Have you ever faced the frustration of dealing with a broken threaded PVC pipe? You know how annoying it can be.

But you’re not alone. Many people encounter this issue, and the good news is, you can fix it. Whether the pipe is part of your plumbing system or your garden irrigation setup, removing it might seem challenging. However, with the right guidance, you can tackle this problem efficiently.

Imagine the relief when you finally remove that stubborn piece and restore your system to full functionality. Dive into this article, and you’ll discover simple steps that can make this process easier than you ever thought possible. Don’t let a broken pipe disrupt your peace of mind. You have the power to fix it, and we’re here to show you how. Keep reading to become equipped with the knowledge that can save you time, effort, and money.

Tools And Materials Needed

Gather a pipe wrench, pliers, and hacksaw for removing broken threaded PVC pipes. Ensure you have safety gloves and goggles. Use a heat gun for stubborn pieces.

Removing a broken threaded PVC pipe can be a tricky task, but having the right tools and materials can make the process much smoother. It’s crucial to be prepared before starting the job to avoid unnecessary frustration. Imagine standing in your garage, ready to tackle the problem, only to discover you’re missing an essential tool. Been there, done that! So, let’s ensure you’re fully equipped to handle this task efficiently and safely.Basic Tools You’ll Need

You don’t need to own a toolbox worthy of a pro plumber to remove a broken PVC pipe. Start with a pipe wrench. It’s your primary tool for gripping and turning the pipe. If the pipe is too tight, a strap wrench can be a lifesaver, offering a firm grip without damaging the pipe surface. For those tricky situations where the pipe is shattered or stuck, a hacksaw or a reciprocating saw will help you cut through the material. A heat gun can also be handy if the pipe needs a little warming to loosen up.Specialized Tools For Tougher Jobs

Sometimes, basic tools aren’t enough. A PVC pipe extractor is designed specifically to remove broken threaded pieces from fittings. Think of it as a specialized screwdriver that can grip and twist out the remains of a pipe. A drill with a hole saw attachment can be used to carefully drill out larger pipe remnants. This method requires precision, so if you’re new to it, practice on a spare piece of PVC first.Essential Materials

Before starting, gather your materials. You’ll need replacement PVC pipe and fittings to ensure you can reassemble everything once the broken piece is removed. PVC primer and cement are essential for bonding new pipes securely. Always have a clean cloth or towel on hand. It helps keep the area dry, ensuring a better bond with the new pipe. A bucket can also be useful to catch any water still in the pipes.Safety Equipment

Safety should never be an afterthought. Equip yourself with a pair of safety goggles to protect your eyes from flying debris. Wear gloves to safeguard your hands from sharp edges and chemicals. Have you ever considered how much dust and debris can fly around when cutting PVC? A dust mask can prevent inhalation of particles, particularly if you’re using power tools.Organizing Your Work Space

Keeping your tools and materials organized can save a lot of time. Lay everything out on a workbench or a tarp. This reduces the chance of losing small parts or tools amidst the chaos. Have you ever found yourself searching for a tool you just had a moment ago? Keeping a neat workspace helps you focus on the task and reduces stress. Armed with these tools and materials, you’re ready to tackle that broken PVC pipe with confidence. What other preparations do you find essential before starting a home repair project? Let’s hear your thoughts!

Credit: www.reddit.com

Safety Precautions

Ensure proper eye protection to guard against flying debris. Use gloves to prevent hand injuries from sharp edges. Confirm the pipe is dry before using tools to avoid slipping accidents.

Removing a broken threaded PVC pipe can be a tricky task. But before you dive into the process, it’s crucial to prioritize safety. The right precautions can prevent accidents and ensure a smooth repair. Understanding these safety measures is not just a step; it’s a necessity that can save you from potential mishaps.Wear Protective Gear

Always start by wearing the appropriate protective gear. Safety goggles shield your eyes from debris and splinters. Gloves protect your hands from sharp edges and chemicals. These might seem like minor details, but they make a world of difference in ensuring your safety.Ensure Proper Ventilation

Working with PVC pipes may expose you to fumes, especially if you’re using chemical solvents. Make sure your workspace is well-ventilated. Open windows or use fans to keep fresh air circulating. This simple step can prevent dizziness or respiratory discomfort.Inspect Your Tools

Before using any tools, inspect them for damage. A faulty tool can lead to accidents. Check if the blade of your saw is sharp and securely fastened. Ensure your wrench is in good condition. Using reliable equipment not only makes the task easier but also safer.Secure The Workspace

Keep your workspace organized. Remove unnecessary clutter that can cause tripping or distractions. If working on a ladder, make sure it’s stable and on a level surface. A clear and secure environment prevents accidents and helps you focus on the task at hand.Turn Off Water Supply

Before you start the removal process, turn off the water supply. This prevents unexpected leaks and water damage. Imagine the frustration of working in a flood zone. Taking this precaution saves you from a potential mess and unnecessary stress.Handle Chemicals With Care

If you need to use solvents to loosen the PVC pipe, handle them carefully. Read the label instructions thoroughly. Use these chemicals sparingly and avoid direct contact with your skin. Proper handling protects you from chemical burns or irritation. Safety isn’t an afterthought; it’s the foundation of any successful project. Have you ever underestimated the importance of safety precautions? Implementing these measures not only protects you but also makes the task smoother and more efficient.Assessing The Damage

Removing a broken threaded PVC pipe starts with assessing the damage. This critical step ensures you approach the repair efficiently. Understanding the extent of the break can prevent further issues. It also helps you gather the necessary tools and materials. Below, explore the key aspects of assessing the damage.

