Hunter PGV valves are crucial for efficient irrigation. Yet, issues can arise.

Understanding how to troubleshoot Hunter PGV valve problems can save time and money. These valves control water flow in irrigation systems, and when they malfunction, your lawn or garden might suffer. Common issues include leaks, failure to open or close, and inconsistent water flow.

Knowing how to diagnose and fix these problems ensures your irrigation system runs smoothly. This guide will help you identify and solve common Hunter PGV valve issues, keeping your landscape healthy and vibrant. Let’s dive into troubleshooting steps to get your system back on track.

Common Issues

Hunter PGV valves are reliable, but they can face issues. Knowing common problems helps in quick fixes. This section covers the most frequent issues and their solutions.

Leaking Valve

Leaking valves are a common problem. Check for dirt in the valve. Clean the valve thoroughly. Inspect the valve seat for damage. Replace the seat if needed. Tighten all connections properly. Ensure the solenoid is not damaged. Replace the solenoid if it’s faulty.

No Water Flow

No water flow is a frustrating issue. First, check the water supply. Ensure the main valve is open. Inspect the filter for clogs. Clean or replace the filter if dirty. Check the solenoid for a secure connection. Test the wiring for any faults. Replace damaged wires immediately. Make sure the controller settings are correct.

Essential Tools

Having the right tools is crucial for troubleshooting your Hunter PGV valve. The right equipment can make the process smoother and more efficient. This section covers the essential tools you need for the job. Let’s dive into the basic toolkit and specialized equipment required.

Basic Toolkit

Your basic toolkit should include a few essential items. A set of screwdrivers is necessary. Both flathead and Phillips screwdrivers will come in handy. You will also need a pair of pliers. These are useful for gripping and turning parts. A small adjustable wrench can help with tightening and loosening nuts and bolts. Don’t forget to have a flashlight. Proper lighting is key for seeing inside valves and pipes.

Specialized Equipment

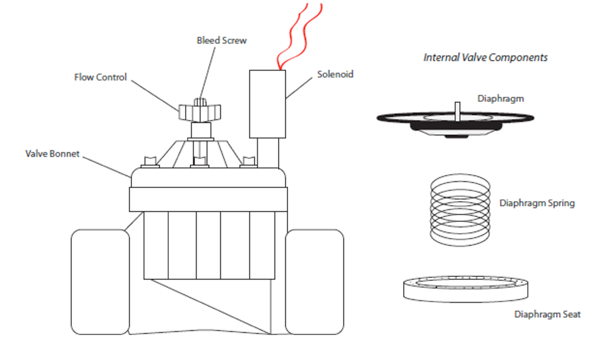

For more advanced troubleshooting, you might need specialized equipment. A multimeter is useful for checking electrical connections. This tool helps to ensure your valve’s solenoid is working correctly. A pressure gauge is another valuable tool. It helps monitor water pressure levels. A valve key can make it easier to open and close the valve. Finally, consider having a manual or guide specific to Hunter PGV valves. This can provide step-by-step instructions and diagrams.

Initial Checks

When addressing issues with your Hunter PGV valve, the first step is performing some initial checks. These checks help identify basic problems that might be affecting the valve’s performance. Let’s dive into the main areas you should examine.

Power Supply

Start by checking the power supply to ensure the valve is receiving electricity. Follow these steps:

- Verify the controller is plugged in and turned on.

- Inspect the wiring connections for any loose or damaged wires.

- Use a multimeter to check for voltage at the solenoid. It should read around 24 volts.

These steps ensure the valve has the necessary power to function.

Valve Settings

Next, examine the valve settings to confirm they are correct. This involves:

- Checking the manual bleed screw. Ensure it is tightened correctly.

- Inspecting the flow control adjustment. It should be set to the desired flow rate.

- Verifying the diaphragm is clean and seated properly.

Proper valve settings are crucial for optimal performance.

| Check | Action |

|---|---|

| Manual Bleed Screw | Tighten if loose |

| Flow Control | Adjust to desired rate |

| Diaphragm | Clean and seat properly |

These initial checks can resolve many common issues. They ensure your Hunter PGV valve operates effectively.

Credit: www.youtube.com

Cleaning The Valve

Keeping your Hunter PGV valve clean is crucial for its proper function. Dirt and debris can cause the valve to malfunction. Regular cleaning can prevent these issues. Below, we’ll discuss steps for removing debris and flushing the system.

Removing Debris

First, turn off the water supply. This prevents water flow while you work. Next, locate the screws on the valve cover. Use a screwdriver to remove them. Lift the cover carefully. Look inside the valve for any visible debris. Use a soft brush or cloth to remove dirt. Be gentle to avoid damaging internal parts. Check the diaphragm and other components for blockages.

Flushing The System

After removing debris, flush the system. Turn the water supply back on. Allow water to run through the valve for a few minutes. This clears out any remaining particles. Watch for any leaks or unusual noises. If everything looks good, turn off the water supply again. Reassemble the valve cover. Tighten the screws firmly but avoid over-tightening.

Replacing Components

Replacing components in a Hunter PGV valve can solve many issues. Two critical parts that often require replacement are the diaphragm and the solenoid. Understanding how to replace these parts will help keep your irrigation system running smoothly.

