Is your ball valve leaking internally? You’re not alone.

This common issue can lead to bigger problems if not addressed promptly. Imagine turning the faucet, expecting a smooth flow, but instead, you’re greeted with unexpected drips or reduced pressure. Frustrating, right? But don’t worry. You’re about to discover why this happens and, more importantly, how you can fix it.

Understanding the root of the problem can save you time, money, and a headache. You’ll learn how to spot signs of internal leaks and what steps you can take to ensure your ball valve works flawlessly. So, if you’re tired of dealing with leaks and want to regain control of your plumbing, keep reading. You won’t want to miss these insights.

Causes Of Internal Leakage

Internal leaks in ball valves often result from worn seals or damage to the valve seat. Accumulated debris or improper installation can also contribute to leakage. Regular maintenance helps prevent these issues.

Understanding the causes of internal leakage in ball valves is crucial for maintaining a reliable piping system. Internal leaks can disrupt operations and lead to costly repairs if not addressed promptly. Identifying the root causes can help you prevent future issues and ensure the longevity of your equipment. Let’s explore some common reasons why ball valves might leak internally.Wear And Tear

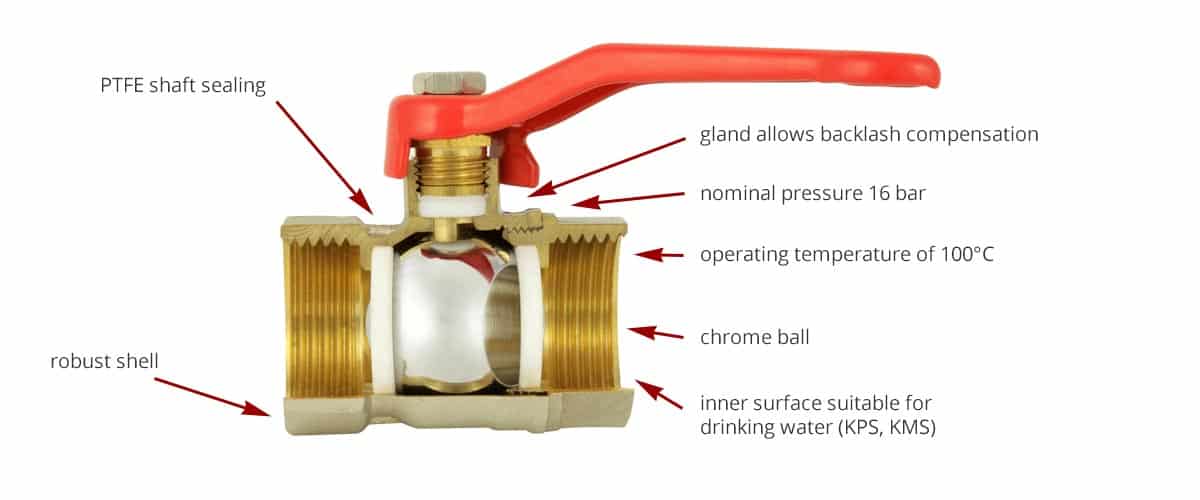

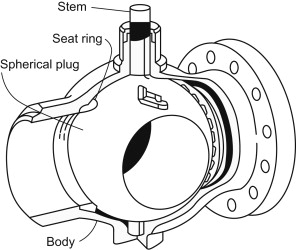

Ball valves are subjected to constant movement and pressure. Over time, this can lead to wear and tear on the valve’s internal components. The seats and seals, in particular, are prone to degradation. Regular inspection and maintenance are key to spotting early signs of wear. Consider scheduling routine checks to replace worn-out parts before they cause significant leakage.Corrosion Issues

Corrosion is a silent but relentless enemy of metal components. Exposure to harsh chemicals or extreme environmental conditions can corrode the valve’s body or internal parts. Opt for corrosion-resistant materials when selecting a ball valve. Stainless steel or brass valves are great options for corrosive environments. Are your valves showing signs of rust or discoloration? It might be time to consider an upgrade.Improper Installation

A poorly installed ball valve can lead to misalignment and internal leakage. Ensure that your valve is installed following the manufacturer’s guidelines. Misalignment during installation can damage seals, leading to leaks. Always double-check the alignment and secure fittings to prevent future issues. Have you checked if your installation matches the recommended procedures? Addressing these causes promptly can save you time and money. Keep an eye on your systems and act fast when you notice something off. After all, prevention is always better than cure when it comes to ball valve maintenance.Identifying Leakage Signs

Spotting internal leaks in ball valves involves checking for unusual noises or pressure drops. Look for visible signs like moisture or rust around the valve. Regular inspections help prevent damage and ensure efficient operation.

