A ground rod should be placed at a minimum distance of two feet from any building structure to prevent potential disruptions. It is also recommended to install the ground rod near the home’s electrical panel.

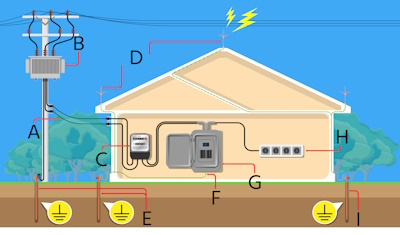

When it comes to electrical systems, safety is of utmost importance. One crucial aspect of electrical safety is the proper installation of ground rods. Ground rods play a vital role in grounding electrical systems, providing a path for electricity to safely dissipate into the ground.

However, it is essential to know the appropriate distance between a ground rod and the electrical panel to ensure optimal performance and safety. In this blog, we will explore how far a ground rod can be from the panel, taking into account the guidelines and regulations set by industry experts. By understanding these requirements, you can ensure the effective grounding of your electrical system and mitigate potential hazards.

Ground Rods And Electrical Safety

A ground rod should be placed at a minimum distance of two feet from any building structure to prevent potential disruptions. It’s also recommended to install the ground rod near the home’s electrical panel for enhanced safety and effectiveness. This positioning ensures optimal electrical safety and grounding performance.

The Role Of Ground Rods In Electrical Systems

Ground rods play a crucial role in electrical systems by providing a safe path for electrical currents to be directed into the ground in the event of a fault or surge. This helps prevent electrical shock, fire hazards, and equipment damage, ensuring the safety of both the electrical system and the individuals interacting with it.

Key Safety Considerations For Ground Rod Installation

When installing ground rods, several key safety considerations must be taken into account to ensure effective grounding and electrical safety. Proper installation practices, including the placement of ground rods and the quality of connections, are essential to maintain the integrity of the electrical system and protect against potential hazards.

Credit: www.jwkhomeinspections.com

National Electrical Code Guidelines

National Electrical Code (NEC) guidelines provide specific requirements for the placement and spacing of ground rods in electrical systems. Adhering to these guidelines is crucial to ensure the safety and functionality of the electrical infrastructure in buildings.

Nec Requirements For Ground Rod Placement

According to the NEC, ground rods must be placed in a location that ensures effective grounding of the electrical system. It is recommended to position the ground rod at a minimum distance of 2 feet from any building structure to prevent potential disruptions to the grounding system.

Understanding Ground Rod Spacing

The NEC also provides guidelines for the spacing of ground rods. While there are no exact rules for the placement of ground rods, it is advisable to install them at a distance that allows for effective grounding and minimizes the risk of electrical hazards. Ground rods should be placed at a distance that ensures proper grounding, taking into consideration factors such as soil conductivity and the electrical system’s requirements.

Optimal Distance From Panel To Ground Rod

To ensure optimal grounding, the ground rod should be placed a minimum distance of two feet from any building structure. It’s also recommended to install the ground rod near the electrical panel to prevent potential disruptions. Following these guidelines helps maintain effective electrical grounding for safety and functionality.

The optimal distance from the electrical panel to the ground rod is an important consideration for ensuring effective grounding in a building. It plays a crucial role in maintaining electrical safety and preventing potential disruptions. By understanding the minimum safe distance and the factors affecting ground rod placement, you can ensure that your electrical system operates efficiently.

Minimum Safe Distance

According to electrical standards and regulations, it is advisable to position the ground rod at a minimum distance of two feet from any building structure. This distance helps to prevent any potential interference or disruptions that could occur if the ground rod is placed too close to the building. By maintaining this minimum safe distance, you can ensure that the ground rod functions effectively in grounding electrical currents.

Factors Affecting Ground Rod Placement

Several factors can influence the placement of the ground rod in relation to the electrical panel:

- Proximity to the electrical panel: Installing the ground rod near the electrical panel is recommended for efficient grounding. This ensures a shorter path for the electrical current to travel, reducing the risk of electrical hazards.

- Soil conditions: The type of soil in the area can affect the performance of the ground rod. Soil with high resistance may require additional ground rods or longer distances between the panel and the ground rod to achieve optimal grounding.

