To repair damaged plastic pipe threads, apply thread sealing tape or pipe dope to the male threads and screw the joint together until a seal is achieved. Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread’s damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

Additionally, mix up a small amount of JB Weld and lightly coat the screw with Vaseline. You can also tap the hole out bigger to give the Hysol/JB more “bite” before you insert the original sized screw. We will discuss different methods to repair damaged plastic pipe threads, such as using thread sealing tape, pipe dope, and JB Weld.

We will also explore how to fix stripped plastic and damaged threads on screws and bolts. Additionally, we will provide tips on how to fix a leaking threaded PVC joint without cutting.

Credit: m.youtube.com

Introduction To Plastic Pipe Thread Repair

When plastic pipe threads are damaged, it’s crucial to address the issue promptly to prevent leaks and ensure a secure connection. Repairing damaged plastic pipe threads requires careful assessment and the right techniques to restore the integrity of the threads.

Common Causes Of Thread Damage

- Over-tightening during installation

- Physical impact or stress on the pipe

- Exposure to harsh chemicals or extreme temperatures

Assessing The Extent Of Damage

Before initiating repairs, it’s essential to evaluate the extent of the thread damage. Look for signs of deformation, cracks, or stripping, and determine whether the damage is localized or extensive. This assessment will guide the appropriate repair method to be employed, ensuring a comprehensive restoration of the thread’s functionality.

Safety Precautions

Before attempting to repair damaged plastic pipe threads, it is crucial to prioritize safety precautions. By taking the necessary measures, you can protect yourself from potential hazards and ensure a smooth and secure repair process.

Protective Gear And Safe Practices

When repairing damaged plastic pipe threads, it is essential to wear the appropriate protective gear to safeguard yourself from potential harm. This includes wearing safety goggles to shield your eyes from debris and chemical exposure, as well as using gloves to protect your hands from sharp edges and hazardous substances.

Identifying Hazardous Substances

Prior to commencing the repair process, it is important to identify any hazardous substances that may be present in the vicinity. This may include checking for the presence of corrosive chemicals or toxins that could pose a risk to your health. Ensure that you are aware of the potential dangers and take appropriate measures to mitigate any associated risks.

Essential Tools And Materials

Repairing damaged plastic pipe threads requires a few essential tools and materials to ensure a successful fix. By having the right equipment and supplies on hand, you can quickly and effectively repair the damaged threads. Here are the key tools and materials you will need:

List Of Required Tools:

- Adjustable wrench

- Pipe threader

- Pipe cutter

- Hacksaw

- PVC solvent cement

- Thread sealant

- Plumber’s tape

- Pipe cleaner or emery cloth

- Heat gun or blowtorch

- Replacement fittings or connectors

These tools are essential for repairing damaged plastic pipe threads. The adjustable wrench will help you loosen and tighten the fittings, while the pipe threader and cutter are necessary for creating new threads if needed. The hacksaw is useful for cutting the damaged section of the pipe, and the PVC solvent cement is used to bond the replacement fittings. The thread sealant and plumber’s tape are crucial for creating a watertight seal, and the pipe cleaner or emery cloth will ensure a clean and smooth surface for the repair. Lastly, the heat gun or blowtorch is used for heating and molding the plastic to fix the damaged threads, and replacement fittings or connectors may be required if the damage is severe.

Choosing The Right Sealants And Tapes:

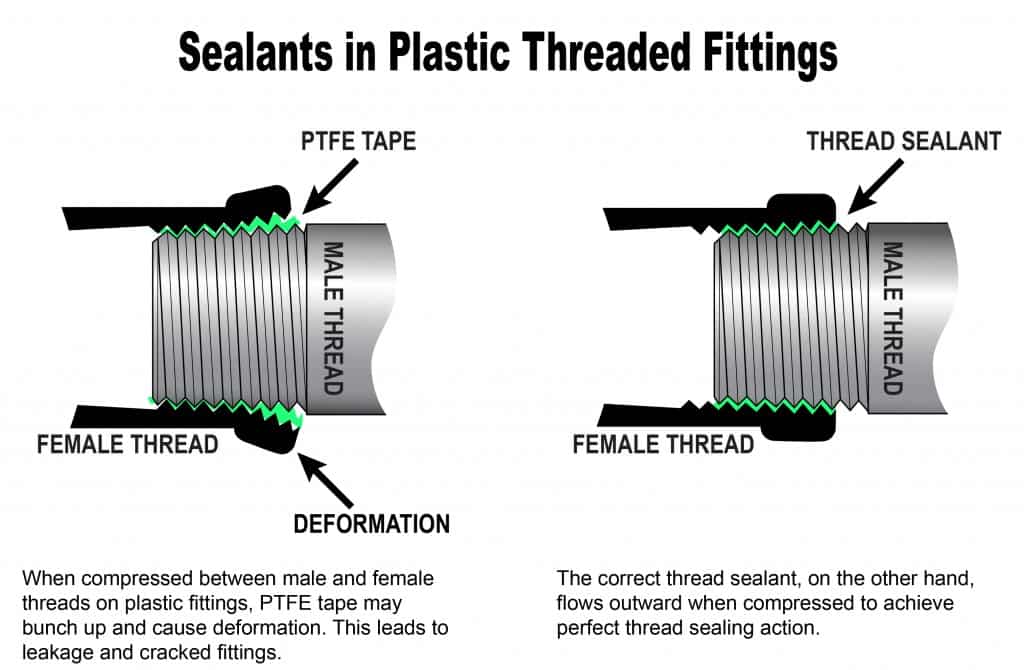

When it comes to repairing damaged plastic pipe threads, choosing the right sealants and tapes is essential for a durable and leak-free repair. The two primary options for sealing damaged threads are pipe thread sealant and plumber’s tape.

Pipe thread sealant is a viscous liquid that is applied to the male threads before screwing the joint together. It fills in any gaps and creates a tight seal as the connection is tightened. Pipe thread sealant is available in different formulations, including ones suitable for plastic pipes. Be sure to choose a sealant that is compatible with plastic to ensure a secure and long-lasting repair.

Plumber’s tape, also known as Teflon tape, is a thin, white tape that is wrapped around the male threads before assembly. It acts as a lubricant and creates a watertight seal when the joint is tightened. Plumber’s tape is easy to use and is suitable for both metal and plastic pipes. It is important to wrap the tape in the correct direction to prevent it from unraveling during installation.

By selecting the right sealant or tape for your specific repair job, you can ensure that the damaged plastic pipe threads are properly sealed and prevent any leaks or future damage.

Quick Fixes For Minor Thread Damage

To repair damaged plastic pipe threads, you can use a heat gun to soften the plastic, then re-form the threads with a thread sealant tape or pipe dope. Another method is to apply epoxy putty to create a new surface for the threads.

These quick fixes can help restore the functionality of the pipe threads without having to replace the entire fitting.

If you have minor thread damage on your plastic pipe, don’t worry! There are quick and easy fixes that you can do to repair it. In this section, we will explore two effective methods for repairing damaged plastic pipe threads: using thread seal tape and applying epoxy for reinforcement.

Using Thread Seal Tape Effectively

Thread seal tape, also known as plumber’s tape or PTFE tape, is a simple yet effective solution for minor thread damage. It is a thin, white tape that is wrapped around the male threads of the pipe fitting before screwing it into the female threads. Here’s how to use it effectively:

- Ensure that the threads are clean and free from debris.

- Start at the end of the male threads and wrap the tape in a clockwise direction, overlapping the previous layer by about half.

- Continue wrapping until you reach the end of the threads, ensuring that the tape is snugly applied.

- Once the tape is applied, carefully screw the fitting into the female threads, making sure not to cross-thread.

- Tighten the fitting until it is secure, but avoid over-tightening as it may cause damage.

Thread seal tape provides a tight and leak-free seal, preventing any water or gas from escaping through the damaged threads. It is a cost-effective and quick solution for minor thread damage.

Applying Epoxy For Reinforcement

If the thread damage is more severe, using epoxy can provide a stronger and more durable repair. Here’s how to apply epoxy for reinforcement:

- Clean the damaged threads thoroughly to remove any dirt, grease, or debris.

