Are you planning a home renovation or a DIY project? If so, you’ve probably heard of cement boards.

They’re a popular choice for their durability and versatility, especially in areas prone to moisture. But when it comes to choosing the right thickness, you might find yourself stuck between half-inch and quarter-inch options. How do you decide which one is right for your needs?

This decision can impact the longevity and effectiveness of your work. We’ll break down the key differences between half and quarter cement boards, helping you make an informed choice. You’ll discover which option offers better support for your tiles, where each thickness excels, and how your choice can affect installation costs and time. Stay with us to ensure your project stands the test of time and meets your expectations. Your perfect renovation is just a few insights away!

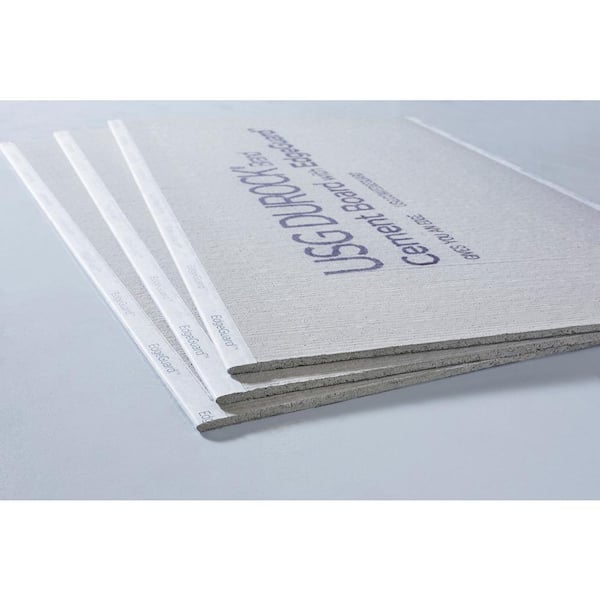

Cement Board Basics

Cement boards are essential in construction for their durability and versatility. They play a crucial role in both interior and exterior applications. Understanding the differences between half and quarter cement boards can help in choosing the right option for your project.

Understanding Cement Boards

Cement boards are made from cement and reinforcing fibers. They offer a sturdy base for tile installations. Their resistance to moisture makes them ideal for wet areas like bathrooms and kitchens. These boards come in various thicknesses, including half-inch and quarter-inch options.

The thickness of a cement board affects its strength and application. Half-inch boards are thicker and provide greater stability. Quarter-inch boards are lighter, suitable for areas with less load-bearing requirements.

Common Applications

Cement boards are used for flooring underlayment. They serve as a reliable base for tile and stone floors. In shower installations, cement boards prevent water damage.

Half-inch boards are commonly used for walls and floors. Their thickness ensures durability in high-traffic areas. Quarter-inch boards are often used for countertops. They provide a smooth surface for tile adhesion.

Both types of cement boards are crucial for home renovations. Choosing the right thickness depends on the specific needs of the project.

Half-inch Cement Board

When tackling a home improvement project, choosing the right materials can be a game-changer. One such material that’s often debated is the half-inch cement board. This versatile building component is a staple in many renovation projects, offering durability and reliability. Have you ever wondered why professionals opt for the half-inch variety? Let’s dive into its features, benefits, and ideal use cases.

Features And Benefits

The half-inch cement board is known for its robustness and strength. It’s engineered to withstand moisture, making it an excellent choice for areas prone to dampness like bathrooms and kitchens.

It provides a stable base for tiles, ensuring longevity and reducing the risk of cracking. When you’re installing tiles, you want them to last, right?

Moreover, this thickness offers soundproofing benefits. If you live in a bustling neighborhood or have noisy kids, this feature is a blessing in disguise.

Installation is a breeze with the right tools. You’ll find that cutting and fitting the boards is straightforward, even if you’re not a seasoned pro.

Furthermore, it’s fire-resistant. This adds an extra layer of safety to your home—a reassuring thought for any homeowner.

Ideal Use Cases

Where should you use half-inch cement board? Bathrooms are an obvious choice. Its moisture-resistant properties make it a perfect fit for shower walls and floors.

Consider using it in the kitchen behind your stove or under your countertops. You’ll appreciate the peace of mind knowing your surfaces are protected.

If you’re working on a basement renovation, this board’s durability is unmatched. It handles the temperature and humidity fluctuations with ease.

For outdoor projects, such as patio or deck renovations, its weather-resistant nature is ideal. You can confidently host BBQs without worrying about board damage.

Think about your home’s future. Wouldn’t you want a material that offers longevity and reliability? The half-inch cement board is a choice you won’t regret.

Quarter-inch Cement Board

Quarter-Inch Cement Board has become a favorite among DIY enthusiasts and professional builders alike. Its thin profile offers unique advantages that can streamline your projects without compromising on quality. Whether you’re updating your bathroom or installing new countertops, understanding the features and benefits of Quarter-Inch Cement Board can help you make more informed decisions.

Features And Benefits

The Quarter-Inch Cement Board is known for its lightweight nature, making it easier to handle and cut. You don’t have to worry about heavy lifting or complex installations.

Its slim design is perfect for projects where space is a premium but strength cannot be compromised. You can achieve a smooth finish without adding unnecessary bulk.

This board is resistant to moisture, ensuring longevity in areas like bathrooms and kitchens. You can trust it to withstand water exposure without deteriorating.

Additionally, its compatibility with a variety of finishing materials offers versatility. Whether you’re planning to install tiles or paint over it, the Quarter-Inch Cement Board provides a solid foundation.

Ideal Use Cases

Quarter-Inch Cement Board is excellent for residential projects that require a sleek finish without sacrificing durability. Think about your kitchen backsplash or bathroom walls.