- Electrical system size: The size and capacity of the electrical system can also impact the placement of the ground rod. Larger systems may require multiple ground rods or specific distances to ensure effective grounding.

- Local regulations: It is important to be aware of any specific regulations or codes in your local area that may dictate the placement of ground rods. These regulations are in place to ensure electrical safety and compliance with standards.

Considering these factors when determining the optimal distance from the panel to the ground rod will help ensure a properly grounded electrical system, minimizing the risk of electrical hazards and disruptions.

Ground Rod Installation Techniques

To ensure effective grounding, it is recommended to position a ground rod at a minimum distance of two feet from any building structure. Installing the ground rod near the home’s electrical panel is also advisable for optimal performance and safety.

When it comes to grounding systems, the installation of ground rods is a crucial step to ensure the safety and effectiveness of the system. Ground rods provide a path for electrical current to safely dissipate into the earth, protecting both people and equipment from potential electrical hazards. In this section, we will explore the step-by-step installation process of ground rods and discuss troubleshooting common issues that may arise.

Step-by-step Installation Process

Proper installation of ground rods is essential for a reliable grounding system. Following these step-by-step guidelines will help ensure a successful installation:

- Choose the right location: Select a suitable location for the ground rod, preferably within two feet of any building structure. This positioning helps prevent potential disruptions and allows for convenient connection to the electrical panel.

- Prepare the ground: Clear the area around the chosen location of any obstructions, such as rocks or roots, to facilitate easy installation.

- Drive the ground rod: Using a ground rod driver or a sledgehammer, drive the ground rod vertically into the earth until only a few inches remain above the ground level. Ensure that the rod is securely and firmly in place.

- Connect the grounding conductor: Attach the grounding conductor, typically made of copper or aluminum, to the ground rod using a clamp or connector specifically designed for this purpose. Ensure a tight and secure connection to optimize the conductivity of the grounding system.

- Route the grounding conductor: Run the grounding conductor from the ground rod to the electrical panel, following the necessary routing guidelines and maintaining proper separation from other electrical conductors.

- Connect to the electrical panel: Terminate the grounding conductor at the designated grounding terminal or bus bar in the electrical panel. Ensure a solid and secure connection to establish an effective grounding pathway.

- Test the grounding system: Once the installation is complete, it is essential to conduct thorough testing to verify the effectiveness of the grounding system. Use appropriate testing equipment to measure the resistance and continuity of the ground connection.

Troubleshooting Common Issues

Despite following the installation process diligently, it is possible to encounter certain issues that may affect the performance of the grounding system. Here are some common problems that may arise and possible troubleshooting solutions:

- High ground resistance: If the measured resistance of the grounding system is higher than expected, it may indicate poor soil conductivity or inadequate ground rod installation. Consider using additional ground rods or consult a professional to improve the system’s performance.

- Loose connections: Loose or poorly connected grounding conductors can compromise the effectiveness of the grounding system. Regularly inspect and tighten all connections to ensure a secure and reliable pathway for electrical current.

- Corrosion: Over time, corrosion can deteriorate the conductivity of grounding connections. Routinely inspect the grounding system for signs of corrosion and replace any corroded components to maintain optimal performance.

- Improper grounding conductor routing: Incorrect routing of the grounding conductor can lead to interference with other electrical conductors or create safety hazards. Ensure proper separation and routing of the grounding conductor to prevent any potential issues.

By following the step-by-step installation process and addressing common troubleshooting issues, you can ensure a robust and reliable grounding system for your electrical setup. Remember to consult local electrical codes and regulations for specific guidelines regarding ground rod installation distances and requirements.

Ground Wire Specifications

When it comes to electrical safety, grounding is a crucial component. A ground wire is used to provide an electrical path to the earth, ensuring that any electrical current that escapes from its intended circuit will be safely absorbed by the earth. In this article, we will focus on the ground wire specifications, specifically the maximum length considerations and choosing the right ground wire size.

Choosing The Right Ground Wire Size

Choosing the right ground wire size is important to ensure that it can handle the electrical load it is intended to carry. The size of the ground wire should be based on the size of the circuit, and the distance between the ground rod and the electrical panel.