- Mix the epoxy according to the manufacturer’s instructions. Make sure to wear gloves and work in a well-ventilated area.

- Apply a thin layer of epoxy to the damaged threads using a small brush or applicator.

- Allow the epoxy to cure for the recommended time, ensuring that it is fully hardened.

- Once the epoxy is cured, you can then screw the fitting into the repaired threads.

Epoxy provides a strong bond that reinforces the damaged threads, making them more resistant to pressure and ensuring a secure connection. It is important to note that epoxy is a permanent solution, so make sure to apply it carefully and accurately.

Whether you choose to use thread seal tape or epoxy, these quick fixes for minor thread damage can save you time and money. By following these methods, you can repair damaged plastic pipe threads and restore the functionality of your plumbing system.

Reforming Threads With A Thread Chaser

To repair damaged plastic pipe threads, consider using a thread chaser to reform the threads. This tool helps to restore the integrity of the threads and ensure a secure connection for your plastic pipe fittings. By using a thread chaser, you can effectively address damaged threads and prevent leaks or inefficiencies in your plumbing system.

Introduction:

Plastic pipe threads are notorious for getting damaged over time, which can lead to leaks and other issues. Thankfully, there are several ways to repair damaged plastic pipe threads, including using a thread chaser. In this section, we will focus on how to reform threads with a thread chaser, providing you with a step-by-step guide.

Step-by-step guide to using a thread chaser:

1. Identify the damaged area: The first step is to identify the area of the plastic pipe threads that are damaged. This will help you determine if a thread chaser is the best solution for the problem.

2. Choose the right thread chaser: Once you have identified the damaged area, you need to choose the right thread chaser. Make sure the thread chaser matches the size and shape of the damaged threads.

3. Lubricate the thread chaser: Before using the thread chaser, apply lubricant to it. This will help it move smoothly over the threads and prevent any further damage.

4. Insert the thread chaser: Insert the thread chaser into the damaged area and turn it clockwise. Make sure to apply even pressure and avoid using too much force, as this can cause more damage.

5. Turn the thread chaser counterclockwise: Once you have turned the thread chaser clockwise, turn it counterclockwise to remove it from the damaged area. This will help remove any debris or plastic shavings.

6. Repeat the process: Repeat the process of inserting and turning the thread chaser until the threads are reformed. Make sure to check the threads periodically to ensure they are reforming properly.

When to opt for thread chasing:

Thread chasing is an excellent solution for repairing damaged plastic pipe threads. However, it is not always the best option. If the damage is severe or extensive, you may need to consider other solutions such as replacing the damaged section of the pipe. Additionally, if the threads are stripped, a thread chaser may not be effective. In such cases, you may need to use a different repair technique.

Conclusion:

Reforming threads with a thread chaser is a simple and effective way to repair damaged plastic pipe threads. By following the step-by-step guide outlined in this section, you can easily reform the threads and prevent leaks and other issues. However, it is essential to remember that thread chasing is not always the best solution and to consider other repair techniques if necessary.

The Role Of Thread Sealants

To repair damaged plastic pipe threads, you can use thread sealants such as pipe dope or thread sealing tape. Apply the sealant to the male threads and screw the joint together, allowing the taper to create a tight seal. If the threads are severely damaged, you may need to use products like JB Weld or tap the hole to accommodate a larger screw.

Remember to follow the NPT or BSP standards for proper thread repair.

The Role of Thread Sealants

If you need to repair damaged plastic pipe threads, one of the most critical steps is to apply the right thread sealant. Thread sealants play a crucial role in preventing leaks and ensuring a secure connection between pipes. In this article, we will discuss the different types of thread sealants and application techniques to achieve optimal results.

Types of Thread Sealants

There are two primary types of thread sealants: Teflon tape and pipe dope. Teflon tape, also known as plumber’s tape, is a thin, white tape that is wrapped around the male threads of the pipe before screwing it into the female threads. It creates a tight seal and prevents leaks. On the other hand, pipe dope is a thick, paste-like substance that is applied to the male threads of the pipe. It fills any gaps in the threads, creating a tight seal and preventing leaks.

