Imagine turning on your faucet, expecting clean water, but instead, you get a mix of unexpected and potentially unsafe substances. That’s a scenario no one wants to face.

If you’ve ever wondered how such mishaps are avoided, you’re not alone. The secret lies in two crucial devices: the backflow preventer and the check valve. But what’s the difference between the two, and why should you care? Understanding how these devices work can save you from potential health hazards and costly repairs.

In this guide, you’ll discover the unique roles each plays in safeguarding your water supply. By the end of this article, you’ll know exactly which one you need to ensure your home’s water stays pure and safe. Ready to dive in and secure your peace of mind? Let’s get started!

Credit: zecovalve.com

Backflow Preventer Basics

Understanding the basics of backflow prevention is crucial for maintaining safe water systems. Backflow preventers are devices designed to stop contaminated water from reversing its flow. They play a vital role in protecting clean water supplies from pollutants.

What Is A Backflow Preventer?

A backflow preventer is a plumbing device. It ensures water only flows in one direction. These devices prevent unwanted reverse flow. They are essential in preventing contamination in water systems.

Types Of Backflow Preventers

There are various types of backflow preventers. Common types include pressure vacuum breakers and reduced pressure zone devices. Each type serves a unique purpose in preventing backflow.

How Backflow Preventers Work

Backflow preventers work by creating a barrier. This barrier stops contaminated water from entering clean water supplies. The mechanism relies on valves and pressure differences.

Installation Of Backflow Preventers

Proper installation is key for backflow preventers. They should be installed by professionals. This ensures they function correctly and safely.

Benefits Of Using Backflow Preventers

Backflow preventers keep water safe. They protect public health by stopping contaminants. This ensures a clean and reliable water supply.

Credit: plumberstar.com

Check Valve Fundamentals

Understanding the difference between a backflow preventer and a check valve is essential. A backflow preventer stops water from flowing backward into clean water supplies. Meanwhile, a check valve allows fluid to flow in one direction, preventing reverse flow. Both are crucial for maintaining safe water systems.

In the world of plumbing and fluid mechanics, understanding the basics of check valves is crucial. These simple devices play an important role in controlling the flow of liquids and gases. You might be wondering why you need to know about check valves. Imagine the frustration of dealing with a flooding basement or a malfunctioning pump. A check valve can be the unsung hero preventing such disasters. Let’s dive into the essentials of check valves and discover how they work.What Is A Check Valve?

A check valve is a one-way valve. It allows fluid to flow in one direction and prevents backflow. This is essential in systems where reverse flow could cause damage or contamination. Have you ever seen a swing door that only opens one way? That’s essentially how a check valve functions.Types Of Check Valves

Check valves come in various types. The most common ones include swing check valves, ball check valves, and diaphragm check valves. Each type operates differently. Swing check valves use a swinging disc, while ball check valves use a spherical ball to block reverse flow. Diaphragm check valves use a flexible diaphragm. Choosing the right type depends on your system’s needs.Applications Of Check Valves

Check valves are used in many applications. They are found in water pumps, gas lines, and even coffee machines. Picture your morning brew. A check valve ensures water flows in one direction, preventing backflow into the boiler. This helps maintain the taste and quality of your coffee.Importance Of Installing Check Valves Properly

Proper installation is key. A poorly installed check valve can lead to leaks or pressure buildup. This might result in costly repairs or system failure. Always follow manufacturer guidelines and consult a professional if needed. Your peace of mind is worth the extra effort.Choosing The Right Check Valve For Your System

Selecting the right check valve isn’t just about picking any valve off the shelf. Consider factors like pressure, temperature, and fluid type. Ask yourself: Will this valve handle my system’s requirements? It’s important to make an informed decision. You wouldn’t choose a flip-flop for hiking, would you? Understanding check valves can save you time, money, and headaches. Whether you’re a homeowner or a professional, knowing how these devices work helps ensure a smooth operation. Next time you encounter a check valve, you’ll appreciate its role in keeping everything flowing smoothly.Functionality Comparison

When it comes to plumbing systems, understanding the differences between a backflow preventer and a check valve can save you time, money, and potential headaches. Both are crucial components designed to manage the flow of water and prevent contamination. However, their functionality varies significantly. Let’s dive into how these devices operate and why choosing the right one matters.

Backflow Prevention Mechanisms

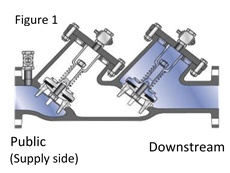

Backflow preventers are designed to stop water from flowing backward into your clean water supply. They act as a gatekeeper, ensuring that contaminated water doesn’t mix with potable water.

These devices often use a combination of valves and air gaps to create a physical barrier against backflow. This mechanism is particularly important in areas where water pressure can fluctuate.

Consider a scenario where you’re watering your garden. If the pressure drops suddenly, without a backflow preventer, water from your garden hose can siphon back into the main water supply, carrying fertilizers and pesticides. A backflow preventer blocks this reverse flow, protecting your home’s water quality.