The National Electrical Code (NEC) provides guidelines on the minimum size of the ground wire based on the amperage of the circuit. For example, a 15-amp circuit requires a minimum of 14-gauge ground wire, while a 20-amp circuit requires a minimum of 12-gauge ground wire.

However, it is important to note that these are minimum requirements, and it is always better to use a larger gauge wire to ensure safety and stability in the electrical system.

Maximum Length Considerations

One of the most common questions related to ground wire specifications is the maximum length that a ground wire can be run. If you are referring to the grounding electrode conductor, there are no maximum length restrictions. However, it is important to note that the longer the run, the larger the gauge wire needed to ensure proper grounding.

It is also important to consider the distance between the ground rod and the electrical panel. The NEC recommends a minimum distance of two feet between the ground rod and any building structure to prevent potential disruptions. Installing the ground rod near the home’s electrical panel is also recommended.

Special Cases In Grounding

When it comes to grounding, there are special cases to consider, such as the distance between the ground rod and panel. The NEC code does not specify a maximum distance, but it is recommended to place the ground rod at least 2 feet away from any building structure and near the electrical panel.

Dealing With Multiple Sub Panels

When it comes to grounding multiple sub panels, it’s important to remember that each panel should have its own grounding electrode system. This means that each sub panel should be connected to its own ground rod, which should be located as close as possible to the panel. However, if you have multiple sub panels located in close proximity to each other, it is acceptable to use a common ground rod for all of them.

Challenges With Driving Ground Rods

Driving a ground rod can be challenging in certain situations, such as when the soil is hard or rocky. If you are unable to drive a ground rod to the required depth of 8 feet, you may be able to use multiple ground rods spaced 6 feet apart. The ground rods should be connected with a grounding electrode conductor that is sized appropriately for the distance between the rods and the size of the electrical service.

If you are still unable to drive a ground rod far enough, you may need to consider alternative grounding methods, such as a ground plate or a ground ring. These methods can be effective in situations where driving a ground rod is not feasible.

Ensuring Proper Grounding

Regardless of the grounding method you choose, it’s important to ensure that the grounding system is properly installed and connected. This includes verifying that the grounding electrode conductor is the correct size and length, and that it is connected to both the ground rod and the electrical service panel with approved connectors.

Additionally, it’s important to periodically inspect the grounding system to ensure that it is still in good condition. This includes checking the ground rod for signs of corrosion or damage, and verifying that the grounding electrode conductor is still securely connected to both the ground rod and the panel.

In conclusion, when dealing with special cases in grounding, it’s important to follow the guidelines set forth by the National Electrical Code and to ensure that the grounding system is properly installed and maintained. By doing so, you can help ensure the safety and reliability of your electrical system.

Faqs In Ground Rod Installation

When it comes to ground rod installation, one frequently asked question is, “How far can a ground rod be from the panel? ” According to NEC guidelines, there are no specific distance requirements, but it is recommended to position the ground rod at least two feet away from any building structure to prevent disruptions.

Additionally, installing the ground rod near the electrical panel is advisable.

Addressing Common Concerns

Ground rod installation is an essential part of ensuring electrical safety and preventing electrical hazards. However, there are often common concerns and questions that arise when it comes to the distance between the ground rod and the panel. In this section, we will address some of these concerns and provide expert answers to frequently asked questions.

Expert Answers To Frequent Questions

1. How Far Can A Ground Rod Be From The Panel?

According to the National Electrical Code (NEC), there are no specific distance requirements for the placement of a ground rod in relation to the panel. However, it is advisable to position the ground rod at a minimum distance of two feet from any building structure to prevent potential disruptions. Additionally, installing the ground rod near the home’s electrical panel is recommended for effective grounding.

2. What Is The Maximum Length That A Ground Wire Can Be Run?

When referring to the grounding electrode conductor, there are no maximum length restrictions specified by the NEC. However, it is important to ensure that the conductor is appropriately sized to handle the electrical load and meets the code requirements for conductivity.

3. What If I Can’t Drive A Ground Rod Far Enough?

If you are unable to drive a ground rod to the desired depth, it is recommended to consult with a licensed electrician or electrical engineer. They can evaluate alternative grounding methods or suggest solutions to ensure proper grounding and electrical safety.