It’s also a great choice for countertop underlayment. You can ensure a firm base for your countertops without adding excessive height.

Consider using it for flooring underlayment as well. It provides the necessary support while keeping the floor height low, ideal for areas with tight transitions.

Have you ever faced the challenge of fitting new tiles in a small bathroom space? The Quarter-Inch Cement Board can be your solution, offering a sturdy base without taking up much room.

What other creative applications can you think of for this versatile material? Explore possibilities and let it inspire your next project.

Credit: www.oldhouseguy.com

Comparative Analysis

Understanding the differences between half and quarter cement boards is crucial. Both are essential for construction projects but serve different purposes. This analysis helps in making informed decisions.

Thickness Impact On Durability

Thickness plays a vital role in a cement board’s durability. A half-inch cement board offers more strength. It withstands heavy tiles and intense foot traffic better. Quarter-inch boards are lighter and easier to cut. They are suitable for walls and less demanding areas. This makes them ideal for lighter installations.

Cost Considerations

Budget is a significant factor in construction. Half-inch cement boards are generally more expensive. They offer greater durability and support. This justifies the higher cost for many. Quarter-inch boards are more affordable. They are perfect for projects with budget constraints. Choose based on project needs and budget allowances.

Installation Considerations

Choosing between half-inch and quarter-inch cement board impacts installation ease and durability. Thicker boards offer better support for heavy tiles. Thinner options are lighter, ideal for walls. Always ensure compatibility with your project needs.

When installing cement boards, choosing between half-inch and quarter-inch thicknesses can significantly impact your project. The decision often boils down to specific installation considerations that affect ease, tool requirements, and overall efficiency. Let’s dive into what you need to know to make an informed choice.Ease Of Installation

Choosing the right thickness can make your work smoother. Half-inch cement boards are sturdier, offering more support for wall tiles. They are often the go-to for high-moisture areas like bathrooms. On the flip side, quarter-inch boards are lighter and easier to handle. They’re perfect for flooring projects where weight is a concern. I remember a project where the lightweight quarter-inch boards saved my back and time. Which thickness aligns with your project needs? Consider the ease of handling as much as the final look.Tool Requirements

Tools can either make or break your installation process. For half-inch boards, you’ll need a drill with cement board screws. These boards demand more cutting power, so a carbide-tipped blade is essential. Quarter-inch boards, being thinner, are easier on your tools. A regular utility knife can suffice for scoring and snapping. You might find yourself using fewer tools, which is a bonus if you’re new to DIY projects. Have you checked your toolbox lately? Ensure you have the right tools for the job to avoid unnecessary trips to the hardware store. In essence, the choice between half and quarter-inch cement boards hinges on your specific project requirements. Prioritizing ease of installation and having the right tools at your disposal will pave the way for a successful endeavor. So, which board will you choose for your next project?

Credit: www.homedepot.com

Environmental Factors

Cement boards face various environmental challenges. Knowing their resistance helps in making the right choice. Environmental factors like moisture and temperature affect cement board performance.

Moisture Resistance

Cement boards resist moisture effectively. Half-inch boards offer more protection. They withstand wet environments better. Quarter-inch boards suit drier areas. They are less robust against water exposure.

In bathrooms, kitchens, and basements, moisture resistance is critical. Choose the right thickness for these spaces. This ensures long-lasting durability.

Temperature Tolerance

Temperature changes impact cement board strength. Half-inch boards handle heat fluctuations well. They provide stability in extreme climates. Quarter-inch boards adapt to moderate conditions.

For outdoor installations, consider temperature tolerance. Half-inch boards are ideal for weather-prone areas. They reduce the risk of cracking or warping.

Making The Right Choice

Choosing between half-inch and quarter-inch cement boards can be challenging. Each option has unique benefits. Understanding these differences is key. It ensures the success of your project. This section will guide you in making an informed choice.

Project Type And Requirements

The project type greatly influences the cement board choice. For flooring, a thicker board offers better support. Half-inch boards are ideal for heavy-duty applications. For wall installations, quarter-inch boards work well. They are lighter and easier to handle. Consider the project environment too. Wet areas like bathrooms need moisture resistance. Half-inch boards often provide better water resistance.

Expert Recommendations

Experts recommend assessing your project’s specific needs. Half-inch boards are suitable for high-traffic areas. They provide durability and strength. Quarter-inch boards are perfect for lighter projects. They are easier to cut and install. Consult a professional if unsure. They can provide valuable insights and advice.

Credit: www.homedepot.com

Frequently Asked Questions

What Is The Difference Between Half And Quarter Cement Board?

Half cement board is thicker and stronger. Quarter cement board is thinner and lighter. Both serve different purposes.

Is Half Cement Board Better For Flooring?

Yes, half cement board provides more support. It is better for flooring projects due to its strength.

Can I Use Quarter Cement Board For Walls?

Yes, quarter cement board is suitable for walls. It’s lighter and easier to install.

Which Is More Cost-effective, Half Or Quarter Cement Board?

Quarter cement board is usually cheaper. It can be more cost-effective for projects needing less strength.

How Do I Choose Between Half And Quarter Cement Board?

Consider the project needs. Use half for strength and quarter for lighter, easier installations.

Conclusion

Choosing between half and quarter cement board affects your project. Half cement board offers more strength. It’s ideal for areas with heavy moisture. Quarter cement board is lighter. Easier to cut and install. Best for projects with lower moisture exposure.

Understand your needs before deciding. Consider durability and installation ease. Both types have benefits. Match them with your specific requirements. Your choice determines the outcome and longevity. Think about cost and effort involved. Make an informed decision for lasting results.

Select wisely for a successful project.