Check Valve Operation

A check valve, on the other hand, is simpler in design. It allows water to flow in one direction only, using a hinged flap or ball to prevent reverse flow.

Its operation is straightforward: water pressure pushes the valve open, allowing water to pass. If the flow reverses, the valve closes, stopping any backflow.

This is particularly useful in systems where backflow isn’t a major concern, but you still need to ensure one-way flow. Imagine you’re filling your swimming pool. A check valve ensures water flows into the pool without being drawn back into the supply line.

Have you ever wondered why your neighbor’s garden hose doesn’t contaminate their water supply? The key is choosing the right valve for your needs. Whether it’s a backflow preventer or a check valve, understanding their functionality can safeguard your home’s water system. So, which one suits your setup? The answer lies in assessing your specific needs and water pressure dynamics.

Design And Structure

Understanding the differences between backflow preventers and check valves is crucial for safe plumbing systems. Backflow preventers protect against contamination, while check valves ensure one-way flow. Both are essential, but serve distinct purposes in maintaining water purity and system efficiency.

When you think about safeguarding your water system, the design and structure of the components you choose matter immensely. Backflow preventers and check valves are both essential tools, but they are crafted differently, impacting their functionality and application. Understanding their design nuances can help you make informed decisions about your plumbing needs.Components Of Backflow Preventers

Backflow preventers are complex devices with multiple components working together to ensure no contaminated water flows back into your clean water supply. They typically consist of: – Valves: Often two, working in tandem to seal the pipeline against reverse flow. – Test Cocks: Small valves used for testing the system’s integrity and ensuring it operates effectively. – Pressure Zones: Various zones within the device maintain a balance, preventing backflow through pressure differential. Imagine you’re managing a garden irrigation system. You wouldn’t want fertilizers and pesticides to seep into your home’s water supply. This is where backflow preventers shine, using their intricate design to keep your water safe and clean.Components Of Check Valves

Check valves, on the other hand, have a simpler structure, making them easier to install and maintain. They comprise: – Disc or Ball: A movable part that allows water to flow in one direction and blocks it from reversing. – Spring: Provides tension that keeps the disc or ball in place, ensuring the valve remains closed when no forward pressure exists. – Valve Body: Houses the components, typically made of metal or plastic, offering durability and longevity. Picture your home aquarium system. You want the water to circulate efficiently without backflow. A check valve can be your ally here, leveraging its straightforward design to facilitate smooth water movement without complications. Have you ever found yourself second-guessing your plumbing choices? It’s fascinating how design intricacies can influence their operation. As you delve deeper into your plumbing projects, consider what design elements best suit your unique needs.Installation Considerations

Understanding installation considerations is key for backflow preventers and check valves. Proper installation ensures effective performance and longevity. Both devices play crucial roles in preventing water contamination. Their installation requires careful planning and execution.

Placement In Plumbing Systems

Backflow preventers need strategic placement within plumbing systems. They protect water supplies from contamination. Install them at the point where non-potable water meets potable water. This placement ensures full protection. Check valves, on the other hand, prevent reverse flow. They are often installed in pipelines to maintain flow direction. Choose the correct location based on system design and function.

Space And Accessibility

Space and accessibility are critical during installation. Backflow preventers are larger and need more space. Ensure there’s enough room for maintenance and inspection. Check valves are usually smaller. They fit easily in tight spaces. Despite size, both require easy access for repairs. Consider their maintenance needs during installation planning.

Applications And Uses

Understanding the specific applications and uses of backflow preventers and check valves helps in choosing the right device for your needs. These components play crucial roles in plumbing and water systems, ensuring the safe and efficient flow of liquids. They might seem similar, but they serve different functions in various settings.

Common Uses For Backflow Preventers

Backflow preventers are essential in protecting water supplies from contamination. They are widely used in residential, commercial, and industrial plumbing systems. These devices prevent contaminated water from reversing into clean water supplies. In urban areas, backflow preventers are crucial for irrigation systems. They safeguard against fertilizers and pesticides entering the potable water. Hospitals and laboratories use these devices to protect sensitive equipment and ensure safe water supply. Fire sprinkler systems also rely on backflow preventers to maintain water purity.

Common Uses For Check Valves

Check valves are versatile and used in a range of applications. They allow fluid to flow in one direction and prevent reverse flow. In household plumbing, check valves maintain water pressure and prevent backflow. They are vital in water pumps, ensuring efficient operation by stopping backflow. In industrial settings, check valves are used in chemical processing. They prevent mixing of different chemicals, ensuring safety and efficiency. Heating and cooling systems also utilize check valves. They help manage the flow and maintain system integrity.

Maintenance And Longevity

Choosing between backflow preventers and check valves impacts both maintenance needs and device longevity. Backflow preventers typically require regular inspections to ensure optimal performance. Check valves, with fewer moving parts, often offer a longer lifespan but may lack the same level of protection.