Diaphragm Replacement

First, turn off the water supply to the valve. Unscrew the bonnet from the valve body. Carefully remove the old diaphragm and inspect for damage. Clean the valve body to remove any debris. Place the new diaphragm into the valve body. Ensure it is seated correctly. Reattach the bonnet and tighten the screws evenly. Turn on the water supply and test the valve for leaks.

Solenoid Replacement

Shut off the water and power to the valve. Locate the solenoid on the valve. Unscrew the solenoid from the valve body. Disconnect the wires carefully. Attach the new solenoid by screwing it into place. Reconnect the wires. Turn the power and water back on. Test the valve to ensure proper operation.

Advanced Troubleshooting

In this section, we will dive deeper into advanced troubleshooting for your Hunter PGV valve. This guide will help you fix any complex issues that may arise. We will focus on two main areas: electrical testing and pressure testing. These steps will ensure your valve operates smoothly.

Electrical Testing

Electrical issues can disrupt the functioning of your Hunter PGV valve. Follow these steps to perform electrical testing:

- Turn off the power supply to the valve.

- Check the wiring connections for any loose or damaged wires.

- Use a multimeter to test the voltage at the valve solenoid. It should be between 24-28 volts AC.

- If the voltage is out of range, inspect the controller and wiring.

- Replace the solenoid if it shows no continuity.

Pressure Testing

Pressure problems can cause your valve to malfunction. Use these steps to conduct pressure testing:

- Shut off the main water supply.

- Attach a pressure gauge to the valve’s inlet.

- Turn the water supply back on and record the pressure reading.

- Compare the reading to the recommended pressure range for your valve model.

- If the pressure is too high or too low, adjust the water source or use a pressure regulator.

Regular maintenance and checks can prevent many common issues. Use these troubleshooting tips to keep your Hunter PGV valve in top shape.

Maintenance Tips

Maintaining your Hunter PGV valve ensures its longevity and optimal performance. Regular maintenance can prevent many common issues. Here are some essential tips to keep your valve in top shape.

Regular Inspections

Regular inspections are crucial for your Hunter PGV valve. Begin by checking for any visible damage or wear on the valve.

- Look for cracks, leaks, and signs of corrosion.

- Ensure the valve is securely connected and properly sealed.

- Inspect the wiring for any fraying or loose connections.

Use a checklist to ensure you cover all areas during your inspections:

| Inspection Area | What to Look For |

|---|---|

| Valve Body | Cracks, Leaks, Corrosion |

| Connections | Secure Fit, Proper Sealing |

| Wiring | Fraying, Loose Connections |

Seasonal Adjustments

Seasonal adjustments can extend the life of your Hunter PGV valve. Adjust your valve settings according to the season.

- Spring: Check for winter damage. Clean and test the valve.

- Summer: Increase water flow to meet higher demand.

- Fall: Reduce water flow as temperatures drop.

- Winter: Shut off water supply and drain the valve.

These adjustments help the valve cope with changing weather conditions.

Remember: A well-maintained Hunter PGV valve ensures your irrigation system operates smoothly. Regular inspections and seasonal adjustments are key.

Credit: www.hunterindustries.com

When To Call A Professional

Consider calling a professional if your Hunter PGV valve troubleshooting efforts fail. Persistent leaks, electrical issues, or complex repairs need expert attention. Ensuring proper function is crucial for an efficient irrigation system.

Troubleshooting your Hunter PGV valve can sometimes be straightforward. But there are times when professional help is needed. Knowing when to call an expert can save you time and prevent further issues.

Complex Issues

Some problems with Hunter PGV valves are not easy to diagnose. Electrical issues, for example, can be complicated. Incorrect wiring or voltage problems require specific tools and skills. If the valve does not respond to manual or automatic commands, this might indicate a deeper issue. Professionals have the experience to handle these situations.

Leaking valves can also be tricky. A small drip might seem minor. But it could signal a bigger problem inside the valve. A professional can identify and fix the root cause.

Preventive Services

Routine maintenance can prevent many valve issues. Professionals offer preventive services to keep your system running smoothly. They can inspect for wear and tear. They can also clean and test the valves. This ensures they work well and last longer. Regular check-ups can catch small problems before they become big ones.

A professional can also update your system. They can install new parts and make necessary adjustments. This keeps your irrigation system efficient and reliable.

“`

Credit: www.hunterindustries.com

Frequently Asked Questions

How Do I Know If My Hunter Pgv Valve Is Bad?

If your valve doesn’t open or close, it may be faulty. Check for leaks too.

Why Is My Hunter Pgv Valve Not Closing?

Debris in the valve can prevent closing. Clean the valve and check for blockages.

How Do You Fix A Leaking Hunter Pgv Valve?

Replace worn-out parts like the diaphragm or O-ring. Ensure all connections are tight.

What Causes A Hunter Pgv Valve To Stay Open?

A stuck solenoid or debris can cause this. Inspect and clean the valve components.

How Often Should I Maintain My Hunter Pgv Valve?

Inspect and clean your valve every 6-12 months. Regular maintenance ensures proper function.

Conclusion

Troubleshooting Hunter PGV valves can be simple. Start with basic checks. Clean any debris. Inspect connections and wiring. Replace faulty parts if needed. Regular maintenance prevents future issues. Keep your irrigation system running smoothly. Follow these tips for a hassle-free experience.

Your garden will thank you. Happy gardening!