Identifying The Break

Begin by identifying the break in the PVC pipe. Look for visible cracks or splits. Sometimes, the pipe may be broken inside a fitting. Use a flashlight to inspect hidden areas. A thorough check saves time and effort later.

Evaluating Accessibility

Next, evaluate the accessibility of the broken pipe. Determine if it’s in a tight space or open area. An accessible location makes repairs easier. Tight spaces may require special tools or techniques. Knowing this helps you plan effectively.

Removal Methods

Removing a broken threaded PVC pipe can be a challenging task, especially if you’re unfamiliar with the methods available. Whether the pipe is stuck due to corrosion, age, or over-tightening, knowing the right techniques can save you time and frustration. Let’s dive into some effective removal methods that can help you tackle this plumbing hurdle.

Using A Pipe Extractor

Pipe extractors are tools specifically designed to grip the inside of a broken pipe. You insert the extractor into the pipe, twist it, and pull the broken piece out. Imagine the relief when that stubborn pipe finally budges. It’s like solving a puzzle you thought was impossible. Do you have the right size extractor for your pipe? Remember, choosing the correct size is crucial for success.

Cutting And Extracting

If the pipe extractor doesn’t work, cutting might be your next best option. Carefully cut around the broken pipe section, ensuring you don’t damage surrounding areas. Ever felt like a surgeon in your own home? Precision is key here. Once cut, gently extract the broken pipe piece. How confident are you with handling a saw or cutter? Practice on a scrap piece first if needed.

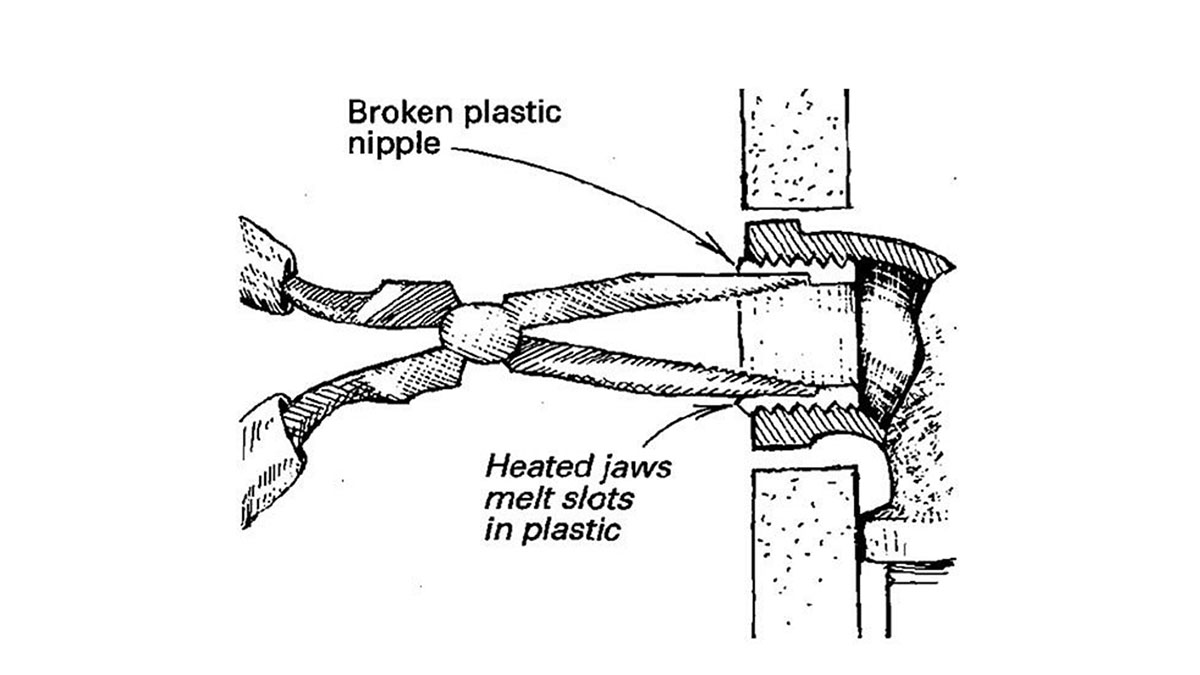

Heat Application Techniques

Applying heat can help loosen a stuck PVC pipe. Use a heat gun or hairdryer to warm the pipe gently, softening it enough to remove. Think about the difference a little heat can make—like warming a frozen lock on a cold winter day. But caution is essential; too much heat can damage the pipe. What’s your heat tolerance? Always start with the lowest setting to avoid mishaps.