When you think about your plumbing system, longevity and maintenance are two critical aspects that ensure everything runs smoothly. Backflow preventers and check valves are essential components in maintaining water safety and efficiency. But how do they fare in terms of upkeep and lifespan? Understanding their maintenance requirements can save you time, money, and hassle in the long run. Dive into the specifics of what each needs to perform at its best.Maintenance Requirements For Backflow Preventers

Backflow preventers play a crucial role in keeping your water supply safe from contamination. Routine maintenance is vital to ensure they function correctly. You should schedule an annual inspection to check for leaks, wear, or damage. Common issues include sediment buildup and corrosion, which can compromise performance. Regular cleaning and testing by a professional can prevent these problems. A well-maintained backflow preventer can last many years, making it a worthwhile investment.Maintenance For Check Valves

Check valves require less frequent maintenance than backflow preventers but shouldn’t be ignored. They are designed to allow water to flow in one direction, preventing backflow. Over time, debris can cause the valve to malfunction. Inspect your check valves every few years, or if you notice water flow issues. Simple cleaning or replacing worn-out parts can extend their life. Consider the effort you put into maintaining these components as an insurance policy for your plumbing system. Have you ever thought about how these components impact your water system’s efficiency and safety? Taking the time to maintain them properly can lead to fewer headaches and a more reliable plumbing experience.

Credit: www.safe-t-cover.com

Cost Implications

Understanding the cost implications of backflow preventers and check valves is crucial. These devices are essential in protecting water systems, but their costs differ. It’s important to know how each option can impact your budget. This includes both initial installation costs and long-term expenses.

Cost Of Installation

Installing a backflow preventer typically requires professional help. This can increase the cost significantly. The complexity of the installation often demands skilled labor. Check valves, on the other hand, are easier to install. This can mean lower initial expenses. They often require less specialized knowledge. This simplicity can appeal to budget-conscious consumers.

Long-term Cost Efficiency

Backflow preventers may have higher initial costs. But they offer significant long-term savings. These devices require less frequent maintenance. They are built to last longer. This durability can reduce replacement expenses over time. Check valves might have lower upfront costs. Yet, they can lead to more frequent repairs. Maintenance can add up, affecting long-term budgets. Choosing the right device depends on weighing initial and ongoing costs.

Regulatory Standards

Understanding regulatory standards is crucial when choosing between a backflow preventer and a check valve. These devices are essential for maintaining water quality and safety, but each has specific standards that govern their use. Are you aware of the regulations that ensure these devices perform their roles effectively?

Standards For Backflow Preventers

Backflow preventers are subject to stringent standards set by regulatory bodies. The American Water Works Association (AWWA) and the American Society of Sanitary Engineering (ASSE) have specific codes for these devices. These codes ensure they can reliably stop contaminated water from entering the clean supply.

Backflow preventers must be tested regularly to comply with local regulations. This testing is crucial to ensure the device’s effectiveness over time. Imagine discovering a failure in your backflow preventer during an inspection—it could lead to significant health risks.

Installation requirements are also detailed in these standards. The correct setup ensures optimal performance and compliance. Have you ever wondered if your installations meet these guidelines?

Standards For Check Valves

Check valves, on the other hand, have a different set of standards. The International Organization for Standardization (ISO) provides guidelines that focus on material quality and pressure capacity. These standards aim to ensure the valve can withstand operational demands without leaking.

Check valves are often tested for specific applications, like high-pressure environments. Regular checks can prevent unexpected failures in critical systems. Have you considered how often your check valves are evaluated?

Installation is straightforward, but placement is key to effectiveness. Ensure your check valve is installed in the right location to meet regulatory expectations. Are your check valves positioned to perform optimally?

Understanding these standards is not just about compliance; it’s about safeguarding your water supply. By adhering to these regulations, you can ensure that your systems function correctly and safely. Have you ensured your devices meet the necessary standards? The peace of mind that comes from knowing your water system is safe is invaluable.

Frequently Asked Questions

What Is A Backflow Preventer?

A backflow preventer stops dirty water from flowing back into clean water lines. Essential for water safety.

How Does A Check Valve Work?

A check valve allows water to flow in one direction only. It prevents reverse flow, protecting systems.

Do Backflow Preventers And Check Valves Differ?

Yes, they differ. Backflow preventers offer more protection against contamination. Check valves prevent reverse flow.

Can A Check Valve Replace A Backflow Preventer?

No, it can’t. Check valves don’t provide the same level of protection against water contamination.

Why Are Backflow Preventers Important?

They ensure safe drinking water. They prevent pollutants from entering clean water supplies, crucial for health.

Conclusion

Choosing between a backflow preventer and a check valve matters. Each has unique features and benefits. A backflow preventer offers strong protection for water systems. It ensures water flows in one direction only. A check valve, on the other hand, is simpler and cheaper.

It blocks reverse water flow effectively. Consider your system’s needs before deciding. Think about cost, complexity, and maintenance. Both options provide important functions. It’s crucial to ensure clean, safe water for your home or business. Make an informed choice. Prioritize safety and efficiency in your decision.