When a ball valve starts leaking internally, it can lead to unexpected problems that disrupt your system’s efficiency. Identifying leakage signs early can save you from costly repairs and downtime. This process begins with a few straightforward checks that you can easily conduct yourself.Visual Inspection

Begin with a thorough visual inspection. Look for water stains or moisture around the valve and pipes, which might indicate a leak. A flashlight can help illuminate hard-to-see areas, making it easier to spot telltale signs of leakage. Sometimes, the leak is not visible to the naked eye. In such cases, you might notice corrosion or rust, which can suggest moisture presence over time. Regular inspection can help you catch these signs before they become serious issues.Pressure Drop Tests

Conducting a pressure drop test is another effective way to identify internal leaks. First, ensure the valve is closed completely. Then, monitor the pressure levels in the system. A consistent drop in pressure could indicate a leak. This test can be done using a pressure gauge attached to the system, allowing you to observe any fluctuations. It’s a practical step that can confirm your suspicions of internal leakage.Audible Indicators

Your ears can also be a valuable tool. Listen closely for any unusual sounds coming from the valve. A hissing noise might suggest air or fluid escaping, a clear sign of a leak. Trust your instincts if you hear something unusual. Sometimes, the smallest sound can alert you to a problem that isn’t visible. Being attentive to these noises can prevent bigger issues down the line. Have you ever caught a leak just by hearing a strange sound? It’s a reminder that sometimes, our senses provide the best warning systems. Keeping a vigilant ear can be just as important as what you see or measure.Quick Fix Techniques

Dealing with a ball valve leaking internally can be frustrating, especially when you’re aiming to maintain efficiency and avoid water wastage. Thankfully, there are quick fix techniques that can help you tackle this issue without having to call a plumber or replace the entire valve. These methods can save you both time and money, and might even make you feel like a DIY hero. Let’s dive into the practical solutions that can make your life easier.

Seal Replacement

One of the most common causes of internal leaks in ball valves is a worn-out seal. Replacing the seal can be a straightforward solution. You simply need to turn off the water supply first. Then, disassemble the valve and inspect the seal. If it’s damaged, have a new seal ready and replace it. This small change can often stop the leak entirely.

When choosing a new seal, ensure it’s compatible with your valve type. Having a mismatched seal might not solve the problem. A quick trip to your local hardware store or a search online can guide you to the right product. Don’t forget, a proper seal can extend the life of your ball valve considerably.

Lubrication Methods

Sometimes, a ball valve leaks internally because of stiffness or friction in the valve mechanism. Applying lubrication can solve this issue. A silicone-based lubricant is often recommended for ball valves. It helps the internal components move smoothly, reducing wear and tear.

Before you start, ensure the valve is dry and clean. Apply the lubricant sparingly to the moving parts. This technique can restore the valve’s functionality and might surprise you with how effective it can be. Who knew a little grease could go a long way?

Tightening Connections

A loose connection might be the culprit behind your valve’s leak. Carefully inspect the connections and tighten them as necessary. Use a wrench to secure the nuts and fittings, but be cautious not to overtighten. Over-tightening can cause damage or further leaks.

Think of this step as giving your valve a little TLC. A snug fit can prevent leaks and improve your valve’s performance significantly. Have you ever thought about how much difference a little tightening can make? It’s worth trying before considering more drastic measures.

These quick fix techniques are practical and accessible for anyone facing an internal leak in a ball valve. Next time you’re faced with this issue, remember these steps and give them a try. You’ll not only save water but also gain confidence in your DIY skills. What other small actions could make a big impact in your home maintenance routine?

Credit: plumberstar.com

Advanced Repair Options

Experiencing internal ball valve leakage can disrupt operations and lead to costly repairs. Exploring advanced repair options offers efficient solutions to fix this issue, ensuring smooth functionality and preventing future leaks. Proper maintenance and timely intervention are key to sustaining long-term valve performance.

When a ball valve starts leaking internally, it can disrupt the smooth operation of your plumbing or industrial systems. While temporary fixes might seem tempting, advanced repair options offer a more sustainable solution. These methods not only address the root cause but also enhance the valve’s lifespan and performance. Let’s dive into some of these advanced repair options that could save you time and resources.Professional Servicing

Seeking professional servicing can be a game-changer for your leaking ball valve. Experienced technicians have the tools and expertise to diagnose the issue accurately. They can perform precise adjustments or replacements that a DIY approach might overlook. Consider the last time you tried fixing a household appliance. Sometimes, professional help not only resolves the problem but also prevents future issues. Are you willing to invest in peace of mind?Valve Refurbishment