Each method offers a different approach, and the right choice often depends on your tools and comfort level. Sometimes it’s trial and error, but with patience, you can conquer even the most stubborn pipes. Which method will you try first? Don’t hesitate to reach out for professional help if needed. After all, your home deserves the best care.

Preventing Further Damage

Safely removing a broken threaded PVC pipe prevents further damage. Use pliers or a pipe extractor tool carefully. This ensures the surrounding plumbing stays intact while you work.

When dealing with a broken threaded PVC pipe, the last thing you want is to make the situation worse. Preventing further damage is crucial to maintaining the integrity of your plumbing system. With a few careful steps, you can ensure the repair process goes smoothly without causing additional problems. Let’s dive into some practical tips to help you avoid common pitfalls.Avoiding Excessive Force

Applying too much force can cause more harm than good. It’s tempting to use brute strength to remove a broken piece, but this can lead to cracked fittings or damaged threads. Instead, take a moment to assess the situation. Is the piece stuck due to rust or debris? Try gently tapping around the pipe with a rubber mallet to loosen it. This can often help without the risk of breaking other components. Have you ever tried to fix something and ended up with a bigger mess? It’s a common scenario, especially if you’re in a hurry. Patience and a gentle hand can save you from costly repairs later.Proper Tool Usage

Using the right tools is essential. A strap wrench can be your best friend in these situations. Unlike metal tools, it provides grip without scratching or damaging the pipe. Does the tool you’re using fit the task? Using pliers or a wrench that’s too small can slip and cause injury or additional damage. Ensure your tools are in good condition and appropriate for the size of the pipe you’re working on. Have you ever used a tool incorrectly because it seemed convenient? It happens more often than you’d think. Investing in the right tools not only helps in the current task but can also be useful for future repairs. Preventing further damage is about being cautious and prepared. By avoiding excessive force and ensuring proper tool usage, you can tackle the job confidently. What other methods have you found helpful in handling delicate repairs?

Credit: diy.stackexchange.com

Repair And Replacement

Removing a broken threaded PVC pipe is only half the battle. The next step involves repair and replacement to ensure the plumbing system functions properly. This process may seem daunting. But with the right guidance, it can be straightforward.

Choosing Replacement Pipes

Ensure the new pipe matches the old one in size and type. This is crucial for compatibility. Opt for quality PVC pipes designed for your specific needs. Check local hardware stores for the best options. Always select a pipe that can withstand the pressure and temperature of its environment.

Sealing And Securing Joints

Sealing joints is critical to prevent leaks. Use a reliable PVC primer and cement to secure joints firmly. Apply the primer first, then follow with the cement. Ensure all surfaces are clean before application. Hold the joint in place for a few seconds to let it set. This ensures a tight and secure fit.

Maintenance Tips

Keeping your PVC pipes in good condition helps avoid problems. Regular care ensures the pipes last longer. Follow some simple maintenance tips. It can prevent damage and costly repairs.

Regular Inspection

Check your PVC pipes often. Look for cracks or leaks. Early detection of issues prevents bigger problems. Use a flashlight to inspect dark areas. Pay attention to joints and connections. These areas are prone to wear.

Handling Pvc Pipes

Handle PVC pipes with care. Avoid dropping or hitting them. This can cause cracks or breaks. When installing, use the correct tools. A pipe wrench is ideal. Do not overtighten fittings. It can damage the threads.

Credit: www.finehomebuilding.com

Frequently Asked Questions

What Tools Do I Need To Remove Broken Pvc Pipe?

You need a pipe extractor, pliers, and a heat gun. Safety gloves too.

Can I Remove Broken Pvc Pipe Without A Professional?

Yes. Follow safety steps and use the right tools. It’s doable.

How Do I Safely Remove A Broken Pvc Pipe?

Turn off water. Use a heat gun to soften. Extract gently.

What Causes A Threaded Pvc Pipe To Break?

Over-tightening or freezing can break it. Regular checks help avoid issues.

Is It Possible To Prevent Pvc Pipe Breakage?

Yes. Avoid over-tightening. Protect from cold. Regular inspections are key.

Conclusion

Removing a broken threaded PVC pipe can be tricky. But with patience and the right tools, it’s manageable. Start by assessing the damage carefully. Use pliers or a pipe extractor for removal. Take care not to damage surrounding areas. Clean the pipe threads thoroughly after removal.

This ensures a snug fit for the new pipe. Always wear safety gear to protect yourself. By following these simple steps, you can avoid costly repairs. Keep your plumbing in top shape. It saves time and stress in the long run.