Application Techniques for Optimal Results

To achieve optimal results when using thread sealants, follow these application techniques:

1. Clean the threads: Before applying the thread sealant, make sure the threads are clean and free of debris. Use a wire brush or cloth to clean the threads thoroughly.

2. Apply the sealant: Apply the thread sealant to the male threads of the pipe. Use a thin layer of pipe dope or wrap the Teflon tape around the threads in a clockwise direction.

3. Don’t overdo it: When applying pipe dope, use a small amount. Too much pipe dope can cause the threads to gum up and make it difficult to tighten the connection. Similarly, don’t wrap too much Teflon tape around the threads, as it can cause the threads to break or crack.

4. Tighten the connection: After applying the thread sealant, screw the pipe into the female threads. Use a wrench to tighten the connection, making sure not to overtighten.

In conclusion, thread sealants are an essential component when repairing damaged plastic pipe threads. The right sealant can prevent leaks and ensure a secure connection between pipes. By following the right application techniques, you can achieve optimal results and ensure a long-lasting repair.

Retapping For Severely Damaged Threads

Retapping is a useful technique for repairing severely damaged plastic pipe threads. This involves cutting new threads into the existing damaged ones, providing a secure and leak-free seal. With the right tools and techniques, retapping can be a cost-effective and efficient solution for repairing damaged plastic pipe threads.

Choosing The Correct Tap Size

To retap severely damaged plastic pipe threads, it is crucial to choose the correct tap size. This ensures that the new threads will fit properly and securely. When selecting the tap size, consider the diameter and pitch of the existing threads. You can measure these using a thread pitch gauge or consult the manufacturer’s specifications. It is essential to match the tap size precisely to avoid further damage or leaks in the repaired threads.

Procedure For Retapping Threads

Retapping severely damaged plastic pipe threads involves a step-by-step procedure to restore the threads’ functionality. Follow these instructions carefully for a successful repair:

- Start by cleaning the damaged threads using a wire brush or a pipe cleaning tool. This removes any debris or residue that may hinder the retapping process.

- Apply a lubricant, such as cutting oil, to the damaged threads. This helps to reduce friction and makes the retapping process smoother.

- Select the appropriate tap size, as mentioned earlier, and insert it into the damaged threads.

- Hold the tap firmly and slowly rotate it clockwise, applying gentle pressure. Make sure to keep the tap aligned with the original thread path.

- Continue rotating the tap until it reaches the desired depth or until you feel resistance. Be cautious not to overtighten or force the tap, as this can lead to further damage.

- Once the tap reaches the desired depth, carefully remove it from the threads.

- Inspect the retapped threads to ensure they are clean and free from any debris.

- Finally, test the repaired threads by screwing in a fitting or connector. Ensure that the threads engage smoothly and create a secure seal.

By following these steps, you can successfully retap severely damaged plastic pipe threads and restore their functionality. Remember to exercise caution and take your time during the retapping process to avoid any further damage or leaks.

Advanced Repair Techniques

Repairing damaged plastic pipe threads can be tricky, but with advanced repair techniques, it can be done effectively. One option is to heat and weld the fitting, while another is to use a thread sealer tape or pipe dope on the male threads before screwing the joint together.

It’s important to choose the right method for the specific type of damage to ensure a strong and lasting repair.

When it comes to repairing damaged plastic pipe threads, there are advanced techniques that can be employed for a more effective and long-lasting fix. These techniques include heat-based plastic welding and implementing PVC thread repair sleeves.

Heat-based Plastic Welding

Heat-based plastic welding is a technique used to repair damaged plastic pipe threads by fusing the damaged sections together. It involves using a heat source, such as a soldering iron or a heat gun, to melt the plastic and create a strong bond between the damaged parts. The melted plastic is then allowed to cool and solidify, resulting in a repaired thread that is as strong as the original.

To perform heat-based plastic welding, follow these steps:

- Clean the damaged area thoroughly to remove any dirt or debris.

- Apply heat to the damaged section using a soldering iron or a heat gun. Be careful not to overheat the plastic, as it can melt too much and cause further damage.