Valve refurbishment is a cost-effective alternative to replacing the entire unit. This process involves cleaning, repairing, and sometimes re-machining valve components to restore them to their original condition. Imagine giving your valve a second life without the hefty price tag of a new purchase. Refurbishment can be an ideal choice, especially for older or high-quality valves that are hard to replace. Wouldn’t it be satisfying to see your valve function as good as new?Upgrading Valve Components

Sometimes, the best solution is to upgrade the components of the valve. Modern materials and technologies can offer enhanced durability and efficiency. Replacing outdated parts with advanced alternatives can prevent future leaks and improve performance. Think about upgrading your smartphone for better features and speed. Similarly, upgrading valve components can bring noticeable improvements. Have you considered the long-term benefits of such enhancements for your system? Advanced repair options provide you with effective ways to tackle internal leaks in ball valves. By choosing professional servicing, refurbishment, or component upgrades, you’re not just fixing a leak—you’re investing in a long-term solution.Preventative Measures

Ball valves often serve as crucial components in piping systems. Preventing internal leaks ensures system efficiency and safety. Simple steps can help maintain valve integrity. Let’s explore some effective preventative measures.

Regular Maintenance

Schedule regular inspections to catch potential issues early. Routine checks help identify wear and tear. Clean valves frequently to prevent debris buildup. Lubricate moving parts to ensure smooth operation. Replace seals and gaskets when needed. Keeping a maintenance log aids in tracking performance.

Material Selection

Choose valve materials suited for your system’s fluids. Different materials resist corrosion differently. Stainless steel works well for corrosive substances. Brass suits less aggressive environments. Ensure compatibility with temperature and pressure requirements. Correct material choice prolongs valve life.

Proper Installation Practices

Ensure valves are installed correctly to prevent leaks. Follow manufacturer guidelines for installation. Verify that the valve is suitable for the intended use. Use appropriate tools to avoid damaging the valve. Tighten connections to recommended specifications. Proper support prevents undue stress on the valve.

Credit: zecovalve.com

Benefits Of Addressing Leaks

Fixing internal leaks in ball valves improves efficiency and prevents costly damage. It conserves resources and reduces utility bills. Regular maintenance ensures long-lasting valve performance.

Addressing leaks in ball valves is more than just a maintenance task; it’s a strategic move that offers numerous benefits. When you fix these leaks, you enhance the performance of your system, save money, and extend the life of your valve. This proactive approach can make a significant difference in the long run.Enhanced Efficiency

Leaking ball valves can disrupt the flow and pressure of fluids, causing inefficiencies. By addressing these leaks, you ensure optimal flow rates and pressure levels. This leads to a more efficient system that performs at its best. Think about it: have you ever noticed a sudden drop in water pressure at home? The culprit might be a minor leak. Fixing it restores normalcy and keeps your system running smoothly.Cost Savings

Every drop counts when it comes to leaks. Unattended leaks can lead to higher energy bills and increased maintenance costs. By fixing them, you save money on both fronts. Consider the cumulative effect of small leaks over time. They can add up to substantial losses. Addressing them early helps you avoid unnecessary expenses.Extended Valve Lifespan

Leaks can accelerate wear and tear on your valves. They subject your system to continuous strain, reducing the life expectancy of your components. Fixing leaks helps preserve your valve’s integrity. Imagine your valve as a reliable companion. With proper care, it can serve you faithfully for years. Addressing leaks is like giving it a much-needed tune-up, ensuring longevity and reliability. Have you ever thought about how a small leak today could impact your system tomorrow? Addressing it now could save you from bigger problems down the road.

Credit: www.youtube.com

Frequently Asked Questions

What Causes A Ball Valve To Leak Internally?

Internal leaks often occur due to worn seals or debris. These issues prevent a tight seal.

How Can I Identify An Internal Ball Valve Leak?

Look for decreased pressure or unexpected fluid flow. Inspect for moisture around the valve.

Can I Fix A Leaking Ball Valve Myself?

Yes, replace worn seals or clean debris. Ensure proper alignment during reassembly.

What Tools Are Needed To Repair A Ball Valve Leak?

You may need a wrench, screwdriver, and replacement seals. Always consult the valve manual.

Is It Safe To Use A Leaking Ball Valve?

No, leaks can cause damage or inefficiency. Prompt repair is recommended to avoid issues.

Conclusion

Fixing an internally leaking ball valve is crucial. It prevents bigger problems later. Regular maintenance helps avoid costly repairs. Check for wear and tear often. Replace faulty parts immediately. Use high-quality valves for durability. Always consult professionals for complex issues.

They ensure proper repairs and safety. Understand the signs of leakage early. This saves time and money. Proper care extends the valve’s life. Your plumbing system will work efficiently. Stay vigilant to keep your home safe. A well-maintained valve ensures peace of mind.

Keep learning for better maintenance skills. Your efforts will pay off in the long run.