4. Where Should A Grounding Rod Be Placed?

The grounding rod should be placed in an area with good soil conductivity. It is important to avoid areas with rocky or sandy soil, as they may not provide sufficient grounding. Additionally, the ground rod should be positioned away from any underground utilities to prevent damage.

5. What Size Of Wire Do You Run To A Ground Rod?

The size of the wire used to connect the ground rod to the panel depends on the electrical load and the code requirements. It is crucial to consult the NEC and follow the appropriate guidelines to ensure the correct wire size is used for grounding purposes.

6. Are There Any Requirements For Distance To The Ground Rod?

The NEC does not specify any specific distance requirements for the ground rod. However, it is essential to position the ground rod at a sufficient distance from any building structure and ensure proper grounding connections to maintain electrical safety.

When it comes to ground rod installation, it is crucial to follow the NEC guidelines and consult with a licensed professional to ensure compliance with local electrical codes and regulations. By addressing these common concerns and providing expert answers to frequently asked questions, you can have a better understanding of the ground rod installation process and its importance in maintaining electrical safety.

Credit: tameson.com

Maintaining Compliance And Safety

When it comes to electrical systems, ensuring compliance with safety standards is of utmost importance. One crucial aspect of electrical safety is the proper installation and maintenance of ground rods. Ground rods are an essential component of grounding systems as they provide a path for electrical current to safely dissipate into the ground, protecting both people and equipment from potential hazards.

Regular Inspection And Testing

Regular inspection and testing of ground rods are vital to maintain compliance and safety. It is recommended to perform visual inspections of the ground rod and its connections at least once a year. Look for signs of corrosion, damage, or loose connections. Additionally, periodic testing using a ground resistance tester can help identify any potential issues with the grounding system.

Updates To Grounding Standards

Grounding standards and regulations are regularly updated to ensure the highest level of safety. It is important to stay informed about these updates and make any necessary adjustments to your grounding system. Keeping up with the latest standards will help you maintain compliance and ensure the safety of your electrical system.

When it comes to the distance between the ground rod and the panel, there are no specific rules set by the National Electrical Code (NEC). However, it is generally recommended to position the ground rod at a minimum distance of two feet from any building structure. This helps prevent potential disruptions and allows for proper grounding.

Installing the ground rod near the home’s electrical panel is also a common practice. This ensures that the grounding system is in close proximity to the main source of electrical power, optimizing its effectiveness in diverting electrical current safely into the ground.

Remember, maintaining compliance with grounding standards and regularly inspecting and testing your ground rods are crucial for the safety of your electrical system. By following these practices, you can ensure the proper functioning of your grounding system and minimize the risk of electrical hazards.

Credit: www.electrical-contractor.net

Frequently Asked Questions

How Far Apart Should Ground Rods Be For 200 Amp Service?

For a 200 amp service, ground rods should be placed a minimum distance of two feet from any building structure to prevent potential disruptions. It is also recommended to install the ground rod near the home’s electrical panel.

What Is The Nec Code For Ground Rods?

The NEC code for ground rods states that driven grounding electrodes should be installed at least 6 feet apart, and should be positioned at a minimum distance of 2 feet from any building structure. There are no maximum length restrictions for the grounding electrode conductor.

It is recommended to install the ground rod near the home’s electrical panel.

How Close Can A Panel Be To The Ground?

A panel should be at least 2 feet from the ground for safety and to prevent disruptions.

What Is The Maximum Length That A Ground Wire Can Be Run?

There is no maximum length restriction for a ground wire. It can be run as needed.

How Far Should A Ground Rod Be Installed From The Panel?

The ground rod should be installed at a minimum distance of two feet from any building structure to prevent potential disruptions. It’s also recommended to position it near the home’s electrical panel.

Conclusion

To sum it up, the distance between a ground rod and a panel is an important factor to consider when installing electrical systems. While there are no exact rules for placing a ground rod, it is recommended to position it at a minimum distance of two feet from any building structure to prevent potential disruptions.

Additionally, it is advisable to install the ground rod near the home’s electrical panel. By following these guidelines, you can ensure the proper functionality and safety of your electrical system.