- Once the plastic is melted, carefully press the damaged sections together to create a strong bond.

- Hold the sections together until the plastic cools and solidifies.

- Inspect the repaired thread to ensure it is securely fused together.

Implementing Pvc Thread Repair Sleeves

Another advanced technique for repairing damaged plastic pipe threads is by implementing PVC thread repair sleeves. These sleeves are designed to fit over the damaged threads and provide a new, secure surface for the connection.

To implement PVC thread repair sleeves, follow these steps:

- Select a PVC thread repair sleeve that is the appropriate size for the damaged thread.

- Clean the damaged area and remove any loose or damaged threads.

- Apply a small amount of PVC cement to the inside of the repair sleeve.

- Slide the repair sleeve over the damaged thread, ensuring it fits snugly.

- Hold the repair sleeve in place for a few minutes to allow the PVC cement to bond.

- Inspect the repaired thread to ensure the repair sleeve is securely in place.

By utilizing these advanced repair techniques, you can effectively repair damaged plastic pipe threads and ensure a strong and secure connection. Whether you opt for heat-based plastic welding or PVC thread repair sleeves, these techniques offer reliable solutions for fixing damaged threads and extending the lifespan of your plastic pipes.

Prevention Tips For Future

Learn how to repair damaged plastic pipe threads with these prevention tips for the future. Follow easy steps like heating the fitting, welding the repaired fitting, and curing the repair to strengthen PVC threaded fittings and prevent cracking. Seal damaged pipe threads with thread sealing tape or pipe dope for a tighter connection.

Best Practices For Thread Maintenance

Proper maintenance of plastic pipe threads is crucial to prevent damage and ensure longevity. Implementing the following best practices can help maintain the integrity of the threads:

- Regular inspection for signs of wear and tear

- Using thread sealant or tape when assembling fittings

- Avoiding over-tightening during installation

- Keeping the threads clean and free from debris

Avoiding Common Mistakes

While maintaining plastic pipe threads, it’s important to steer clear of common mistakes that can lead to damage. Some key points to remember include:

- Avoid using excessive force when tightening fittings

- Avoid cross-threading during installation

- Avoid using incompatible sealants or tapes

- Do not overtighten or under-tighten the connections

Credit: www.fluoramics.com

Frequently Asked Questions

How Do You Seal Damaged Pipe Threads?

To seal damaged pipe threads, apply thread sealing tape or pipe dope to the male threads and screw the joint together. The taper creates a tight connection, achieving a seal. Use NPT or BSP standards for best results. Avoid starting with the forbidden phrases mentioned.

How To Repair Stripped Thread In Plastic?

To repair stripped thread in plastic, use a repair epoxy like JB Weld and coat the screw with Vaseline before inserting. Alternatively, tap the hole bigger for better grip. Avoid galling by running a die over damaged threads or using a nut to reform them.

Can Damaged Threads Be Repaired?

Yes, damaged threads can be repaired by running a die over the screw or bolt. It’s also possible to reform the threads by running a nut up and down, but this may risk the nut fusing to the thread.

How To Fix A Leaking Threaded Pvc Joint Without Cutting?

To fix a leaking threaded PVC joint without cutting, you have a few options. One option is to use a thread sealant, such as a compound, to fill gaps and prevent leaks. Another option is to use fiberglass resin tape or epoxy putty to temporarily repair the leak.

Silicone repair tape can also be used for small repairs.

How Can I Repair Damaged Plastic Pipe Threads?

You can use thread sealing tape or pipe dope to create a tight seal on the male threads and achieve a secure connection.

Conclusion

Repairing damaged plastic pipe threads is a simple task that can save you time and money. By following the right techniques and using the appropriate materials, such as thread sealant or epoxy putty, you can effectively restore the integrity of the pipe threads.

Whether you choose to use Teflon tape, apply a thread sealer, or even weld the fitting, there are multiple methods available to fix stripped or leaking threads. Remember to take the necessary precautions and follow the recommended steps to ensure a successful repair.

With these tips, you can confidently tackle any damaged plastic pipe threads and keep your plumbing system functioning smoothly.