solenoid valves effectively.

Best Practices

Regular maintenance ensures your solenoid valves work efficiently. Inspect the valves monthly for any signs of wear or damage. Clean the valve and its components to remove dirt and debris. Make sure the wiring is intact and free of corrosion. Test the solenoid by manually activating it to check for proper function. Use a multimeter to measure the electrical resistance of the solenoid coil. The reading should match the manufacturer’s specifications.

Common Mistakes To Avoid

Avoid ignoring minor leaks. They can turn into bigger problems. Do not use the wrong tools for repairs. This can damage the valve. Never bypass the manufacturer’s guidelines. This can lead to system failures. Avoid neglecting regular inspections. They help catch issues early. Do not assume all solenoid valves are the same. Each model may have different requirements. Avoid using non-compatible parts. They can cause malfunctions and void warranties.

Frequently Asked Questions

How Do I Know If My Solenoid Valve Is Faulty?

A faulty solenoid valve may not open or close properly. Check for unusual noises or leaks.

What Causes A Solenoid Valve To Fail?

Common causes include electrical issues, debris blocking the valve, or worn-out parts. Regular maintenance helps prevent failure.

How Can I Test A Solenoid Valve?

Use a multimeter to check for continuity. No continuity means the solenoid coil is bad.

Why Is My Solenoid Valve Making A Buzzing Noise?

A buzzing noise often indicates electrical problems or dirt in the valve. Clean and check electrical connections.

How Do I Clean A Solenoid Valve?

Turn off the power and water supply. Disassemble the valve, clean all parts, and reassemble carefully.

Conclusion

Troubleshooting a Hunter solenoid valve can be straightforward with the right steps. Check connections and clean debris. Test the solenoid with a multimeter. Replace faulty parts if needed. Regular maintenance prevents future issues. Understanding these basics ensures your irrigation system runs smoothly.

Always consult the manual for specific guidance. Happy gardening!